During operation sewerage system not infrequently blockage occurs. This does not reflect in the best way on the convenience of living, since all the contents of the pipes end up in the apartment. To prevent this from happening, it is worthwhile to purchase and install a check valve for the sewage system in advance. Manufacturers offer different types, the purpose of each of which is to prevent the ingress of drains into the home. To choose the right option, it is worth getting acquainted with the existing varieties and their distinctive features.

Read in the article

- 1 Check valve for sewage: purpose, what are the types

- 2 Device and principle of action by type

- 2.1 Swivel

- 2.2 Lifting

- 2.3 Ball

- 2.4 Interflanged

- 3 Manufacturing materials

- 4 General specifications

- 5 Advantages and disadvantages

- 6 Dimensions (edit)

- 7 How to choose a sewer check valve: general tips

- 8 Place of installation

- 9 Mounting

- 9.1 Tools and materials

- 9.2 Step-by-step instruction

- 10 Possible connection errors

- 11 Operation and maintenance

- 12 What to do if the check valve is damaged

Check valve for sewage: purpose, what are the types

The main purpose of any check valve for sewage is to shut off the flow of liquid moving in the opposite direction along sewer pipes. This happens mainly if characteristic deposits appear on the horizontal section of the pipe, or a plug forms. The fluid has to move in the opposite direction in search of an exit outside the contour. That is why a check valve is installed on the first floors of multi-apartment buildings, thereby preventing ingress sewage drains inside the apartment. If you have one, you do not have to worry that the contents of the toilet will end up on the floor.

This element is also relevant for the upper floors in the event that the blockage occurred not in the basement, but between floors due to violation of the rules for operating the sewage system. In this case, the "breakthrough" of drains can occur anywhere in the riser. Therefore, it is advisable to install a check valve on each floor in order to prevent possible negative consequences.

A sewage check valve is also relevant for owners of private houses. If during the design of the system only a direct stroke was not provided, and there is a possibility of a return of the drain, this element will prevent such a negative phenomenon. Also, it will not allow you to penetrate through the pipes into the house. rodents and other animals.

Device and principle of action by type

The principle of operation of the valve directly depends on its design. Choosing a suitable option, it is worth getting to know the existing ones, having analyzed their distinctive features. This will allow you to make a choice in favor of the optimal model.

Swivel

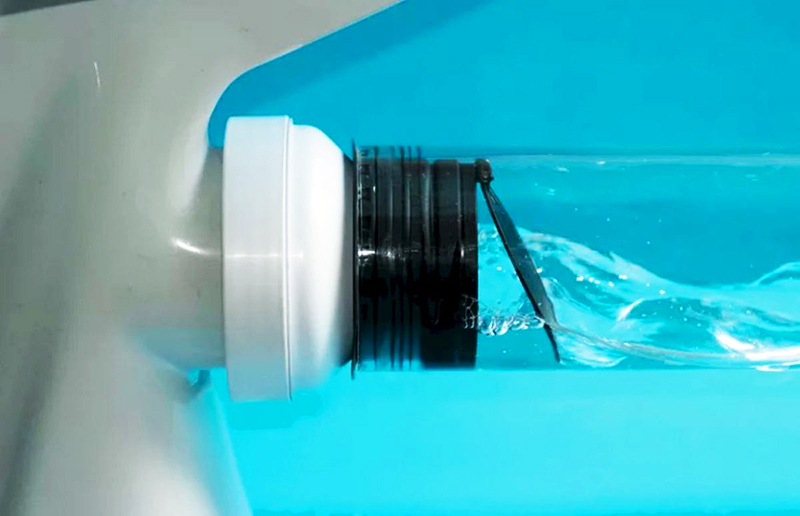

For products of this type, a membrane acts as a locking part, which is sometimes called a plate, reinforced by a spring. It is shaped like a petal. When the drains move down, the rounded flap turns, moving. As a result, its presence does not interfere in any way with the passage of wastewater to the outside. The spring is compressed by hydraulic pressure, which gradually builds up mechanical stress. As soon as the pressure decreases, the spring unfolds, blocking the passage. In the absence of drains or their movement in the opposite direction, the spring fixes the petal, and it is constantly pressed against the rim of the device.

A comment

Vladislav Mikhaltsev

Locksmith for the operation of water supply and sewerage systems, LLC "GK" Spetsstroy "

“Some models have an additional manual diaphragm. If it is available, it is enough to press the button from the outside to close the opening ”.

The cross-sectional dimensions of the swing check valve are larger than the cross-sectional dimensions of pipelines. This often causes constipation. To service the device, a technological cover is provided in the upper part. Having removed this element, you can rinse the walls and clean the lumen.

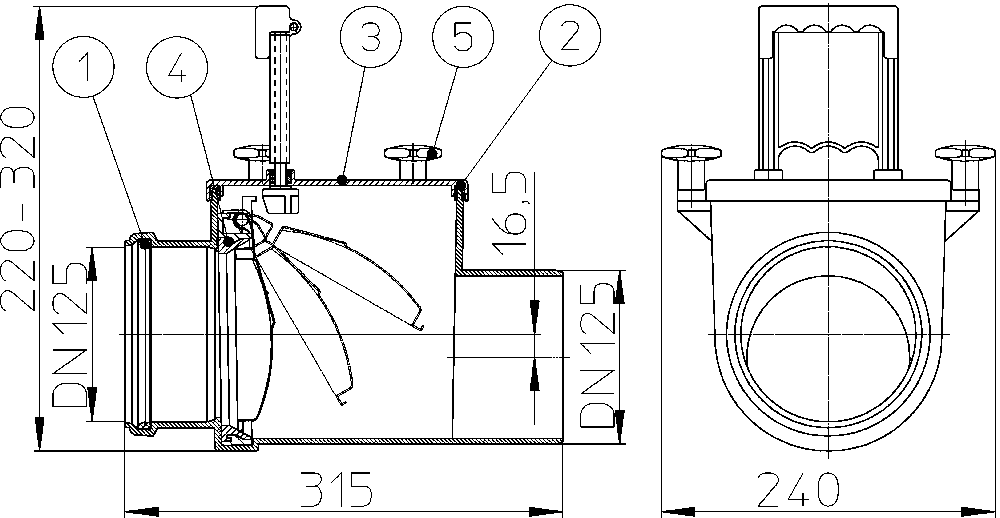

Lifting

In lifting-type devices, the element covering the opening does not rotate with respect to the flow, but is shifted to the vertical plane. Thanks to this design solution, the inlet of the drain is located below the outlet. If the masses are moving in the right direction, the pressure generated by them compresses the spring connected to the end cap. As a result, the latter begins to rise and is pressed against the rim of the pipe. In the event of reverse movement of drains, a tightly pressed flap prevents them from entering the toilet.

In terms of reliability, lifting products are significantly superior to rotary ones. However, they are more likely to clog up during operation. To clean it, just unscrew a few bolts and then remove any accumulated debris.

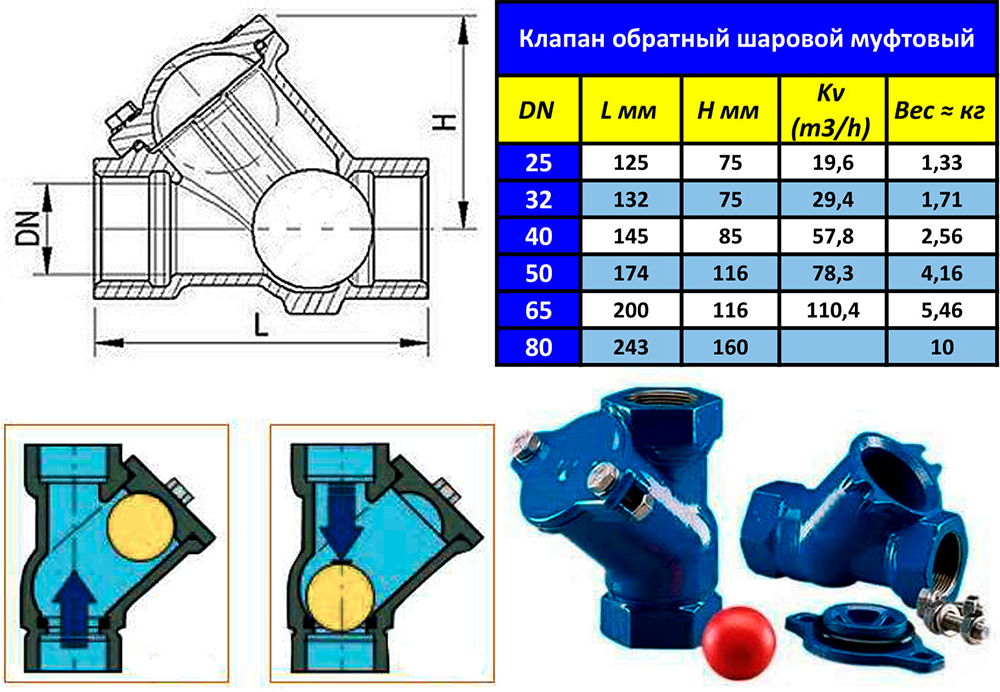

Ball

Balls use a large plastic ball as an overlapping element. Its upper part is designed in such a way that when the wastewater flows directly through the sewer, the ball is inside a special recess. It is located at the top of the pipe. The obstacle is displaced by an amount equal to the flow diameter. The extra articulation between the inlet rim and the recess makes it easier to move the ball. With the reverse movement of drains through the sewer, the ball cannot rise up due to the lack of a slope.

Ball check valves are built into the pressure sewerage system. The flow generated by the pump reliably holds the barrier element in the recess. It is better not to purchase products of this type for private houses. Here the drains are moved by gravity. The force generated may not be sufficient for the stable operation of the device. As a result, some of the waste water can leak in the opposite direction.

Interflanged

Such devices are attracted by their small dimensions. The working part is a flap that rotates relative to the normal flow of fluid. As a fastener for it, a horizontal rod is used, located in the very center of the passage. This constipation consists of two semicircular parts. If the barrier element is made in the form of a solid plate, a tight spring is used to secure it.

Such devices are of limited use due to the complexity of cleaning. To restore the functionality of an element, it must be completely disassembled. That is why such devices are most often part of the water supply system, and not the sewage system.

Manufacturing materials

In the manufacture of a check valve for sewerage use:

- polypropylene;

- polyvinyl chloride (PVC);

- bronze;

- cast iron;

- plastic, including impact resistant ABS;

- stainless steel.

In some models, one material is used for the manufacture of the product body, and a different material for the shutter.

General specifications

The general technical characteristics of check valves include:

- nominal diameter (DN). It varies in the range of 50 - 300 mm and indicates the size of the section of the connecting pipes;

- nominal pressure (PN). This characteristic shows the maximum overpressure of wastewater at a temperature of 20 ° C;

- flow factor (Kvs). Characterizes the consumption of waste masses passing through the device at a temperature of 20 ° C;

- Operating temperature range. Defines the purpose of the device. Depends on the type of material that was used in the manufacture of a particular check valve;

- type of instalation. It can be vertical and horizontal.

Advantages and disadvantages

The advantages of a check valve for sewage include:

- simple design;

- simple installation and subsequent maintenance;

- efficiency and reliability of work;

- reliable protection of the premises from possible flooding by sewage;

- durability.

Among the disadvantages, it is worth noting the high cost and the need for periodic maintenance due to pollution.

Dimensions (edit)

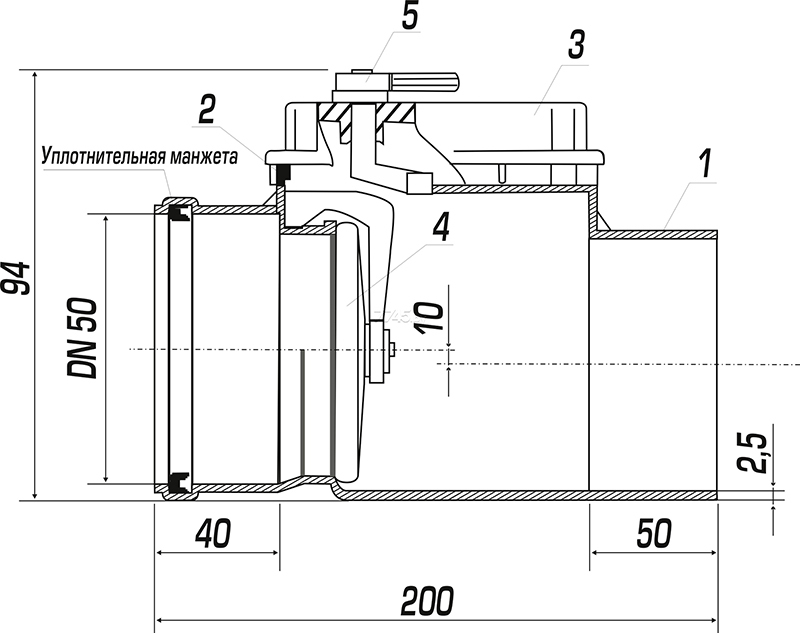

The geometric parameters of the sewage check valve are closely related to the transverse dimensions of the pipes on which they will be installed. In the catalogs of manufacturers, you can find products with a diameter of 32, 40, 50, 90, 110, 160 mm and other transverse dimensions.

Check valves with a diameter of 50 mm are installed on the internal networks of residential buildings. Toilets are fitted with products with transverse dimensions of 110 mm. Such models are ideally matched to the parameters of standard PVC pipes and are able to withstand significant pressure.

How to choose a sewer check valve: general tips

To find a suitable check valve for the sewage system, you should pay attention to:

- pipe diameterfor which it is intended. Most valves are socket oriented;

- valve material. As a rule, manufacturers offer plastic models focused on the sewage system from the same material. If the sewage system consists of cast iron pipes, the check valve must also be cast iron. It is possible to insert a polymer product using a special transition cuff. Flaps for quality models are made of stainless steel;

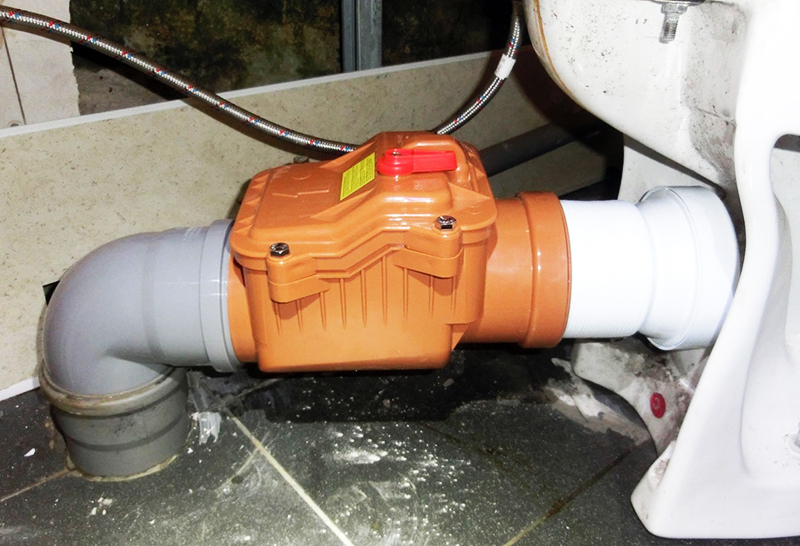

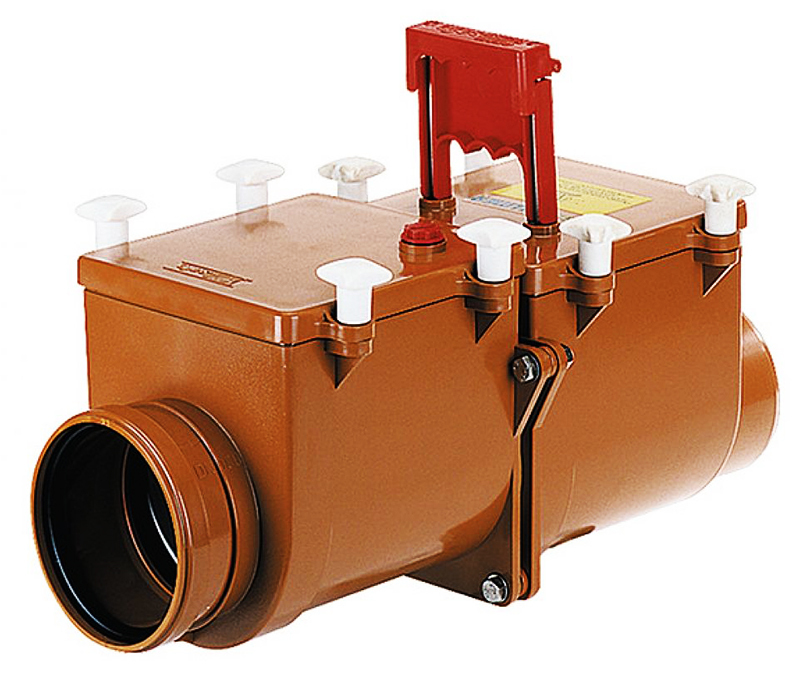

- appointment. Indoor models are available. They are usually gray in color. There are universal ones. These can be mounted inside and outside the building. They are colored orange. Thanks to the use of more durable materials, such products can withstand significant temperature fluctuations and stress;

- device functionality. In the parameters of a particular model, it is indicated whether it is designed only for the passage of water or is able to cope with fecal waste. It is also worth paying attention to the permissible spatial position during the installation process. There are products focused on installation only in a horizontal position, others - only in a vertical position;

- product dimensions. Especially if the installation will be carried out in a confined space;

- maximum allowable pressure. If the specified parameter is exceeded, the damper can deform under the influence of the applied load;

- availability of the possibility of forced shut-off of the valve. This function is relevant for private houses;

- manufacturing company. There are products of domestic and foreign brands on sale. When choosing a specific option, you should pay attention to the availability of the warranty and its duration.

Place of installation

Due to its large dimensions, it can be quite difficult to choose a suitable place for installing a check valve for the sewage system. Most often, it is mounted in front of the entrance to the riser. However, this is often associated with a number of difficulties due to the need to dismantle the already laid tiles.

If this option does not suit you, you can choose the riser above the entrance as the installation site. This option will require written permission to intervene in the common house system. Before starting work, in this case, you will have to notify the residents and turn off the water. This can only be done by representatives of the relevant services. Taking into account the listed difficulties, this option is used very rarely.

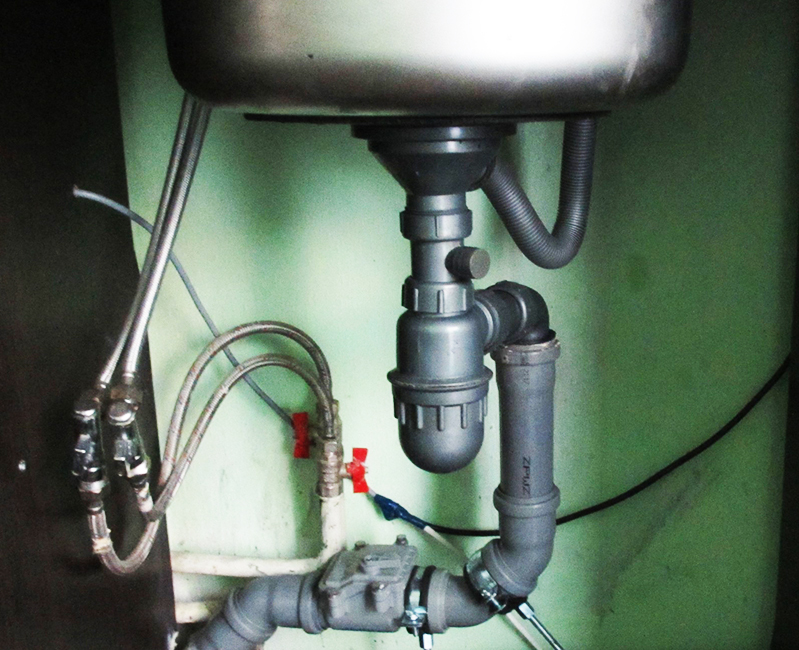

If you cannot find a suitable place for placement, you can install compact models on each plumbing fixture, if there is a separate pipe connection to them. Otherwise, two are enough: on the toilet and on a branch that diverts wastewater from other devices.

Mounting

In order to properly install a check valve for the sewage system, it is worth getting to know its design features. Different types have a number of their own distinctive features that determine the order of installation work. It is worth getting to know them in advance.

Tools and materials

To install a sewage check valve, you must have:

- torque or wrench;

- roulette;

- fum tape. In its absence, you can use flax fiber;

- special sealant.

Step-by-step instruction

The work is performed in the following sequence:

- notify other residents of the upcoming work. This is done in a day;

- cold and hot water is shut off;

- at the place of work, a part of the pipe is cut out, the length of which corresponds to the length of the valve;

- threads are cut at the ends of the pipes. The shavings must be removed;

- fum tape or linen fiber is wound on the threads;

- a layer of sealant is applied on top of the sealant;

- screw on the valve. Tighten the fasteners carefully using a wrench.

Possible connection errors

Often, when performing installation work, typical mistakes are made. These include:

- lack of alignment between the check valve and the pipeline at the connection point. This can cause leakage during operation;

- inconsistency between the direction of opening of the flaps and the direction of movement of the direct flow of wastewater. In this case, the check valve will work in the opposite direction;

- impossibility of maintenance of the device due to lack of access.

Operation and maintenance

The service life of the sewage check valve largely depends on compliance with the manufacturer's care requirements. The device installed in a private house should be cleaned at least 3-4 times a year. In an apartment building - at least once, but better than 2 times a year.

What to do if the check valve is damaged

If an extraneous squeak, rattle or other noise appears during operation, check the serviceability of the check valve and carry out unscheduled cleaning. The frequency of wear of various parts is given in the instructions for the device.

Attention! Some worn parts cannot be replaced. In case of their failure, you will have to replace the entire product.

Share in the comments if you have installed a sewer check valve at home? What type of equipment did you prefer? Does the chosen model cope with the possible problem?