Metal frames market places ever higher demands on the accuracy of mating parts. Handling of metal tubes requires operation with high cutting quality. When choosing a technology must take into account material properties such as strength, heat resistance, conductivity, and others.

The subject of the pipes to be cut with plasma. The most effective technology having high productivity and processing accuracy.

3D plasma pipe cutting and its types

By definition, this process of separating the product into parts using a high-temperature plasma instead of mechanical, flame or laser cutter. There is also the milling, when the surface of the cut portion of the material while maintaining the integrity of the parts. Depending on the environment in which the process is divided as follows:

- Plain. The compressed air is used or nitrogen as a carrier;

- With the use of an inert gas. It improves the quality of cutting, because the process takes place in a clean environment;

- Water-cooled. It protects against overheating equipment, absorbs the harmful fumes.

By way of distinction arc cutting when the material is a component of an electrical circuit, and a jet is formed inside the arc torch.

How the plasma cutting pipes

Plasma is an ionized gas, electrically conductive. The gas stream under pressure is passed through the nozzle, where the particles are accelerated to the speed of sound. Between the nozzle and the surface of the pipe creates the electric arc. Under the influence of elektroplazmennoy arc heated to 20,000 degrees, the metal melts quickly. The liquid melt is removed from the surface of the high velocity gas stream.

Such a process is called direct and is used for materials having sufficient conductivity. cutting technique is called plasma-arc. This method has high productivity at a relatively low cost.

For metal pipes with a small conductivity indirect method is used, or plasma jet cutting. In this case, as mentioned, the arc is formed in the burner itself, and on material affects only the flow of hot ionized gas. The method requires increased cost and less productive.

Plasma cutting is endowed with a number of advantages:

- High-performance (at a thickness up to 50 mm);

- local heating respectively the absence of thermal deformation;

- quality cut at high speed;

- the possibility of cutting of complex lines;

- The edges do not need polishing.

The disadvantages are:

- a lot of noise at work;

- occurrence of cracks during bending fused slice.

Important! The use of 3D modeling allows you to create three-dimensional spatial images of objects with high accuracy. With the help of the equipment with special image management software is embodied in the metal.

3D plasma profile cutting of pipes makes it possible to produce the cutting and processing of complex contours on metal pipes of any section and profile, provides high accuracy subsequent mating parts without additional processing.

What is plasma cutting equipment

The complex consists of a hardware unit, a power supply, a mechanized torch. Plazmorez is a housing within which the nozzle with a twisting mechanism plasma medium, as well as the electrode and jacket cooling water. Connected to the gas line, in the absence thereof to a cylinder of compressed gas.

Distinguish device with rotating arc and without liquid-cooled or air. Water cooling allows for higher plasma temperature due to the high degree of gas compression.

Nozzles, electrodes are consumable items, the timely replacement of which is obligatory.

There are high-frequency electrodeless devices based on inductive coupling to a power source, and microwave plasma generators.

The distance between the nozzle and the surface should be in the range of 10 to 15 mm. If air is used as carrier, it must be cleaned and drained.

With the mechanization process device is placed on a fixed installation portal, portal or portal cantilever - pantograph type. As the displacement systems are used numerical control, the magnetic up linear speed adjustment.

The following are commonly used machines for cutting pipes.

Machine with numerical control

Machines allow plasma cutting of pipes of high accuracy with minimum marriage thanks to the CNC. Machine itself is controlled by a controller or a separate computer. The control program is created on the basis of three-dimensional model shape cut. In the presence of his sample, you can scan a special scanner that will allow to generate a 3D image in an electronic form.

Important! By varying the diameter of the plasma torches, the passage speed and the angle of inclination can be obtained a high quality cut of any complexity.

The main units, which is equipped with a cutter CNC:

- the plasma torch;

- controller;

- table saws;

- Caliper for moving the cutter;

- units for supplying gas, electricity and water.

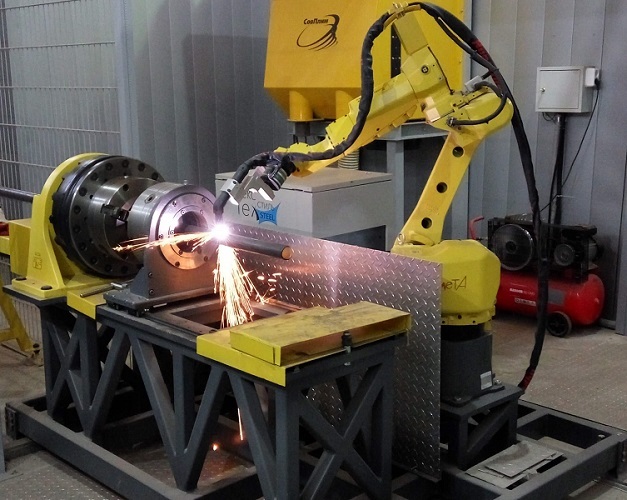

Robot

Thanks to software development is the increasing use of robotic cutting. Robots are widely used in the automotive, mechanical engineering and other fields. Previously, to reconfigure the equipment take weeks and even months. Who spent minutes. Therefore, the scope of the robots has expanded from the mass production of similar parts to fulfill individual orders.

In addition, automated systems provide continuous control of the set of process parameters, which drastically reduces the scrap rate.

Contemporary robots allow cuts at any angle at any location using a robotic arm that can be moved precisely in any direction. The long arm allows cutting of large-diameter pipes.

As an option, robotic systems can be equipped with sensor systems, vision systems, allowing to continuously monitor the process.

Thanks to the vision system is almost impossible to "not notice" the defective unit. Also, it becomes possible to detect deviations, then adjust settings during the process cycle.

Due to these factors robotic cutting is carried out on an inaccessible for manual labor level. It limits the use of high cost.

Universal cutting system ESR

This is the next stage in the development of technologies for plasma cutting pipes. The system extends the capabilities of conventional machines. Drilling, PUNCHING, threading, other work can be performed on a single machine with the ability to cut the figure. This significantly reduces the cost, time, resources, production areas.

The component parts of the system are:

- Spanner with program management;

- sliding elements that hold the tube in a horizontal position;

- the ventilation system.

Inside the pipe is installed on the bogie, each of which is selected on the basis of length and weight of the product. Above it is a traveling support with a burner attached to the portal that guarantees the free movement of support.

The processing tube is rotated about its longitudinal axis. Move horizontally synchronized with the rotation that allows precise positioning plazmorez.

3D head mounted CNC sets the desired angle of inclination and rotation of the plasma torch, allowing chamfer any complexity in a single pass. This saves time and money. The software has a database in which is stored a library of cuts and provides rapid creation of new ones.

Plasma cutting machine for pipes «Koral»

During the construction of pipelines, in other fields of technology require precise joint of large diameter pipes, sometimes several in one place. When misalignment increases the thickness of the weld, which leads to a reduction in strength and durability of the structure. The traditional method of marking tubes with patterns of paper laborious, lead to large errors in the accuracy of jointed parts.

Installation «Koral», developed by «Eckert», uses the ESR system and is a plasma cutter with a CNC. It is equipped with a 3D head with advanced software that allows precise cutting, ensure compliance with the dimensions specified products.

The control system is relatively simple, does not require a long complicated training. Application allows plasma arc shaped sections, the quality of which eliminates the subsequent processing of the flange. Release modifying «Koral» 300, «Koral» 600, «Koral» 900. Digital means limiting diameter of the pipe being treated.

Machine for high-precision plasma cutting pipes is fully automated and provides continuous arc height control, combustion temperature, gas pressure, over all process parameters process.

Important! The use of the machine makes it possible to reduce by several times the flange processing time compared to conventional methods.

metal processing technology made a qualitative leap forward, continue to flourish. There are new techniques, improving existing ones.

Plasma technology has a leading position among all the ways of metal processing thanks to the perfection of the process, high efficiency, reasonable combination of price and quality.