A tree has always been appreciated in the interior. From it, cabinets, tables, chairs, doors and frames are made. With the development of power tools, there appeared more opportunities for creating wooden objects of various shapes, and productivity has also increased substantially. One of these indispensable assistants is an electric car. A similar tool is available in every professional workshop and amateurs in the garage. At the dacha with his help it is possible to make the necessary furniture and appliances in the yard. Such construction equipment contains many parameters of choice, understanding which will be obtained by acquiring a tool that justifies the hopes placed on it for the implementation of tasks.

Contents:

- Best manufacturers of electric guns

- Principle of operation and device

- Types of electric guns

- Electro-gun choice parameters

- Which electrowelts choose

- How much does an electric drill

The best manufacturers of electric guns - which firm to choose

A quality construction tool traditionally has German or Japanese roots.

If you delve into all the features of electro slogging laziness, you can buy the company's products from the list below:

- Makita;

- DeWalt;

- Skil;

- Bosch;

- Hitachi.

But each of the presented firms has such a wide variety of models in terms of characteristics and capabilities that it is worth to look into the rating of the best electric guns.

The key features of the power tool itself and its purpose for different tasks are described below.

Principle of operation and device

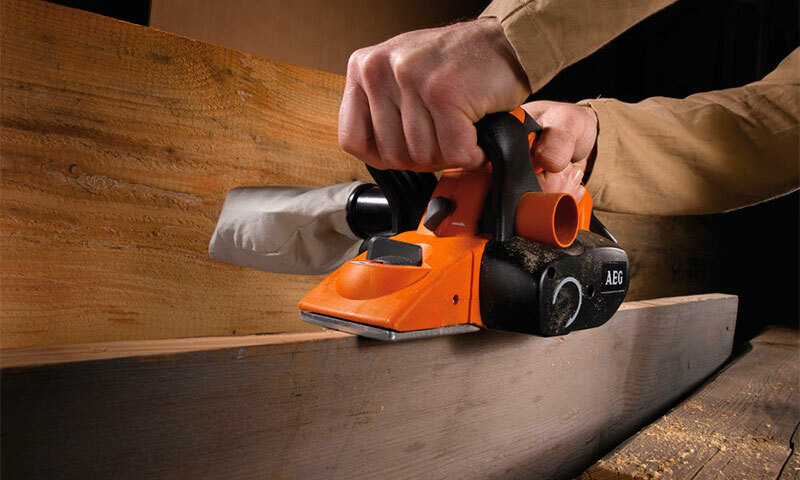

The electric shank is an analog of a conventional planer with the same function - removing the top layer of wood to create a perfectly flat surface.

Unlike the mechanical version, where everything depends on the magnitude of the vertical pressure on the part of the specialist and the force of longitudinal guidance, the electric hook itself "bites" into the solid wood and selects a certain layer due to the powerful motor and rotating knives.

With this tool you can perform:

- planing;

- sample of the quarter;

- edge mowing;

- fitting of wooden elements tightly to each other.

It has found a display in the manufacture of tables, cabinets, window sills, chairs, benches, pavilions, bedside tables and frames. The tool is used after rough processing of the tree. Usually trunks are blossomed on a sawmill, then they are delivered in the form of uncouth planks or sawn timber.

Drying removes excess moisture and slightly deforms the plane. The rough structure of the fibers and the roughness of the wood need further refinement, which is done by the electric gun, which helps to create a smooth surface.

At the final stage, the product is polished by a machine with petal circles and is ready for painting or varnishing.

To ensure the work at a high level, manufacturers carefully thought out the design and internal parts of the tool.

The device of the electric gun includes:

1. electric motor;

2. drum with knives;

3. belt drive;

4. main handle with start button;

5. auxiliary handle for uniform pressure and retention;

6. depth controller;

7. outsole;

8. channel for chip removal;

9. additional linear and limiting devices.

The principle of the tool is to rotate the motor from the power supply from the network. A gear belt driven by a casing connects the motor to the drum. On the latter are blades with a selected angle, which cut into the plane of the surface moving in parallel.

To regulate the depth of penetration into the material, there is a special base consisting of two parts - front and rear. One part of the platform is able to move up and down, and the second, with the cutting drum, remains at the same level.

The difference between the height of the parts of the skis and creates a difference for the cutting edge of the blade and determines what depth the tree will be lined with.

During operation, the removed layer of wood in the form of fine shavings and dust is diverted through a special channel to the side. Some models attach a bag that reduces the amount of sawdust in the air. In any case, it is necessary to wear safety goggles for using the electric gun.

Types of electric guns

Electro-guns for home and cottages

The main criterion for the difference between electric cars is their capacity. Models with a parameter from 0.5 to 1 kW are considered household. Their potential is sufficient to fulfill small or single tasks arising in a private home or cottage.

With daily use throughout the day, they are inefficient in terms of performance or break fast.

Pluses:

- inexpensive;

- acceptable power up to 1 kW;

- fine adjustment of depth;

- light weight;

- comfortable handles.

Disadvantages:

- on sale there are no necessary accessories for amateur versions;

- is harder to work with hard rock.

Professional electric guns

This group of products has a power from 1 to 2.2 kW.Such a stock allows you to quickly cope with any task in the woodworking industry or in a private workshop.

Professional models are practical for making interior doors, tables, bedside tables, window frames. It is convenient for them to handle solid rock massifs( oak, ash).The tool can work all day long and serve a long time.

Pluses:

- high power;

- use throughout the day;

- large number of additional devices;

- high revs;

- depth adjustment up to 18 mm;

- is a very smooth surface after the passage;

- wide area grip.

Disadvantages:

- expensive;

- many models are much heavier than amateur.

picker selection parameters The more the buyer will know about the key parameters of the tool, the more suitable the model will be able to choose. Let's consider some of them.

Power of the

This tool is produced with electric motors within the range of 0.5-2.2 kW.The power of the power unit affects the performance. The stronger the motor, the faster the plane can perform various manipulations.

1. If the device is purchased for periodic use and does not depend on the volume for the day, it is worth it to buy a model with a low output of 0.5-0.7 kW.This will save money.

2. In the professional field, the number of processed boards affects the number of products produced and can hinder the whole process and affect the work of other employees, therefore powerful power banks with an indicator of 1.2-1.5 kW are purchased here.

Working width

The job of an electric gun is to hold the tool along the surface. At a time, the machine processes exactly as much width as the blade and drum parameter allows. This index varies from 82 to 312 mm.

Models with intermediate indices of 110 and 170 mm are common. It turns out that the board with a width of 1000 mm electrobrushes with a minimum value of the ski( 82 mm) will handle 12 passes, and a tool with an index of 110 mm for 9 times. This saves time and effort.

But the presence of a wide base and the corresponding drum is justified only in case of working with large boards, because the bar of 150 mm will have to be reused by both kinds of tools.

1. Ski with parameters of 82 mm worth buying for the manufacture of window frames, polishing beams, racks, chairs.

2. Wider models with a base of 110-170 mm suitable for large products: tables, doors, cabinets.

Idling frequency

This parameter specifies how many revolutions per minute the drum will make without load on the surface. On each rotational element there are several blades. The number of turns shows how many times each blade touches the material, and therefore how quickly it will work.

It is not necessary to identify the speed of rotation with power, since models with the same value of kW are capable of varying the number of revolutions. This is achieved through the details in the torque transmission system and the drum unit.

The idle frequency run-up is 12000-19000 rpm.

1. For a rare application in the country, it is enough to measure 12000-13000 rpm.

2. For professional activities, you need to choose a model of 15000-19000 rpm.

Depth of sampling

The number of cut millimeters on the surface depends on the difference in the level of the two parts of the ski. To regulate this difference, a rotation system and a knob for tuning are provided. Electro-banks can shoot from 0.1 to 18 mm, but each model has its own range.

1. The tool with a large takeoff from 0.1 to 10 mm is important for those who deal only with sawn boards, possibly with bark on their sides. Adjusting the plane to a deep level can quickly remove a less dense layer.

2. For those who work with an already dried board, on which it is required to correct the last irregularities, there are enough models with a parameter of 0.1-2 mm.

Thanks to the electric gun it is possible to choose a part of the corner for accurate joining of wooden parts. This applies in the production of furniture and windows.

Sometimes it is necessary to shoot up to 10 mm to produce enough seat and install additional wooden elements, so here the depth of the sample plays an important role and models with an index of up to 4-5 mm will be required.

Having a groove on the sole

The base of the electric gun running in front of the knives can contain one or more V-grooves.

1. If the tool is used only for grinding flat boards( beams, beams), then you can buy a model without grooves.

2. For the production of benches, countertops and windows, the beautiful bevels of the edges are extremely important, making the product more accurate, so the presence of a groove on the sole is very useful.

Quarter selection

In some models, the drum is not located in the middle, but is shifted to one side of the tool. This allows you to close it to the end of the board and select a small part, while the body of the device does not interfere with the execution, and on the front side of the apparatus there is a stop for holding an equal distance along the entire length of the board.

Weight of the tool

Electro-guns weigh from 2.5 to 9 kg. Often a large mass of professional models. In part this helps in pressing the product and tight fitting the sole of the tool. Therefore, people with low weight and poor physical preparation will be able to better surface treatment device with a mass of 6-8 kg.

The same parameters should be chosen for those who work throughout the day, because constantly press on top of the unit is very tiring, and with a heavy model it is enough to push it along the machined surface along.

But there are jobs not on the table, but in a vertical spatial position( grouting unevenness in the already built gazebo, bench, frame).Here it will be more convenient to work with a tool with a small weight of 2.5-3 kg. The same parameter is suitable for dachas.

Convenience of the handle

This parameter is difficult to evaluate visually from the picture in the online store, so you need to hold the goods in hand and feel the distribution of weight, balancing, the convenience of capture and retention.

Each electric drill is supplied with a main handle with a trigger. Pressing the latter should not be with the interception, but directly from the main position of the hand.

The auxiliary handle is appreciated with a pronounced mushroom shape so that it is possible to lift the tool if necessary. The coating is preferably rubberized to easily hold the device in sweaty hands.

Dust collector

During operation, the electric gun costs a lot of dust( the wooden fiber is ground with knives in the form of small sawdust and shavings).All this flies on clothes, on the floor and in the eyes. The organs of vision should be protected with glasses from small particles. After doing the work, you have to clean up the room for a long time.

Partially to get rid of these problems will help the dust collector, which is installed on the outlet from under the knives and catches most of the debris. This device will be especially practical for those working inside the building( workshop, workshop, garage).

Additional parameters of

1. Some electric guns are equipped with a parallel limiter to control the smoothness of reference. It is not important in simple polishing of the surface for doors or countertops, but it is important in case of choosing a quarter or removing the layer only from the edge of the board for decorative processing.

2. The kit can contain a small frame that locks the electric hooks upside down. This is practical for processing narrow bars, which the master holds in his hands, and the tool uses as a desktop machine.

3. Soft start allows you to give a gradual load from the engine to the drum. This allows you to safely take the instrument in your hand, get over the product and, pressing the button, accurately bring the skis to the place where the processing begins.

Which electrolink to choose

1. To work with large surfaces( production of tables, wardrobes, interior doors), you need a wide electric car with a ski 110-170 mm and a power of 1.5 kW.The depth of removal of enough models with an index of 2-3 mm. The number of revolutions is not less than 14,000 per minute. Useful in 5-6 kg.

2. To produce windows and frames, you need a tool with a width of 82 mm and a power of 1.2-1.6 kW.In this kind of activity, V-shaped grooves on the ski are very useful for removing beautiful decorative facets. The depth of the sample is 3-4 mm. The idling frequency is 15,000 rpm.

3. For those who work with hard woods( oak, cedar, ash), you need a 2.2 kW electric hook, a rubber grip and the possibility of changing the depth of sample to 3 mm. It will require a high rotation speed of the drum around 18,000-19,000 rpm. It will be convenient to operate the device with a weight of 7-9 kg.

4. For a summer residence and periodic works on setting a fence or making a bench, a model with a capacity of 0.6 kW is sufficient, and the possibility of penetration is up to 4 mm. Suitable lightweight unit up to 3 kg and 12,000 rpm.

How much does an

electric drill 1. For the treatment of large surface areas, the models have a cost of 12,000-26,000 rubles.

2. A practical tool for manufacturing windows and frames will cost 6000-10000 rubles.

3. Powerful models easily coping with hard rocks and having a large mass cost over 100,000 rubles.

4. Variants of electric cars for cottages start from 2000 to 6000 rubles.