Many building materials used in the construction of residential buildings and outbuildings initially look unsightly, the erected walls require additional cladding. Facade decoration may still be required in case of loss of its attractiveness, with the formation of cracks. One of the best types of cladding is natural wood. With its help, you can perform not only external, but also interior decoration of the house with imitation of timber, clapboard, block house.

Content

- Finishing features

- Exterior decoration of the house with imitation of timber

- Advantages and disadvantages

- How to choose material

- Stages of installation of imitation of a bar outside

- Required materials and tools

- Vapor barrier

- Lathing

- Insulation installation

- Waterproof membrane

- Counter grill

- Installation of cladding

- Panel mounting methods

- How to dock correctly

- Surface treatment and care

- Combination of timber with a different finish

- Imitation of timber and plaster

- Imitation timber and stone

- Interior decoration of the house with imitation of timber

- Pros and cons

- Features and characteristics of the material for interior decoration

- Pine

- Cedar

- Larch

- Oak

- Maple and alder

- In which rooms can it be used

- Stylistic directions

- Interior colors

- How to fix the timber indoors

- Heat and vapor barrier

- Installation of the lathing

- Wall cladding

- Indoor treatment and care

- Varnishing

- Coating with different types of paints

- Textured paint

- How to calculate the amount of material

- Conclusion

Finishing features

Wood is a versatile material used in construction work for thousands of years. Due to its attractive appearance and a number of advantages, wood does not lose its relevance. Logs, beams and boards, glued and pressed wooden sheets (fiberboard, chipboard, plywood, etc.) are made from various species, which have a wide range of applications.

Houses built from timber look noble, but the cost of the structures is quite high. To save on construction costs, you can use lumber that mimics the surface of treated logs and glued boards. They can be used for cladding brick, concrete, cinder block, even wooden walls. They will not only decorate the base, but will also serve as additional protection against various influences.

False timber - edged board, the outer part of which is profiled under the timber. The panels are similar to lining, but they are wider and thicker. Thickness varies from 160 to 360 mm, width - 100 - 200 mm, length - 2000 - 6000 mm. Custom-made products may have other dimensions. To connect the elements together, a thorn-groove system is used, which allows you to make the final surface even, without cracks and defects.

For the production of finished products, conifers are most often used, such as spruce, pine, cedar, larch. Deciduous species such as oak, elm, maple, alder are much more expensive. Manufacturing technology consists of several stages: drying of blanks, sawing, processing antiseptic compounds, milling the surface with the formation of spikes and grooves, polishing, sorting products.

Imitation of a bar is used for interior and exterior decoration of buildings. Houses, garages, cafeterias, restaurants, and other structures intended for public or private use are decorated with cladding. The material allows you to completely hide the unsightly base. In terms of design, the raised beam has impressive potential. The cladding creates the illusion of classic wooden masonry, looks no worse than the original.

Exterior decoration of the house with imitation of timber

You can decorate the exterior of your own home in different ways. For work, wet building mixtures or dry finishing materials are used. When choosing a suitable raw material for cladding, first of all, attention should be paid to its vapor permeability. Exterior finishes must conduct steam better than the building material used to build the walls.

Only wood meets the requirement. This is the only type of cladding that removes excess moisture without any problems. The cheapest covering can be organized using a regular planed board, but a false beam allows you to make a better design. It can sheathe any surface. The main difficulty lies in attaching the battens to the facade of the building.

For work, only cedar, larch, oak and ash are used. These breeds have the highest resistance to decay. Spruce, aspen, alder, linden, and other species with a low ability to withstand factors and agents of destruction are not suitable for outdoor use.

It should be borne in mind that the thickness of the lamella should be more than 25 mm, and the width - 150 mm, otherwise the masonry will not look like natural beams, but like a standard lining, laminate.

Advantages and disadvantages

False timber surpasses any other siding in terms of decorative characteristics, even imitating the texture of a tree. First, the material is natural wood. Secondly, its outer surface exactly matches the profiled bar. However, an attractive appearance is an important, but not the only advantage of cladding. Among the main advantages are:

- Environmental friendliness. The lumber is completely environmentally friendly. It does not emit harmful substances, it is absolutely safe for humans.

- Simple installation. You can install the panels yourself. To do this, you need to have an idea of the order of work, the presence of minimal construction skills.

- Sheet pile connection system. Due to the presence of spikes and grooves, the lamellas are securely fastened to each other, and ventilation of the entire structure is carried out through the grooves on the back side of the panels.

- Low cost. Finished products are not much more expensive compared to artificial turf, and the installation price for all types of siding is almost the same.

- High aesthetics. The facade clad with building materials looks neat, expensive and noble, and only a professional can distinguish it from real masonry.

- Protective function. The cladding protects the walls from mechanical stress, sunlight, and natural phenomena.

- Long service life. With proper installation work, timely maintenance, the coating will last for a long time.

- Thermal insulation and noise reduction. The cladding increases the heat-insulating and sound-insulating properties of the enclosing structures.

- A light weight. Thanks to this, it is possible to perform cladding of almost any partitions.

Like any other material, the raised beam is not without its drawbacks. The most critical disadvantages include:

- Low fire resistance. Lamellas quickly ignite, even processing with special compositions of the finishing surface does not allow this parameter to be nullified.

- Periodic care. It is necessary regularly, at intervals of 2-3 years, to change the paint and varnish layer, to treat the surface with antiseptic and other means that protect the wood from precipitation, decay, and pests.

- The price of accessories. Unlike imitation of timber, the cost of additional elements (for example, external or internal corners, decor, window framing) is very high.

How to choose material

Panels imitating timber are presented in a wide variety on the market. They differ from each other in many ways, on which the cost of the products depends. To save money, it is best to buy siding directly from the manufacturer, but not always there is such an opportunity, and most companies most often sell only large batches of ready-made products.

At first glance, it is not difficult to choose an imitation of timber for outdoor decoration, but it is not so. It is necessary to understand the peculiarities of the building material, which will allow not only to save on the purchase, but also to purchase a quality product that will last more than one year. If there is no professional knowledge in the field of construction, you should heed some of the recommendations of experts:

- Initially, you need to decide on the size of the board. This indicator should correspond to the parameters of a real bar, it depends on the type and purpose of the structure. So, the width of the panel is: for outbuildings - 100 mm; for country houses - 120 - 150 mm; for buildings intended for permanent year-round residence - 200 mm. It is best not to make connections on the façade, so long 6000 mm lamellas should be chosen. If the length of the product is not enough, then the joints can be masked using decorative strips.

- The next step is to take measurements. It is necessary to calculate the total area of the structure, excluding window and door openings. On the basis of this, the calculation of the amount of false beam is made, with a small margin.

- In order for the cladding to serve for a long time, you should opt for such types of wood as oak, larch, ash. You should not save by buying cheaper options, it is better to overpay for quality once and enjoy the result for more than one year.

- The variety is of great importance. The entire profile is sorted into classes: Extra, A, B, C. The first of these is the most expensive, very rare on sale. The most popular type is A, it is characterized by the absence of defects. Some people like the third option, as specks and cracks give the finish a more natural look.

- The moisture index affects the preservation of the original appearance. Exceeding 15% of the threshold threatens with the fact that during operation the building material can warp and lead.

- A visual inspection of the product is required immediately prior to purchase. The surface of the products must be flat, protruding or fallen out knots, mechanical damage, rotting, insects are inadmissible. The elements of the tongue-and-groove connection system must be complete.

- The whole batch must have the same shade.

- Particular attention should be paid to accessories and decorative elements, on which the overall appearance of the cladding depends.

Stages of installation of imitation of a bar outside

If you have the skills to carry out repair and construction work, you can finish the facade of the house yourself. The main thing is to comply with the technology. False beams can be used to sheathe wooden, concrete, brick, foam, gas, cinder block walls. The installation of the material is carried out in several stages, namely:

- preparation of the foundation;

- fastening the vapor barrier;

- installation of the lathing;

- laying insulation;

- counter-lattice stuffing;

- installation of lamellas;

- final surface treatment.

Regardless of what building material the building is erected from, the preparation of the base is carried out in the same way. Plaster is removed from the walls, mortar residues (if any) are removed, they are cleaned of dirt and dust. If necessary, the gaps are closed, the partitions are covered with a primer.

Required materials and tools

The installation technology for all types of siding is almost identical, the false beam is no exception. A slight difference is only in the materials and tools used for their processing and installation. To complete the work you will need:

- hammer, pliers;

- hacksaw for metal, cross-cut saw, circular power saw;

- pencil, tape measure, construction square, level, nylon threads or fishing line, plumb line;

- screwdriver, cutter knife, goggles;

- screwdriver, drill, grinder;

- beams, slats or metal profiles to form lathing and counter-lathing;

- vapor barrier, insulation;

- imitation of timber, auxiliary elements and decor;

- antiseptic impregnations, varnishes, paints;

- dowels, nails, screws, etc.

Vapor barrier

Some owners who decide to insulate their home on their own want to save on expensive film protection, not fully understanding its purpose. However, according to the approved standards, a vapor barrier is indispensable. Polymer varnishes, a layer of roll or sheet materials protect thermal insulation and building structures from steam penetration, and, consequently, from condensate precipitation and absorption.

Installation of a vapor barrier layer is carried out after preparation of the base, removal of dirt from the surface, treatment of wood, impregnation of it with antiseptics. For work, you can use special mastic, films with aluminum foil, membranes, for example, the brands "Izospan", "Megaizol", and others. Rolls are rolled from bottom to top, the canvas is attached to the partition using wooden slats, staples, in another way.

Laying of films or membranes is carried out with an overlap. Punctures, cuts, and other damage must be sealed with mounting tape. The tightness of the canvas to the wall does not matter, after installation it will be pressed against the crate. The place of moisture condensation (dew point) is also taken into account. The type and thickness of the insulation depends on this parameter, the thicker it is, the less the risk of steam transformation into water in the material of the partition.

Lathing

It is almost impossible to finish the house with a false beam without lathing. The frame plays an important role in the entire structure. Firstly, it allows the exterior walls to be leveled. Secondly, it makes it possible to lay insulation under the siding. Thirdly, it provides ventilation, which prevents condensation from forming. Fourth, it distributes the load evenly over the entire partition.

The main load-bearing elements are beams. Before fixing, all wooden parts are treated with antiseptics and fire retardants. Installation work begins with marking. With the help of a level, a plumb line and a nylon thread, marks are set. If the wall is uneven, then to install the frame, you will have to use pads or underlays so that the outer edges of the sheathing form a single flat vertical plane.

To determine the distance at which the bearing beams will be spaced from the base, it is necessary to find the most protruding or highest point on the entire surface, it will serve as a level. First of all, the extreme structural elements are installed, the distance between the remaining bars depends on the width of the insulation. To fasten the board to concrete, brick, cinder block, dowels are used, to wood - nails and self-tapping screws.

Insulation installation

The main types of insulation used for exterior wall decoration are expanded polystyrene, polystyrene foam, polyurethane foam, mineral wool, ecowool, glass wool, and others. When choosing a specific type of thermal insulation, certain indicators are taken into account, both of thermal insulation materials and the raw materials used for the construction of partitions. These characteristics include thermal conductivity and vapor permeability.

The method of insulation directly depends on what building material the walls are erected from. For example, for houses built of wood, aerated concrete, gas silicate, large-porous expanded clay concrete, it is beneficial to use breathable mineral wool slabs. For brick buildings, penoplex, expanded polystyrene, characterized by the lowest coefficient of thermal conductivity, are suitable.

The fastening method depends on the type of heat-insulating material. Soft options are stacked directly into the crate, between the supporting elements, the distance between which corresponds to the width of the product. They are additionally fastened with dowel-nails. The foam shrinks onto the glue. However, adhesives are rarely used independently; for reliable fixation, dowel-umbrellas are additionally used.

Waterproof membrane

Depending on the vapor permeability of the wall, the first layer of vapor barrier may be present (vapor-permeable) or absent (vapor-permeable) in the overall cake of the ventilated facade. A superdiffusion membrane is always used. It is installed immediately after the insulation, and serves to move the dew point outside the heat-insulating layer into the ventilation gap, from where the condensate is removed naturally.

The wind-moisture protective film not only removes steam, but also protects the insulation from street moisture. For work, you can use Izospan A, other materials with similar properties. The canvases begin to be fastened from the floor, laid horizontally. Each next layer is overlapped, that is, it closes the top of the previous one with its lower part.

It is necessary to work very carefully. It is impossible to overtighten the canvas in order to prevent breaks and other damage. Fastening to the lathing is carried out with staples using an industrial stapler. The joints are additionally glued with tape. To find out which side the strip should be attached to, you will need to read the instructions. This moment is very important, the direction of moisture removal depends on it.

Counter grill

The next step after laying the hydro-barrier will be the installation of a counter-grill. For its organization, beams are used with a thickness of 20 to 50 mm, a width of 30 to 50 mm. The choice of dimensions depends on the total area of the wall, the larger it is, the larger the lumber. The step and direction of the elements completely coincides with the similar parameters of the rafters, since the slats are packed on top of them.

The counter grill serves several useful functions. Firstly, it prevents the false beam from tightly fitting to the superdiffusion membrane. Secondly, it provides ventilation, respectively, helps to remove excess moisture that forms on the surface of the film. Thirdly, it acts as an additional clamping element, provides reliable fixation of waterproofing.

Some builders neglect the norms and do not install the second crate, referring to the fact that there are special ventilation recesses on the back of the finishing material. Thus, they violate the technology of forming a ventilated facade, which, as a result, can lead to deformation of the finish coating. The existing grooves do not provide adequate ventilation.

Installation of cladding

After assembling the frame, laying steam, heat, waterproofing, installing a counter lattice, you can proceed to the finishing. It is performed in the following sequence:

- Using a laser level or nylon thread above the upper edge of the base, a horizontal straight line is struck along the entire perimeter of the structure.

- At the marked level, the first row of lamellas is fixed, which are installed with a thorn down. In this case, the board is nailed, screwed along the entire length from above and below.

- The second and subsequent panels are inserted with a spike into the groove of the previous strip, and fasteners are carried out only in the upper part.

- A board that is installed on top often does not fit in width, therefore, to get the right size, it is dismissed along the length.

- The slats are attached to the counter lattice with a small technological gap. Under the influence of natural factors (change in temperature, air humidity), wood can increase and decrease in size, with rigid fixation it can lead.

Panel mounting methods

There are three ways to fix the slats to the crate: wood screws, special nails, clamps. The first option allows quick installation. However, it is worth considering the peculiarities of wood. To ensure that the strips do not crack when installing, it is necessary to drill a hole for each screw, which will correspond in diameter to the fastening.

The main disadvantage of self-tapping screws is the rigid fixation of the imitation of the timber to the crate. Increases in temperature or changes in moisture stress the wood, and the lack of movement can cause serious damage to the material. Nails can solve this problem. Special types with anti-corrosion galvanizing should be used. However, certain skills are required to work with them.

Kleimers are the best choice. They do not leave marks on the surface of the board, which must be masked with a putty or PVA glue. The slats are not rigidly fixed. However, additional costs will be required to purchase them. Installing the brackets is pretty straightforward. On the one hand, they grip the panel, on the other they are attracted to the guide rail on the frame.

How to dock correctly

Docking of elements can occur in the corners and along the length. Each species has its own camouflage methods. In the first case, the problem can be solved by three methods:

- The adjoining edges of the planks are sawn from the inside at an angle of 45 degrees. When two bars are joined, they will form a right angle. Such a connection looks neat, not striking. However, the fit must be perfect. This requires accurate calculations, high professional skills, otherwise gaps will be visible.

- You can close the connection using a decorative corner strip, which is purchased with the finishing material. This is the most acceptable option.

- Shoot down two planed boards with the letter G.

Lengthwise joining of elements can also be hidden using three different approaches:

- The simplest method is to fit the panels joint to joint. It will be possible to do this only when the installation work has been done very well, and there is no displacement of the rows along the entire wall. After painting, the contact points of the panels become invisible.

- Using a special decorative strip.

- Saw the boards at the joint at an angle of 45 degrees. In contrast to the previously considered option, in this case it is necessary that one lamella is found on another, forming a single whole with it, which also requires special accuracy.

Surface treatment and care

All problems that arise with the raised beam are due to the natural properties of the wood. Among the main reasons that can lead to the appearance of defects are:

- fungus and mold;

- harmful insects;

- ultraviolet radiation;

- humidity;

- uneven evaporation.

The listed problems are typical for any lumber, therefore, the methods of dealing with them are identical. The first thing to do is to treat the panels with an antiseptic solution. However, new materials on the market usually already have this protection, but additional the coating will not damage, in this case you can be sure that the wood will be protected from decay and insects.

Ten days after applying the antiseptic, you can treat the lamellas with fire retardants, which are applied in 2-3 layers. They will provide fire protection. After that, the material is primed, which saves paints and varnishes. At the final stage, the surface is coated with varnish, wax or paint in several layers. With the right choice of coverage, its renewal will be required in 3 - 6 years.

Combination of timber with a different finish

Building a house, like repairing it, is a complex and very costly process that requires a special approach. Any owner wants to make his home unique, while using only natural raw materials that will not harm health. All these qualities are possessed by natural wood of different species. However, achieving the individuality of the project is problematic.

The residential building design industry is constantly evolving. On the basis of innovative technologies, designers bring creative ideas to life. They make combined facades, using materials that are incompatible at first glance. For example, drawings are applied to plastered surfaces, in the Art Nouveau style, different types of siding are installed on one wall, which imitates brick, stone, wood, and other actions are performed.

By and large, any house in the decoration of which two or more types of building materials are used is combined. These buildings are attractive and respectable. They look advantageous against the background of other structures. However, along with various design fantasies, there is also a strict classics that carries rationality and experience developed over the centuries.

Imitation of timber and plaster

The first mentions of the use of combined materials in the construction of residential buildings date back to the 15th century. Half-timbered buildings were built in Eastern Europe and Scandinavia. At the same time, Alpine shepherds living in the rugged mountainous terrain built their homes of stone and wood. It is the Alps that are the birthplace of chalet-style houses. Their main difference from their early counterparts is their low and sloping roof.

The heyday of the construction of these buildings fell on the 16-17 centuries. At the same time, the external finishing of the first floor was made of limestone, and the upper tiers, erected from massive pine beams, were left without cladding. After studying the history, you can understand where the ideas for using various building materials came from. It should be borne in mind that combined houses and combined facades are completely different concepts.

You can use cladding on any walls. And if earlier lime mortar was used for plastering, now there is a wide variety of this material, which can be used to cover wooden, brick, cinder block, aerated concrete, other partitions. There are a lot of combination options. Plaster can be applied only to the columns, or the basement, the corners of the building, and decorate the rest of the space with a false beam.

Imitation timber and stone

The choice of raw materials for the construction of a combined house is very large. If the first floor was built of torn stones or a savage, then its facing can be omitted at all. However, if this building material does not meet the wishes and requirements, then brick can be used. It is worth abandoning the foam block, since a strong foundation is required to ensure a reliable interfloor ligament. Aerated concrete is quite fragile.

Wood and natural stone go well together. Owners of two-story houses with the help of finishing materials will be able to create the classic look of a combined building. To do this, the first floor can be sheathed with siding for masonry, and the second with a false beam. It does not matter what building material was used in the construction, be it wood, gas silicate, aerated concrete or monolith.

Single-storey structures are also suitable for the use of different materials. It all depends on the design of the housing itself. So, the side partitions can be faced with natural masonry, and the front surface - with a false beam. There are options when different imitations change each other on the same facade in turn. The choice of a particular type of design depends solely on the personal preferences of the home owner.

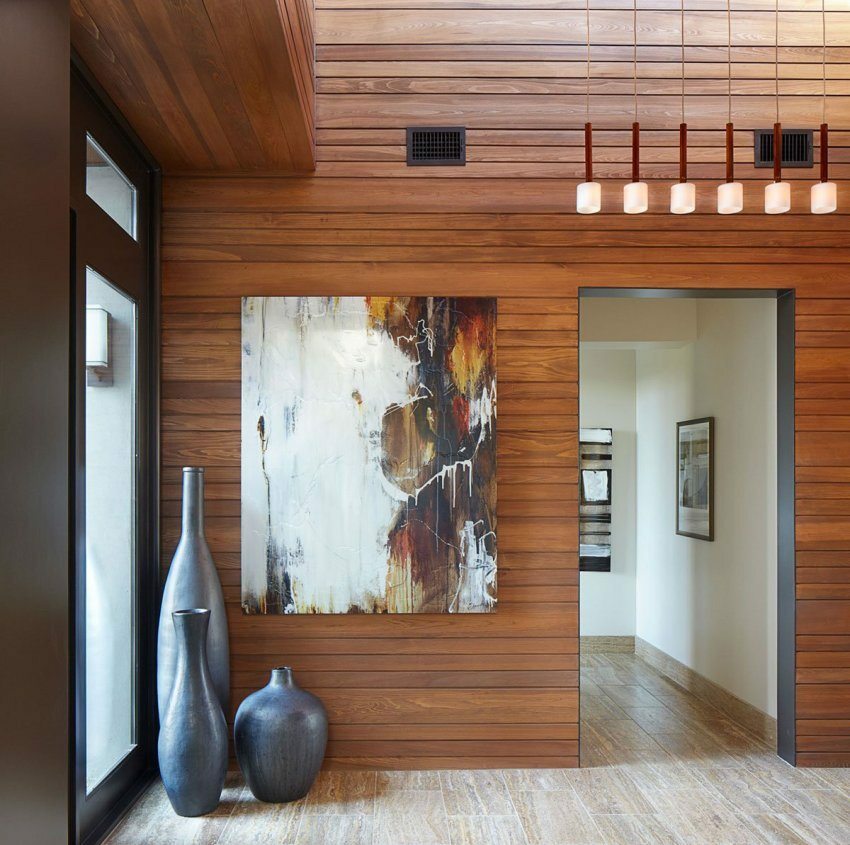

Interior decoration of the house with imitation of timber

False beams are most often used for external decoration of private houses and cottages. This is due to the properties and method of fastening the material. It has a fairly large width and thickness; to install it, a crate is required. It not only visually reduces the internal space, but actually eats up the usable area. However, this type of finish should not be neglected.

The building material is made from different types of wood, therefore it meets all the requirements of environmental friendliness. It creates the impression that the building was built from a solid processed timber with a magnificent texture, provides a healthy atmosphere, increases the comfort and coziness of living. There are several methods for decorating a space with wood panels:

- Monolithic. With the help of lamellas, the entire area of the walls or ceiling of the room is completely sheathed, as well as the option with facing absolutely all surfaces.

- Combined. Different raw materials are used for cladding. The partition is only partially covered with wood, on it the beams are combined with stone, wallpaper, paint, glass panels, and other materials.

Pros and cons

Interior decoration made of wood creates a cozy atmosphere in the house. In this case, it is not necessary to sheathe all surfaces with an imitation of a bar, in some cases it is enough accent wall or decorate a specific area to create a beautiful home island hearth. Despite some of the disadvantages created by the inconvenience, the material is popular. This is due to its positive properties, namely:

- false beam allows you to create an original interior;

- each element has a unique texture;

- wood is characterized by good steam, heat and sound insulation;

- imitation of a bar creates and maintains a natural microclimate in the room;

- lamellas are inexpensive in comparison with other types used for cladding;

- it is an environmentally friendly product;

- it is easy to work with the material, the installation can be done by hand;

- it can be used to make a flat surface, level the walls;

- with proper processing and care, the cladding will last long enough;

- wood is suitable for many styles.

Wooden beams are not devoid of some disadvantages:

- panels reduce the usable space, so in small rooms this type of finish will have to be abandoned;

- weak resistance to fire, even fire retardants do not save;

- the coating requires periodic maintenance, renewal of the protective layer.

Features and characteristics of the material for interior decoration

Inside the house, wood is not exposed to negative environmental influences, therefore, the requirements for some characteristics of the product are reduced. At the same time, the false beam must have high aesthetic qualities. Please note that wide panels should not be used for interior work. This indicator should be in the range of 100 - 140 mm, the thickness can be any, usually it does not exceed 20 mm.

The use of a narrower board in interior decoration is due to the fact that it visually allows you to increase the ceiling, creates the impression that the structure is folded from the crowns of a solid bar. Wide panels can ruin everything; in a small room, the cladding will generally merge into a single mass. To decorate the walls, you can choose different types of wood, which differ in texture, price, and have individual properties.

Pine

Needles are always relevant in construction. This is the most common type of timber imitation, since the cost of the material is minimal in comparison with other breeds. Pine is more in demand than spruce, which has many knots. The main disadvantage is the high resin content, so it is not recommended to use coniferous panels in rooms with high temperature conditions. Suitable for cladding corridors, kitchens, balconies.

The wood is durable, soft and lightweight. After drying, it practically does not warp. The color of the sapwood can vary from pale yellow to reddish, the kernel - from pinkish to brownish red. The building material has a tendency to yellowing, which appears after a certain time. Despite the high natural resin content, the tree is prone to rotting, which imposes restrictions on the operating conditions.

Cedar

Wood is one of the most expensive timber imitation. The cedar finish is very prestigious, wealthy people can afford it. This is due to the fact that the breed grows only in untouched nature, as soon as a person gets there, the trees disappear. However, do not confuse real cedar with Siberian cedar, which is just a special kind of pine with good decorative characteristics.

Substances released by wood have disinfecting properties. The material constantly cleans the air in the room, which allows it to be used in the nursery and in the bedroom. The tree has a noble pattern that will add originality to any interior. Due to the complexity of processing, lamellas are rarely found on sale. Many companies make cedar false beams only to order.

Larch

In terms of strength and resistance to decay, the breed surpasses many coniferous types of wood. In terms of its characteristics and various solutions, it is comparable to oak, but has a lower cost. In industrial production, Siberian larch is used, less often Kuril and European larch. Distinctive features - high density, resistance to various influences, including the environment.

The material allows you to create an original design, gives the interior nobility and high cost. It can be used to decorate a bathroom, kitchen, loggia, balcony, and other premises. Imitation of a bar is suitable for both indoor and outdoor work. Wood has a specific smell. The breed is recommended for people suffering from respiratory diseases.

Oak

The wood has an expressive structure and beautiful color, but it is quite expensive. The kernel can have a different color - from light brown to dark brown. The material is characterized by high strength, it bends well without breaking the fibers. Due to the presence of tannins, it has the highest resistance to decay in comparison with all deciduous species.

The most valuable and expensive lumber for finishing is bog oak. After a long stay in water, it acquires high strength, black color. Like larch, it is used for external and internal work. Logs are very difficult to handle. This is perhaps the best type of wood that is suitable for absolutely all premises. It can be used to decorate a living room, an entrance hall, a kitchen, a nursery, a bathroom, an office, even a bathhouse and a sauna.

Maple and alder

The natural color of alder varies from white to pale brown, but after the felling it changes its color to reddish brown. The material is characterized by low strength, during the drying process it jars. The main advantages lie in the physical properties of wood. It allows you to create an imitation of mahogany and ebony, is odorless, resistant to the absorption of foreign aromas.

Maple, like alder, is intended for internal use only, since both species are characterized by very low resistance to decay. Therefore, they can only be used in dry rooms where people live all year round. The wood has a reddish tint, which becomes more yellow over time. The texture is uniform. Heart-shaped rays give the finished product a special charm.

In which rooms can it be used

Imitation of a bar is used for walls and ceilings. It is a textured living material that has a number of advantages. It allows you to create the feeling of a wooden house in the interior of one or all rooms. Wood allows the coating to breathe, some varieties generally purify the air. With the help of cladding, you can create a unique design, emphasize a certain style.

False beams are used in the design of the interior space of apartments, country estates, private cottages. It will perfectly complement the corridor, living room, bedroom, nursery, office. Some breeds can be used in the bathroom, kitchen, balcony, loggia. In general, the material is versatile, compatible with absolutely any room. However, it should be borne in mind that the finish actually reduces the usable area.

In the kitchen, using imitation timber, you can sheathe both walls and a kitchen backsplash, but additional wood processing will be required. Different colors will allow you to emphasize the severity or warmth of the space. In the living room, it is enough to make one accent surface, or arrange a certain area, you can completely cover all the partitions. It all depends on the preferences of the owners, the style.

Stylistic directions

Wood is ubiquitous, it has long been used in construction. This material is respected in all cultures. Therefore, natural wood trim is compatible with almost any interior style, from country to high-tech. However, the most related areas are eco, rustic, provence. Here, a wooden wall can become the main accent of the room.

False beam will look good in a classic interior. The color palette of the classics includes three main shades: beige, cream, brown. It is not difficult to select the appropriate panels. For a Scandinavian design, the boards will have to be painted with white paint. For country and ethno in texture and color, oak is best suited, which has a pronounced woody pattern.

Whitewashed and aged panels made of oak, ash, pine are appropriate for rustic and other ethnic styles. For a loft style, it is enough to decorate only the ceiling with lamellas or decorate a specific area. Chalet style is suitable for a country residence. There must be animal skins on the floor and walls. Hi-tech implies the use of wood material only as an addition.

Interior colors

To preserve the natural texture and color of wood, when processing panels, preference should be given to impregnations, colorless varnishes, wax. It is better to refuse paint. In this case, the color of the board will directly depend on the type of wood. The most common shades are light brown, brownish red, coffee. There are also unusual ones, for example, blue, green, pink. For clarity, consider some options (variety - colors):

- oak - from light brown to dark brown;

- beech - white with a yellowish-red tint;

- ash - from dark brown to light yellow;

- alder - red-brown;

- walnut - light brown to black;

- pine - from pale yellow to reddish yellow;

- larch - from light yellowish to reddish;

- yew - yellowish white.

How to fix the timber indoors

Indoor timber trim is chosen for many reasons. First of all, it is an environmentally friendly, natural material, ideal in all respects for the interior design of living quarters. In such a room there will always be a feeling of comfort and unity with nature. In addition to the aesthetic benefits, the lumber finish stands out for its good strength, durability and excellent sound insulation. Installation of wooden panels is easy to do with your own hands.

Heat and vapor barrier

A special film is attached only to the prepared surface. This will prevent the formation of condensate moisture inside the casing. To do this, use a stapler, if it is necessary to fasten it to a wooden surface, or a crate of beams, if the base is made of concrete or brick.

The seams of the film must be overlapped and secured with tape. This will prevent rupture of the membrane during the installation of the battens and thermal insulation.

If there is no external thermal insulation of the house, it is necessary to lay insulation inside. Block, roll material is tightly laid between the guiding elements of the sheathing. It is important to exclude the formation of gaps and docking holes.

Installation of the lathing

For a wooden base, the crate is made from bars with a cross section of 50 mm. The workpieces are well dried, treated with various agents and antiseptics to increase moisture resistance. On concrete or brick walls, the crate is made of a metal profile.

First, the guides are fastened vertically with a step of 800 mm. Then the corner elements are mounted. In the places where shelves and other devices are attached that can make the structure heavier, additional bars are installed. The wiring is pulled between the crate using a corrugated protection.

Wall cladding

When the thermal insulation is installed and the lathing is installed, you can start laying the panels under the timber. The technology provides for a clear implementation of the instructions step by step:

- The first panel is mounted at a distance of 50 mm from the corner, then the entire row is built.

- Boards are installed only upside down with thorns.

- The gap between the panels should be 3 mm, taking into account the thermal expansion.

- It is important to constantly control the verticality of the cuts, especially when decorating windows, corners and openings.

- The panels are mounted strictly from bottom to top.

- When the main panels are installed, proceed to the installation of transitions between the planes using skirting boards.

Indoor treatment and care

Natural material has some features that require special care for it indoors. The negative factors are susceptibility to wetting and swelling, to the effects of various microorganisms. It is possible to exclude the deformation of the timber beam with the help of regular processing with special means.

Varnishing

Water-based varnishes are well suited for processing wooden lining. They do not exude absolutely no smell, dry quickly, do not contain organic solvents. Water-repellent scuba diving equipment is also often used. The impregnation repels water and provides reliable protection against decay.

Thanks to a thin transparent film, varnishes allow you to preserve the natural color of wood. To give additional strength, polyurethane compounds are used. You can apply this coating with a brush or swab.

Coating with different types of paints

The main feature of this type of protection is the ability of the mixtures to completely hide the surface of the tree and give it a certain color. The following types of topcoats are suitable for indoor beams:

- Alkyd enamels. They have a pungent odor, emit toxic substances, and form a dense film on the surface.

- Water-dispersive paints. Completely ecological compounds, dry quickly and are quite durable.

- Polyurethane enamels. Toxic in liquid form, but resistant to mechanical damage.

Textured paint

The surface relief can be created with a wooden brush. The object is led along the grain of the wood and destroys the soft components. The excess is removed and varnish or paint is applied. The effect of bleached wood is created in a similar way, but white glaze is added to the coloring composition.

Artificial aging works are performed mechanically. Deliberately damage the surface in several places, trying to do this as naturally as possible. Then it is painted according to the standard.

How to calculate the amount of material

When determining the cubic capacity of lumber, it is necessary to take into account that their section cannot be a full-fledged rectangle or square. Therefore, the calculations will be approximate.

First of all, you need to determine the parameters of the board. All calculations are performed in meters. Then the surface area is determined using a simple formula and a suitable set of materials is selected according to the parameters. You can also use an online calculator to calculate the amount of materials.

Conclusion

Timber imitation is a versatile building material. It is made from various types of natural wood, keeping all the advantages and disadvantages of natural raw materials. Compatible with many styles. It can be used for decoration and interior and exterior. The panels are exactly the same as the profiled beams. It is easy to work with them, if you have skills in construction, you can do the installation yourself using a training video, photo.