A well-sharpened toothed saw is not just a hand tool, it is practically a violin in the hands of a master. She does an excellent job, does not tear or crumple the edge, and the cut is clear and even. The secret is in good sharpening. But the constant use of the saw dulls the teeth and changes their setting. It is not so difficult to return your manual assistant to working condition; this can be done in literally half an hour with a simple tool.

Read in the article

- 1 Three types of hand saws: what are the differences

- 2 How can you sharpen a saw

- 3 How easy it is to spread the saw teeth

- 4 How to conveniently attach the saw for sharpening

- 5 Hand saw sharpening process: how to do it right

Three types of hand saws: what are the differences

For those who did not know, we inform you: hand saws are divided into three types. Some of them are designed for cutting wood across the grain, others for working along, and there are universal saws that can cope with both tasks. It is the universal ones that are most common. And it is quite simple to determine the type of saw: the teeth of the cross-cut tool have the correct shape, for longitudinal - a strong bevel in one direction, universal have one face at a right angle, and the other - beveled. Cross-cutting is carried out in two directions, that is, the saw blade moves back and forth, with a longitudinal saw, the saw only works in one direction. Accordingly, when sharpening teeth, these nuances must be taken into account.

How can you sharpen a saw

Hand saws are made from corrosion-resistant alloy steel. This material perfectly retains its sharpening during constant use and does not lose it, even if the hacksaw is not used for a long time. The exception is some modern models, in which the edge is hardened, this cannot be diluted or sharpened without preliminary annealing.

With a certain skill, you can sharpen a saw and an electric sharpener with a circle up to 8 mm thick made of white stone on vulcanite with a grain of 120-140 and a diameter of 120-160 mm.

How easy it is to spread the saw teeth

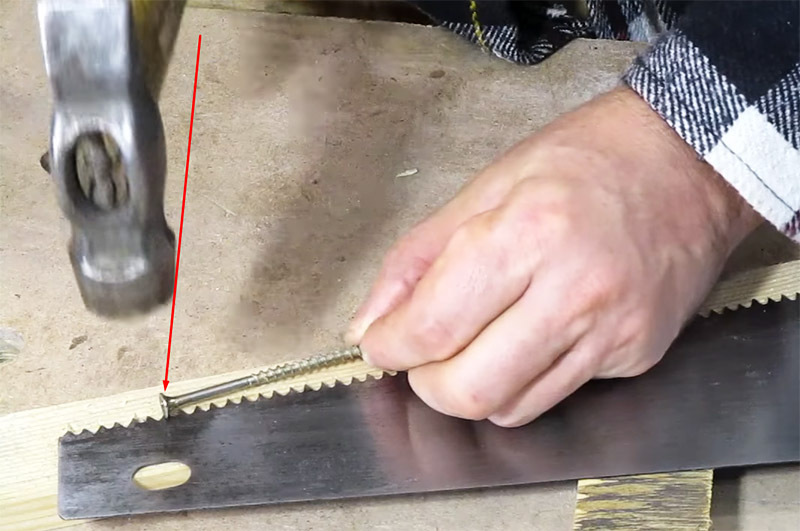

Before starting sharpening, the teeth must be returned to the working position, that is, diluted. The easiest way to do this is with a regular hammer, nail or self-tapping screw and a softwood plank.

The spreading must be done before sharpening, so that later not to damage the edge of the tooth and so that the setting is even, which is difficult to achieve later.

How to conveniently attach the saw for sharpening

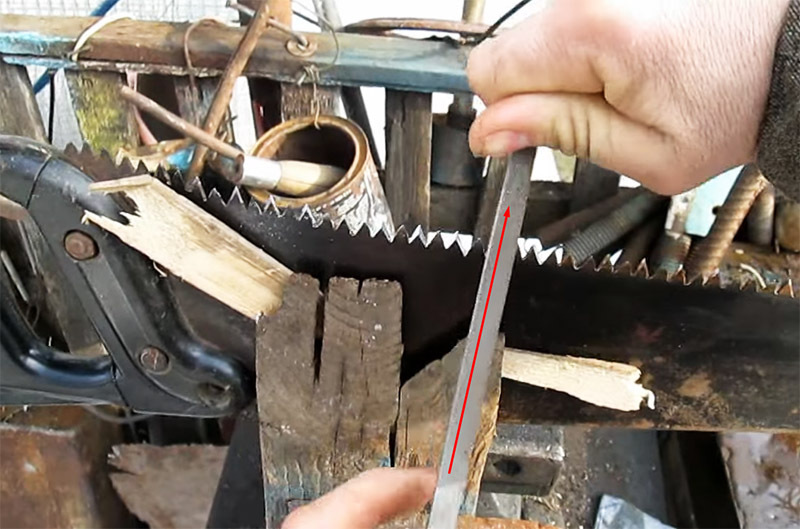

To work with a file or a file, the hacksaw blade must be in a strictly vertical and firmly fixed position with the teeth up.

Hand saw sharpening process: how to do it right

First of all, carefully inspect the saw and find the teeth least affected by the work to determine the sharpening angle. This can be done simply by attaching a metal ruler.

How to sharpen a saw with an abrasive wheel - in this short video:

How do you sharpen a saw? Do you have your own tools or sharpening secrets? Share your experience in the comments!