Electric welding Is a way of connecting various parts and surfaces, which is in demand almost always and everywhere. The ability to cook is especially important in the production of various construction or repair work in the country or in a private house. Do not think that after reading a couple of articles, you can learn how to weld metal normally - this takes time and practice. But having studied and understood the basic rules of how to properly carry out welding work, how to keep electrode and set the required current, it is quite possible at least to learn how to connect non-bearing elements designs. And the rest will come with experience.

Read in the article

- 1 Equipment, outfit and consumables that will be required for welding

- 1.1 Welding machine: types, features of use

- 1.2 Personal protective equipment when working with welding

- 2 How welding works: general information

- 2.1 The choice of amperage for ignition and maintenance of the optimal arc

- 2.2 Inclination and movement of the electrode when welding metal

- 3 Welding work with different seam arrangements

- 4 Welding of various types of joints

- 4.1 Butt joint: the nuances of welding

- 4.2 Overlapping parts welding

- 4.3 T-joint

- 5 Pipelines: features of the production of welding works on them

- 6 Let's summarize the information presented

Equipment, outfit and consumables that will be required for welding

For the production of welding you will need:

- the welding machine itself;

- welding robe, gloves or mittens;

- protective mask;

- electrodes.

At first glance, everything is simple. However, you should understand this list in more detail.

Related article:

How to choose the right inverter welding machine: which is better for home and summer cottages, the criteria for making the right choice, as well as the secrets of use, you will learn after studying the materials of this article.

Welding machine: types, features of use

Welding machines for manual arc welding can be of three types - transformer, inverter and semiconductor (rectifier). Working with each of them requires a special approach.

Transformer type device - this is the simplest device, which has a built-in step-down transformer. As a result of its operation, the current strength increases significantly, which allows you to ignite the arc. These welders require the ability to adjust the output current to optimize welding.

Semiconductor or rectifier devices. In fact, this is the same transformer welder with the only difference. The outgoing current from the transformer passes through the rectifier, which improves the quality of the welds and simplifies the work.

Inverter apparatus more modern version. Such a welder is very compact and lightweight. For novice welders, this will be the perfect purchase. Thanks to cascade converters, an even current can be obtained at the output, which is regulated by a rheostat much more accurately than it could be done on previous devices.

Personal protective equipment when working with welding

Along with special suits, gloves and shoes, when performing welding work, it is necessary to use a welding mask with a light filter. If we talk about such protection of the previous generation, then the light filter was a glass through which it is impossible to see anything unless you look at the arc. Only because of its high brightness, the welder could see the seam with which he was working. Modern light filters allow you to see everything around perfectly, but instantly darken at the slightest spark from the electrode.

PPE should fully protect the welder's body, and most importantly, help avoid burns to the retina. A similar problem among the "welded fraternity" is called "grabbing bunnies." The result of the burn is severe pain, pain, and a feeling of sand in the eyes. In difficult cases, a sharp decrease, and sometimes a complete loss of vision, is possible.

How welding works: general information

Before starting work, it is necessary to prepare the welding machine. To begin with, the tightness of all connections and the integrity of the cable insulation are checked, as well as the strength of the electrode fixation in the holder. After that, the welding machine is connected to the network. For the welder, this is the only thing that he has to check for himself. Periodic checks (at least every six months) must be carried out by an electrician.

The choice of amperage for ignition and maintenance of the optimal arc

In order to correctly set the required current, you must first determine the diameter of the electrode used, which, in turn, depends on the thickness of the metal being welded. It is worth considering the table of the ratios of these parameters.

Table 1. The ratio of the diameter of the electrode to the thickness of the metal in arc welding

| Metal thickness, mm | 1-2 | 3 | 4-5 | 6-8 | 9-12 | 13-15 | 16 and more |

| Electrode diameter, mm | 1,5-2 | 3 | 3-4 | 4 | 4-5 | 5 | 6 |

The output current is also set depending on the electrode. It is calculated by the formula I = dKwhere the value K must be taken from the table.

Table 2. K values for different electrodes

| Electrode diameter, mm | 1-2 | 3-4 | 5-6 |

| Proportionality coefficient (K), A / mm | 25-30 | 30-45 | 45-60 |

Experienced welders no longer bother with calculations, keeping in mind the approximate range of currents. All they need is a minor tweak on the fly.

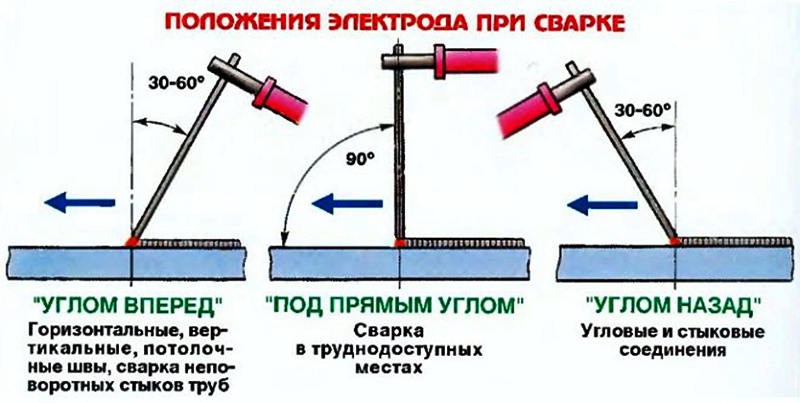

Inclination and movement of the electrode when welding metal

The complexity of the work depends on the inclination of the electrode during welding. For example, a beginner is unlikely to be able to lead the electrode perpendicular to the surface. This method requires certain skills and experience.

For beginners, it will be more acceptable to tilt the electrode backward. With this arrangement, the slag will remain behind the arc. Slightly harder is the forward angle. Here you will need to independently choose the slope so that the slag does not fill the bath along the seam and does not extinguish the arc.

Welding work with different seam arrangements

The seam to be welded can be located:

- vertically;

- horizontally;

- in an inclined position;

- above the worker (ceiling seam).

The simplest, and therefore requiring less skills, are horizontal seams. Further, as the complexity increases, there are inclined, vertical ones. The most difficult is the ceiling seam. Only qualified welders can work with it, therefore, if the home craftsman does not have experience in such welding, it is better not even to try to perform it. Nothing but drops of molten metal behind the collar will come of it.

Welding of various types of joints

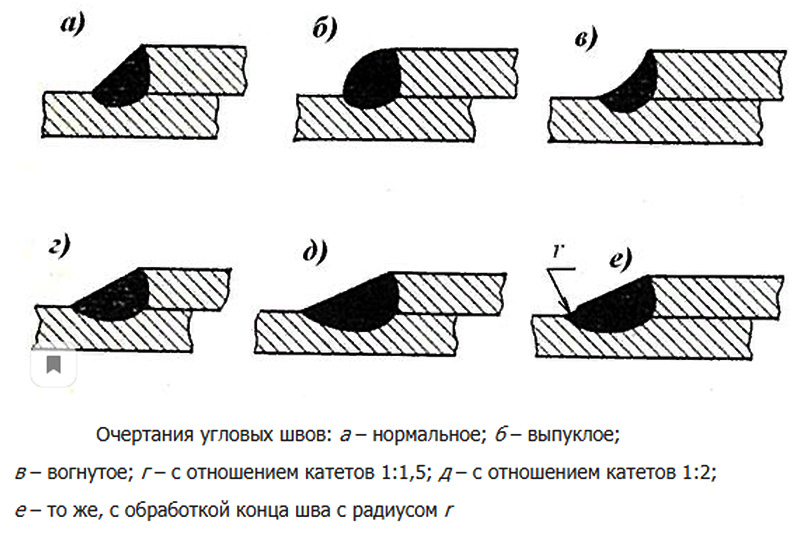

The seams can be structurally different from one another. In this case, metal parts can be located end-to-end or overlapped. Tee seams are also distinguished. It makes sense to understand the features of each of them.

Butt joint: the nuances of welding

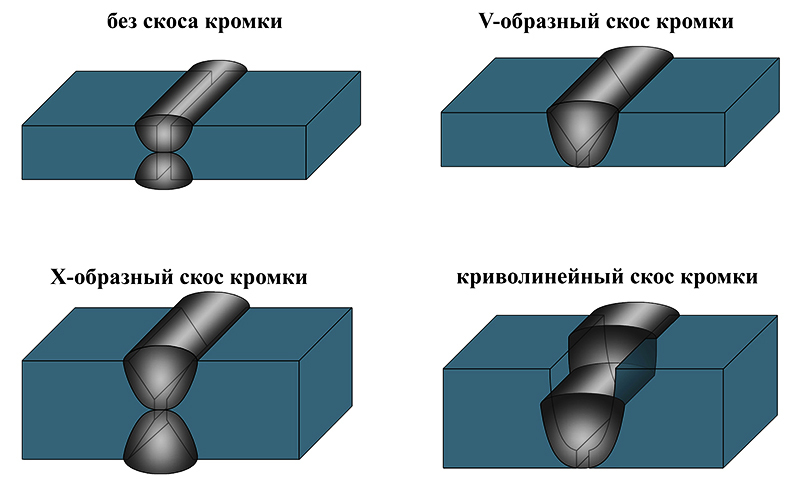

When welding butt-welded metal, preparatory work depends on the thickness of the parts. If it is large, then there is a danger of "lack of penetration", which will lead to unreliability of the connection. In this case, the edge of the part at the welding point is ground at an angle so that a groove is formed when the workpieces are aligned. The hem can be removed from one side of the seam, or from both. When the electrode moves along the groove, maximum welding is achieved, and a strong non-separable connection is created.

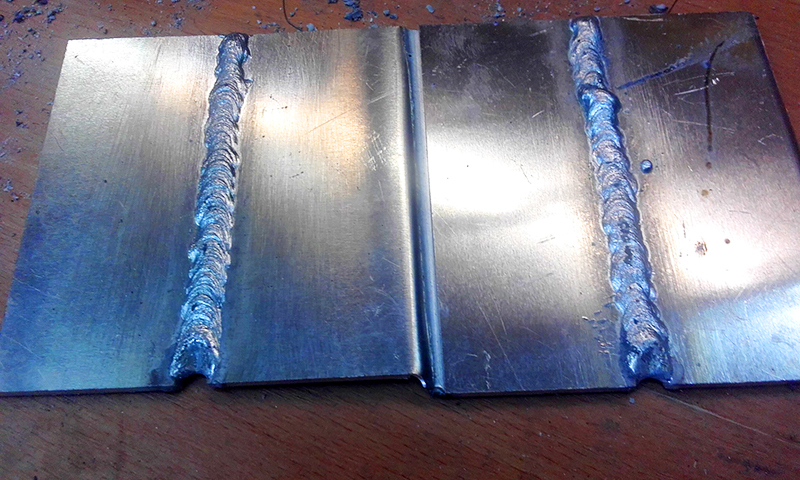

Overlapping parts welding

The simplest connection for craftsmen who have no experience in welding. This option does not require any special preparation of the metal. In this case, you can weld on several layers, superimposing one on top of the other with an increase in the diameter of the electrode. The main thing to remember is that the slag must be removed after each of the layers.

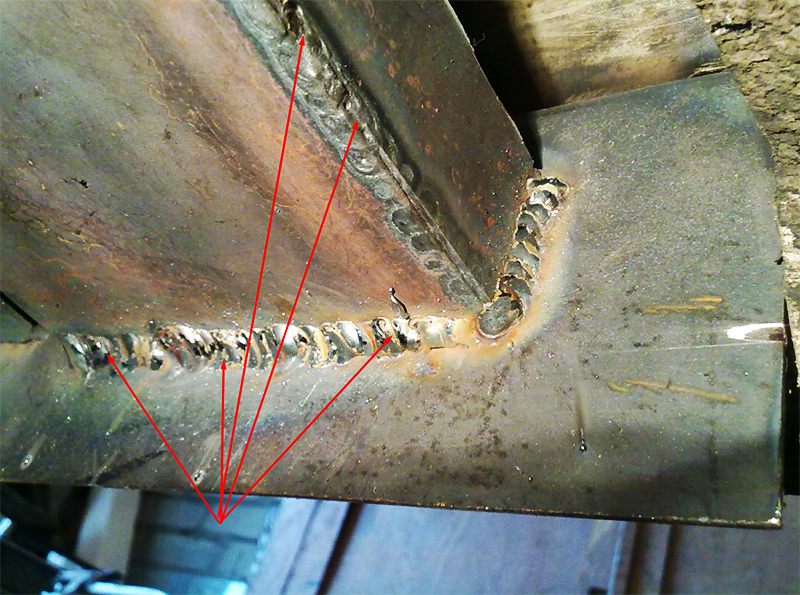

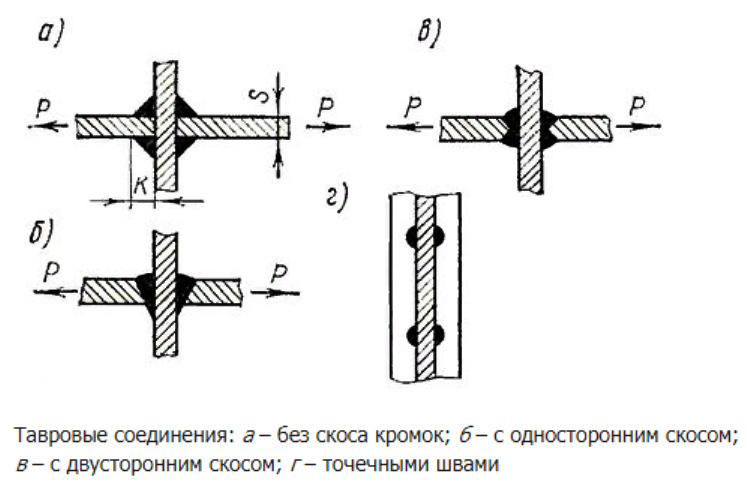

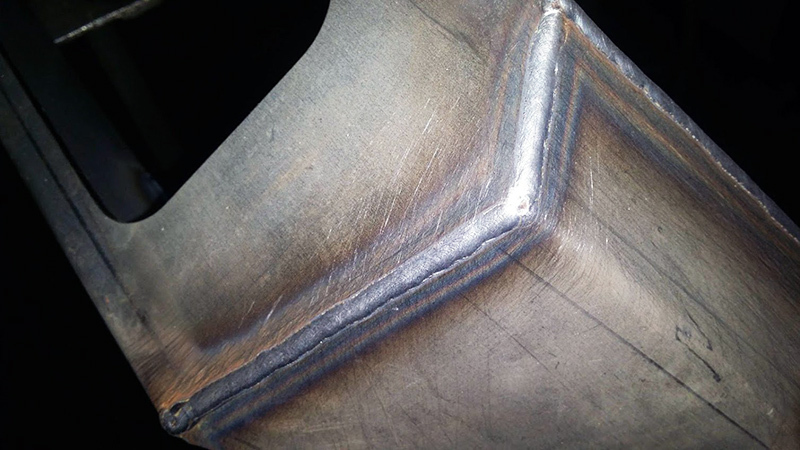

T-joint

For the production of a T-joint, no preparation of the metal edges is required, although in some cases they are still removed. Such connections are made when it is necessary to install elements located in perpendicular planes. For example, you can pay attention to the photo below.

Pipelines: features of the production of welding works on them

Welding of main pipelines is quite difficult. It requires the obligatory presence of an experienced specialist. Therefore, if a home craftsman is just starting his studies, he should not take on responsible areas (like a water supply in an apartment or a private house). In this case, it is better to do with replacing all metal pipes with polypropylene and already solder the line from them. No special experience is required here; you can quickly learn how to make high-quality soldering of polypropylene.

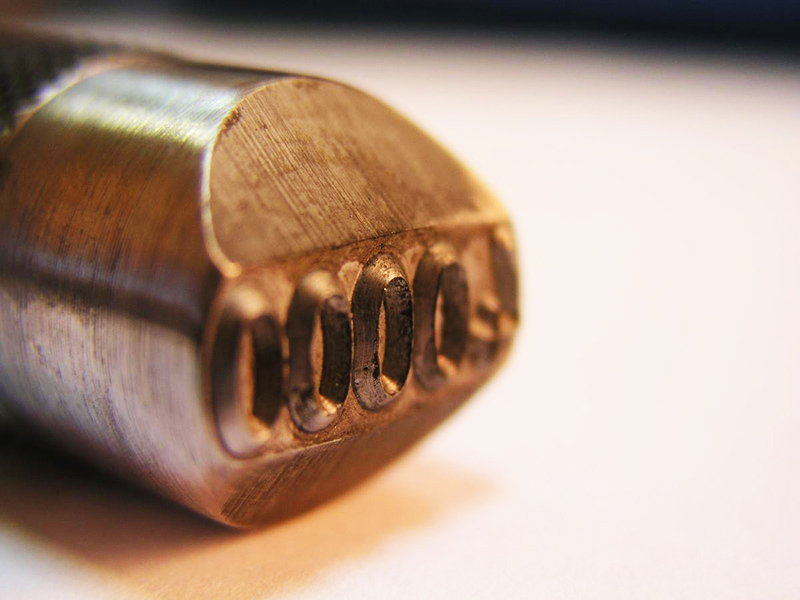

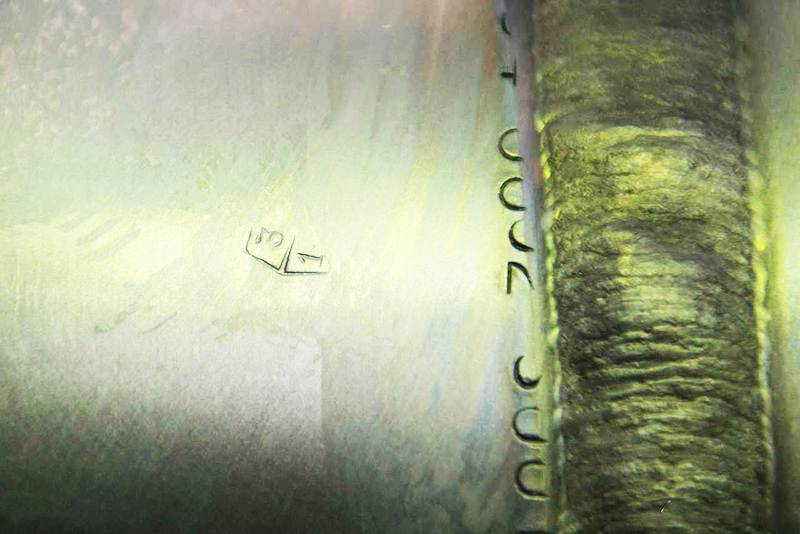

For pipelines from half an inch or less, it is best to use gas welding, but thicker pipelines are mounted exclusively using an arc. Depending on the degree of responsibility of the line to be installed, the welder may be required to have a NAKS (National Welding Quality Agency) certificate. According to the results of certification by NAKS, the welder can receive a personal stamp, which consists of digital and letter designations. Subsequently, upon recertification, it does not change. Specialists with a personal mark and a NAKS certificate can work on the installation of gas and oil pipelines. The welder's mark on the seam is a kind of quality mark.

For those for whom working professions are akin to art, we can say this - the welder's stamp is the signature of the artist who created the canvas. In fact, the profession of a welder implies a creative approach, a little limited by the framework of the rules. Below you can see what seams can be made by specialists certified by the NAKS.

1 out of 6

PHOTO: disolen.lv

PHOTO: formation-soudure.com

PHOTO: fishki.net

PHOTO: intertechpribor.ru

PHOTO: promtu.ru

PHOTO: mani.by

Let's summarize the information presented

Any working profession requires training and compulsory practice. If we talk about welding, then here this statement is doubly true. Of course, a home craftsman can learn the basics of this profession and gradually gain experience, but this is not a matter of one day or even a month. Professionals with a personal stigma and having worked for more than a dozen years claim that they never stop learning this complex, but very interesting and creative craft.

And for yourself, in a workshop or garage, you can completely master welding so that you can independently connect structural elements that do not require much responsibility. The main thing is to comply with all the rules for the production of work and do not forget about safety precautions.

We hope that from today's article the reader will gather for himself a certain amount of useful information. If you have any questions on the topic, you can ask in the comments below. The editors of the online magazine HouseChief will be happy to answer them as soon as possible. There you can also leave a review about the article, expressing your opinion. If you liked what was stated today, please do not forget to rate it.

Finally, as has already happened, we bring to your attention one video that will not take much time to viewing, but will help to more fully understand such a complex, but interesting topic of the production of welding works.