The compact size of some models allows them to be used in any environment

CONTENT

- 1 Design and operation - basic knowledge required

- 2 Types of table grinders - distinctive features and useful properties

- 3 Universal grinder

- 4 What to look for when choosing: basic technical characteristics

- 5 Which desktop grinding machine is better to buy in 2019: choosing the best models in the Russian market

- 6 Is it worth buying equipment for sharpening cutting tools

Design and operation - basic knowledge required

First of all, let's figure out what a grinding machine is in structural terms and how it works. Externally, this unit is an electric motor hidden behind a steel case, on both sides of which there are grinding wheels.

During operation, the motor makes rotational movements of a certain speed, forcing the abrasive elements to do the same. For sharpening, you just need to bring the cutting edge to the emery equipment and hold the tool in your hands until the required sharpness and smoothness of the metal is achieved.

Always remember the safety rules. Remember to wear personal protective equipment when using grinding equipment (at least glasses and gloves). Avoid the presence of flammable materials nearby - sparks are generated on contact with metal.

Types of table grinders - distinctive features and useful properties

Despite the simple device and principle of operation, the hero of our review has his own classification. This is due to the abundance of cutting tools used in modern construction and industry.

Specialized grinding machine

This modification works only with certain surfaces, but allows you to achieve better results when processing. Such equipment most often refers to professional equipment, rather than household equipment - this affects both the range and the price. Among specialized grinding machines, several subspecies can be distinguished:

| Machine type | Description |

| Sharpener with engraver | Allows you to give metal and other materials a certain shape and apply inscriptions on their surface |

| Device for sharpening knives and scissors | Works only with the specified devices, they must be sharpened strictly at a certain angle in relation to the abrasive |

| A device for working with chains of electric and gasoline saws | Serves for processing chain saw teeth with various power sources, also requires a certain skill |

| Drill grinder | It makes it possible to return the former cutting properties to drills of any diameter, very popular in mechanical engineering |

The option for processing the edges of knives and scissors is the simplest and most affordable, but at the same time its functionality is not so wide

Universal grinder

Such a model, as it is not difficult to understand from the name, will allow you to perform all the operations described in the previous paragraph. At first glance, this seems like an ideal solution. But a hefty "fly in the ointment" is brought in by the following factor: an electric tool will be more susceptible to various breakdowns and failures. This is due to multitasking - other electrical and electronic devices "sin" with similar problems. But you can simultaneously perform both rough and fine surface treatment.

What to look for when choosing: basic technical characteristics

Any modern technology has several important parameters that directly affect their performance, durability and ease of use. Our "subject" was no exception. Therefore, now we will consider the most important indicators, the observance of which is necessary under any circumstances.

Engine power

The speed of rotation of the spindle on which the emery wheel is fixed directly depends on this characteristic. As a result, you can even sharpen products from high-strength steel grades. For household use, a power of 500-800 W is quite enough, but if a large amount of work is planned, it is worth considering professional options.

"Ordinary" models for everyday use operate on a standard 220V power supply

Abrasive wheel speed

We think that in this case, too, everything is clear - the more turns the sharpener makes, the stronger the processed material can be. But at the same time, high speeds require both greater wear resistance of all structural elements, and huge energy consumption.

TOINFORMATION!

Since sparks are created when a metal comes into contact with an abrasive at high speeds, our editors recommend choose machines equipped with special protective glass - it additionally protects your skin and eyes from possible injuries.

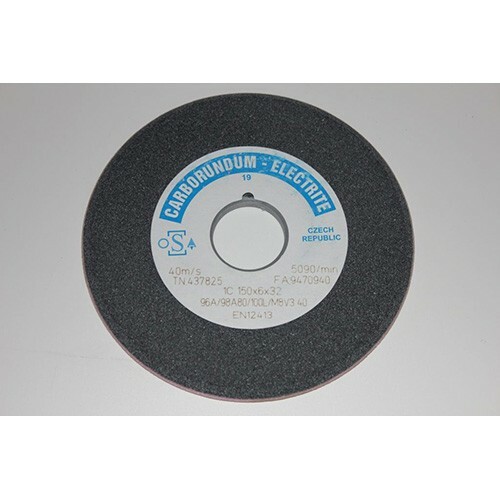

Dimensions and material of used grinding stones

Emery is a consumable material, but this does not prevent it from being one of the most important pieces of equipment. With regard to the working diameters of the circle, everything is simple - for standard, undemanding machines, it is 150 mm, for professional equipment, it varies depending on the complexity and volume of work. Also, craftsmen should not forget about the bore diameter - it depends on it what range of abrasives you can use with the purchased model.

Among the materials used in the production of abrasives, the following options are most popular:

| View | Scope of application | Appearance |

| Electrocorundum | Sharpening of carbon steels |  |

| Monocorundum | Working with high alloy alloys |  |

| Carborundum (Silicon Carbide) | Allows processing of cast iron and non-metallic materials |  |

| Diamond grit | Heavy Duty Metal Processing |  |

TOINFORMATION!

Also, such a parameter as structural density can play an important role. Discs with an index of 5-8 have a high density and are suitable for full sharpening. If the value is 9-16, you can only do small "cosmetic" procedures.

Machine weight

Many buyers, choosing modern sharpening equipment, do not pay tribute to such a significant characteristic as the weight of the product. And although at first glance it is insignificant, you will feel the whole “weight” of its importance when you come across time-consuming and large-sized tools. The fact is that only a unit with sufficient mass can cope with such situations - lightweight and compact solutions will simply fail. On the other hand, if you only sharpen knives, compact axes or garden shears, the heavy construction will only be a burden.

Which desktop grinding machine is better to buy in 2019: choosing the best models in the Russian market

The time has come to move from theory to real-life models of technology that is ready to effectively perform the functionality we have discussed above. So drum roll! Meet the ranking of the best grinders as of 2019.

Universal grinder Patriot BG150L

And here is the classic version, which, with a certain skill, can be used to sharpen almost any type of tool. The asynchronous design of the motor will save the owner from unnecessary noise, giving impressive performance. The presence of protective glasses and a lamp will preserve the health of the master and increase the accuracy of work. And the presence of two grinding wheels will make it possible to do several types of processing at once.

| Power, W. | Emery rotation speed, rpm | Grinding wheel diameter, mm. | Weight, kg |

| 150 | 2950 | 150 | 4,3 |

Tehno.guru editorial estimate: 9,2/10

Universal accessories DWT DS-150 KS

A better and faster result can be offered by this product. It cannot boast of having a lamp, but it is very reliable in operation and does not require specialized skills.

| Power, W. | Emery rotation speed, rpm | Grinding wheel diameter, mm. | Weight, kg |

| 150 | 2950 | 125 | 5,2 |

Tehno.guru editorial estimate: 9,4/10

Ryobi RBGL650G universal sharpener

At the top of our rating is a high-quality unit with a wide arsenal of functions. The most useful will be the presence of a sanding belt - this will maximize your possibilities and make the process interesting and not burdensome. The clear winner!

| Power, W. | Emery rotation speed, rpm | Grinding wheel diameter, mm. | Weight, kg |

| 250 | 2850 | 150 | 10,3 |

Tehno.guru editorial estimate: 9,8/10

Desktop machine for sharpening chains of electric and chainsaws Sturm BG60016

Chain link machines are quite specific and are not as popular as the versatile options. Nevertheless, the nominee we have chosen can make life much easier and save a substantial amount on the purchase of a new part instead of a blunt one. It is distinguished by impressive technical characteristics, combined with a reasonable price.

| Power, W. | Emery rotation speed, rpm | Grinding wheel diameter, mm. | Weight, kg |

| 160 | 3000 | 100 | 2,5 |

Tehno.guru editorial estimate: 8,8/10

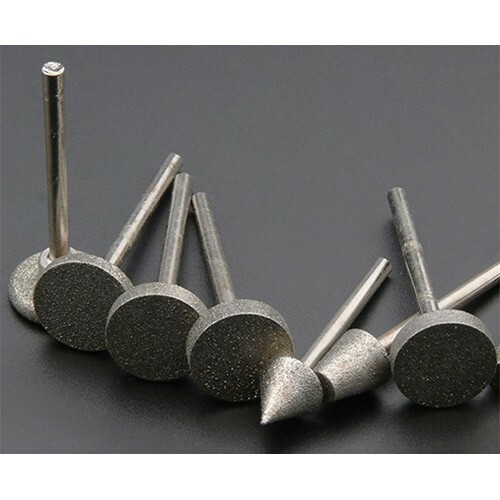

Grinding machine for drills Diold MZS-03

This practical and budgetary unit is simply designed to work with drills and knives. In addition to the democratic price, it differs in a design close to universal, as well as in the presence of a fairly wide set of nozzles.

| Power, W. | Emery rotation speed, rpm | Grinding wheel diameter, mm. | Weight, kg |

| 100 | 6700 | 48 | 1,1 |

Tehno.guru editorial estimate: 8,4/10

Electric knife sharpening machine Sorokin 20.100

But this candidate is already more solid - both an electric motor and decent performance indicators are available. This offer is suitable for a small workshop or other entry-level private business.

| Power, W. | Emery rotation speed, rpm | Grinding wheel diameter, mm. | Weight, kg |

| 70 | 140 | 118 | 4,3 |

Tehno.guru editorial estimate: 8,3/10

Desktop machine for sharpening knives and scissors Ganzo Touch Pro

And the first on our list is highly specialized equipment for household cutting tools. It cannot boast of having electrical components or high performance. But this is easily compensated for by the high accuracy of the work performed, an affordable price tag and the ability to return sharpness to any scissors or knives in a few minutes. And the presence of several abrasive stones in the kit will allow you to use different sharpening options.

Tehno.guru editorial estimate: 8,1 / 10

Is it worth buying equipment for sharpening cutting tools

Summing up the results of our entire small study, we can safely say that grinding machines will be relevant for more than a decade. You can, of course, simply replace the failed equipment and consumables, but it is much more practical and useful to economically use the available resources. Therefore, if you are fond of technology, work with cars or just work with a knife thrower, you should definitely have at least a simple sharpening machine at your disposal!