When organizing a home garden in a suburban area in order to obtain a harvest of vegetable crops, you should take care of aesthetics. Prefabricated beds are made from a variety of materials. One of them is a galvanized metal profile with a moisture-resistant polymer coating. Hot-dip galvanizing protects the metal from corrosion, and the polymer ensures the preservation of the anti-corrosion film, gives the rolled metal a decorative look, does not allow the earth to crumble, and keeps moisture from evaporation.

Smooth beds with neat sides are the dream of any gardener

Various root crops are grown in high beds. It is easier to care for the plants, the load on the back muscles and the spine is reduced. When sowing, weeding, loosening, harvesting, working on a fenced garden bed is easier.

Garden beds with fences do not crumble, which is important for areas with loose sandy or sandy loam soil

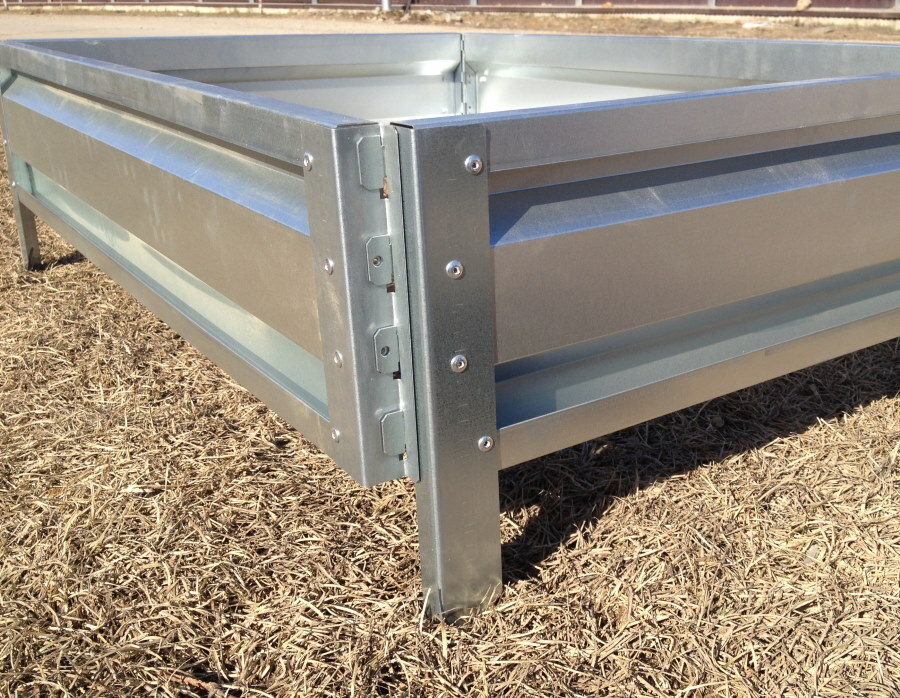

The sides are increased to the required height. Manufacturers offer ready-made, easy-to-install kits for metal fences. Prefabricated beds are easy to do with your own hands, with a minimum set of tools. The side walls are held together using special metal clips. Kits are available for sectional designs. The transverse profile adds extra rigidity, helping to create a clear boundary between the crops being grown. Galvanizing is designed for long-term operation, fences do not rot, pathogenic microorganisms do not develop on the coating.

Serious mistakes gardeners make when choosing and working with metal beds

Content

- Serious mistakes gardeners make when choosing and working with metal beds

- Pros and cons of using galvanized metal fences

- Type of finished beds made of metal with a polymer coating

- Video: Practical experience of using metal beds

- Photo of metal beds with a polymer coating

For the correct organization of the garden, it is important to approach the choice of material for the fences. Experts advise to measure the strength of the profile with the height of the metal beds.

High-quality polymer-coated beds not only look attractive, but also last a long time

Hot-dip galvanizing technology provides for the creation of a uniform molecular film of metal over the entire surface of the rolled product. Zinc electroplating is not so durable, there may be sagging and discontinuities.

Metal selection criteria:

- When buying a protective polymer profile, it is better to choose metal with a hot-dip galvanized layer of at least 25 microns. With a smaller layer, there is a high probability of corrosion damage with minor defects in polymer spraying.

- The thickness of the rolled products is commensurate with the height of the structure. For low beds (from 15 to 25 cm), a wall thickness of 0.35 to 0.8 mm is sufficient. The best option is steel 0.5 mm. For tall structures, it is better to choose a more reliable profile, with a wall from 0.8 to 1 mm. The mobility of the frame depends on the thickness of the metal. Despite being filled with earth, the soft profile will “play” in the spring during the thawing of the fertile layer.

- When choosing a color, it is important to take into account the thermophilicity of crops. Cucumbers, zucchini, pumpkins love when the ground warms up well. Carrots, potatoes need medium temperatures, at high temperatures, the growth of root crops slows down, the earth dries faster. Garden beds with dark fences will need to be watered more frequently.

- Ready-made kits for metal beds have everything you need, the format corresponds to film shelters. During rains, nighttime cold snaps, it is easy to build a greenhouse.

You cannot replace the special profile for the beds with cut roofing iron that is not designed for lateral loading. The destruction of the beds is possible, the risk of injury increases.

More often he makes metal structures for vegetable crops. Flower beds fenced with a ready-made profile look no less presentable. The sets are used to form front gardens, children's sandboxes and much more. You can fence off a recreation or barbecue area, isolate a footpath, use a profile for supporting walls when planning terraced slopes.

From metal borders, you can assemble a bed of any length and different shape, you just need to purchase the necessary additional elements

To assemble the finished forms, you only need a screwdriver and a hammer. It is a mistake to assemble in advance, without planning the territory. Possible alterations significantly weaken the structure. Pre-markings are made, irrigation and drainage systems are mounted. When assembling, the corner and intermediate support pins are first deepened. The burial depth depends on the density of the soil. The pins are extended with inserts.

Typical design bed assembly diagram

A standard fence is assembled within 30-40 minutes, depending on the format. The kit includes assembly instructions with drawings.

Most often, the beds flew are assembled among themselves using self-tapping screws or bolts

Recently, there have been models with more convenient snap fastening (French systems)

French systems are the most convenient. Thanks to the fasteners, made in the form of tight-fitting latches, assembly time is cut in half. Variants are available with special edging.

Pros and cons of using galvanized metal fences

It is noticed that in high beds the yield of garden crops increases by a third, root crops grow even, without damage. The risk of fungal diseases is reduced, the polymer-coated metal protects crops from damage by slugs and rodents.

Polymer-coated beds are available in a wide range of colors

Collapsible beds have high functionality, the capacity can be used as a regular bed and greenhouse. If desired, plant residues or manure are placed on the bottom of the fenced container.

Another option for using the finished structure is a compost bin. Additionally, you can alternate compost with a layer of earth, mineral fertilizers. It turns out high-quality soil for growing seedlings.

Polymer beds can be easily transformed into mini-greenhouses, in which you can grow tomatoes, eggplants, nightshades, get an early harvest of potatoes, vegetable crops. Bulk options are especially relevant for growing melons and gourds with a high occurrence of groundwater.

Metal beds can be used both outdoors and in greenhouse conditions

During feeding, fertilizers with effluents do not fall on the paths, do not feed perennial weeds. Greens can be mowed, uprooted, spilled with pesticides, without fear of damaging the beds.

Now about the aesthetic side of the issue. The earth falling from the side surfaces of the unformed ridges from dew and rains turns into sticky mud, which gets onto the garden paths with shoes. We often have to do the cleaning. Colored beds and polymer-coated metal are free from this disadvantage. Plant care becomes enjoyable.

Raised beds solve the problem of infertile or stony soil - such a bed can be installed anywhere and fill the box with good soil

There are practically no downsides to polymer metal beds. When choosing high-quality products, the structures serve for a long time.

Type of finished beds made of metal with a polymer coating

Manufacturers produce various options for metal structures. The main parameters for making a choice:

- metal thickness, for polymer-coated beds, rolled products with a thickness of 0.35 mm to 1 mm are used;

- thickness and type of galvanizing, minimum layer thickness 25 microns;

- type of polymer coating;

- the presence of stiffeners, the figured profile is less susceptible to deformation during seasonal ground movements, it is recommended to choose options with a central type of load placement;

- the height of the panels.

Beds without stiffeners are the most inexpensive, but they may not withstand the load even with a low side height

Beds with profiled walls are more reliable and have a higher side height

Standard dimensions of tall metal beds:

- height 15-18, 35 cm;

- width 5–65 cm;

- minimum length 1.95 m.

Manufacturers also adhere to other standard sizes: 175x1000x4000 mm with a wall thickness of 0.5 mm, excluding the polymer coating.

The structures must be reliable and durable. When erecting fences above 35 cm, it is necessary to use a more durable metal that will not deform under a snow load (up to 1.5 mm).

A protective polymer coating approximately doubles the service life of a metal bed

Polymer spraying performs two functions at once: decorative and protective, protects the protective layer from damage. The modern profile is made using two technologies:

- The polyester layer is resistant to ultraviolet light, high humidity, the profile is recommended for open and protected ground, but inferior to its analog in decorativeness;

- Printech is a coating that imitates the texture of natural building materials, thanks to a passivating layer, it withstands contact with aggressive reagents.

Ready-made beds are made in the form of rectangles, polygons and squares. In small areas, vertical gardening is often carried out, the beds can also be made multi-tiered to get a complete landscape composition. Leafy spices, roots with a small depression (radishes, turnips, beets) are grown on multi-tiered structures.

Variants of forms of metal beds:

When there is a choice of kits, you should pay attention to a number of nuances:

- the presence of metal pegs, for beds in greenhouses, a support up to 25 cm long is enough, in an open garden - up to 40 cm;

- when deepening the boxes, it is desirable to have jumpers between the joints located parallel to each other.

Central stiffening ribs increase the loading capacity of the profile, strengthen the frame part of the bed.

Stiffeners should not be confused with edge line bends. Edges do not affect the mobility of the profile, do not increase the reliability of finished structures.

To strengthen long beds, screeds are used, installed between the sides

A buried bed is arranged in a pre-prepared trench. For biofuels, it is advisable to lay plant residues on the bottom, decomposing with the release of heat. Polymer fences are made in greenhouses and in open areas, the garden takes on a well-groomed, elegant look. There is no dirt on the site, typical for ordinary beds in the form of earthen ramparts with crumbling edges.