Comfortable and functional mattress - not just an element of the organization of a berth. Not only the quality of sleep, comfort and convenience depend on the correct choice of this accessory. The mattress is the key link in the matter of caring for the health of the spine and the musculoskeletal system. Modern manufacturers offer a wide range of orthopedic mattresses with different filling and performance characteristics.

Contents:

- best manufacturers of orthopedic mattresses

- types and device mattresses

- Selection Options orthopedic mattress

- What memory foam mattresses to choose

- How much is a memory foam mattresses

best manufacturers of orthopedic mattresses - which firm to choose

process of choosing and buying a mattress should begin with a studymarket producers. Today, dozens of manufacturers are offering their products to the Russian consumer. Preference should be given to reliable and proven trademarks, whose products undergo strict quality control and are confirmed by a guarantee. Conscientious manufacturers give a warranty period for products from 6 months to 10 years.

The most famous brands on the domestic market are:

- Ascona;

- Toris;

- Ormatek;

- Dreamline;

- Toris;

- Mediflex;

- Vegas;

- Consul.

The assortment of manufacturers offers various mattress lines for children and adults. The mattresses of proven brands are not products made "on your knees".The production of both budget and elite models is carried out using modern high-tech equipment, using high-quality, reliable materials. Therefore, the preference for a well-known brand is not a tribute to fashion, but a worthy choice in favor of quality and reliability.

- See also: rating of the best orthopedic mattresses

Types and the device of orthopedic mattresses

With the dependent spring unit

Mattresses with a dependent spring unit are made on the basis of blocks of Boncon double-cone springs, for which sometimes they are called "Bonnel springs".The high quality of such a spring unit can only be provided by a machine assembly on good equipment.

At manual assembly there is a probability of fast loosening of springs and, as consequence, - the mattress will creak. Determine the quality of assembly "by eye" is impossible, so when buying a mattress should be given to a reliable and proven manufacturer.

Pros:

- light weight;

- reasonable price;

- good ventilation.

Cons:

- can make a creak from the contact of the metal surfaces of the springs;

- under the impact of the load bends over the entire surface of the mattress, creating a bias towards the partner on the double models;

- fragility - quickly lose shape;

- have an unpleasant property of accumulating static electricity and "beating" the current.

With independent springs

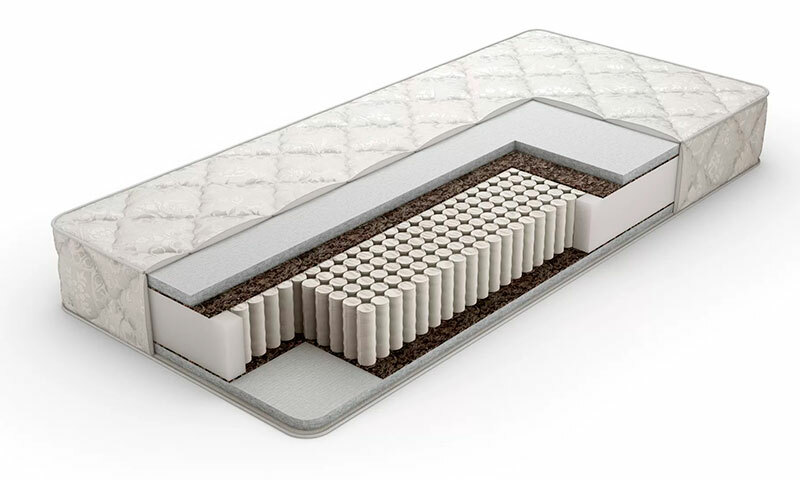

The mattress based on the block of independent springs is more expensive than the models with the Bonnel spring unit, but it has significant advantages. The main feature of this type of product is the use of spring blocks, in which each spring is cylindrical or barrel-shaped, packed in a separate fabric case.

Springs here have a smaller diameter, so the block density is much higher - from 250 to 1000 or more pieces per sq.m. Unlike Bonnel units, springs are not connected to each other, they bend only in places of loading, which allows to ensure an optimal position of the spine and distribute the load to several points.

Models of some manufacturers are presented with mattresses with conventional blocks of independent springs with a quantity of 250-1 200 per sq.m.and so-called "multipack" - a spring unit with a maximum density, which can be up to 1500-1700 per sq.m.

In some elite "multipacks", springs of different degree of elasticity can be used, which provides an increased orthopedic effect.

Pros:

- high anatomy - take the shape of the body;

- withstand heavy loads;

- longevity - permanently retains its shape.

Cons:

- high cost.

- is the likelihood of the appearance of a squeak, but not as quickly as a Bonnet mattress.

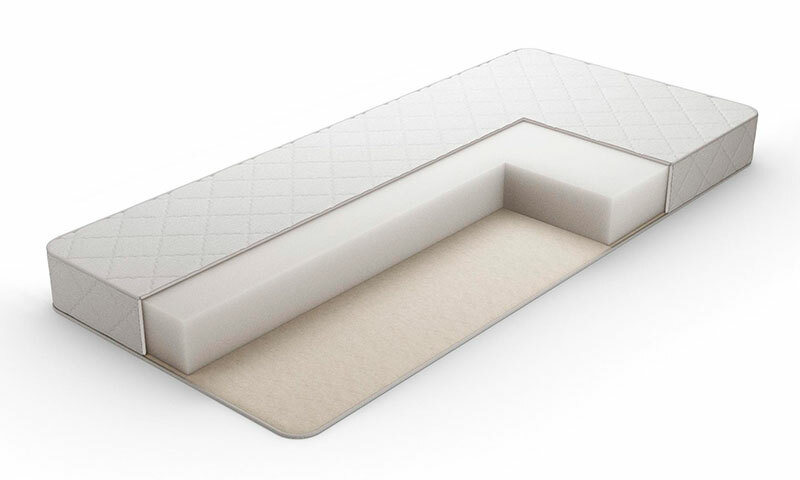

Springless mattresses

Spring blocks are not used in the production of springless mattresses. Orthopedic effect and rigidity are provided and regulated by different layers of materials with different properties and degree of elasticity.

Pros:

- noiseless - there is no chance of creaking even with prolonged use;

- wear resistance - permanently retains its shape;

- durability - average service life of about 15 years;

- evenly distributes the load;

- does not accumulate static electricity.

Cons:

- high cost - springless models are among the most expensive types of mattresses.

Options for choosing an orthopedic mattress

The main parameters that determine the performance of the mattress are:

1. size of the berth;

2. the biological age of a person;

3. anatomical features of

4. lifestyle and level of physical activity;

5. height and weight;

6. individual preferences.

Rigidity

An important criterion for choosing a mattress is its degree of rigidity. Using layers of coconut coir, horsehair, and spring blocks with the maximum number of springs per square meter increases the stiffness and elasticity of the mattress. Latex, polyurethane foam, sintepon, modern synthetic materials, perioth( artificial wool substitute), strufofiber( nonwoven fluffy synthetic material) give the mattress softness.

The memory effect of

Special attention should be paid to the modern high-tech material used by manufacturers in the production of luxury mattresses - a viscoelastic Memory Foam foam that provides increased anatomical effect.

A distinctive feature of this material is the ability to take the shape of the body during sleep - the so-called "memory" effect. After application, the mattress acquires the initial form. Such models are characterized by an increased level of comfort, allow the muscles to relax during sleep.

Case

High quality fabric cover - an important factor that determines the functionality and duration of the product. Today, when manufacturing mattresses, manufacturers use both natural fabrics and synthetic substitutes. The latter are not the best option, as they are electrified and "shocked" during use.

The optimal characteristics are natural Jacquard fabrics, which include about 70% natural and 30% artificial fibers. Special weaving of yarns of such fabrics ensures maximum strength and elasticity of the surface.

Lightning and quilting

When evaluating the quality of the mattress, special attention should be paid to the quilting. It should be frequent, deep - grab all layers of tissue, and have no gaps in the seams. Otherwise, the cover will quickly wear out and become unusable.

Lightning on the mattress is a convenient option that not all manufacturers offer. But its presence will greatly simplify the care of the product and will facilitate the process of its cleaning.

Filler

As fillers, modern manufacturers use both natural and synthetic synthetic materials:

1. polyurethane foam;

2. latex;

3. foam rubber;

4. coconut coir;

5. seaweed;

6. struttoiber;

7. felt;

8. wool.

These same fillers are also used in the manufacture of spring mattresses, giving the mattress additional performance characteristics.

When choosing a mattress, it should be taken into account that under rigid fillers - such as coconut coir, the orthopedic effect of the springs is minimized. Therefore, if you buy a mattress with a spring block, pay attention to the fact that the top layer was made of a soft filler.

Which orthopedic mattress to choose

The first thing to remember when choosing a mattress is that the fashionable term "orthopedic" is, for the most part, an advertising gimmick. Orthopedic - that is, a supportive and curative effect - will be able to provide only products manufactured under the guidance or recommendations of an orthopedic physician for a particular person, taking into account its physiological characteristics.

The main task of modern orthopedic mattresses, manufactured in-line, is to create the most comfortable conditions for sleeping and rest, ensuring the correct position of the body and load distribution.

1. Children and young adults are advised to use more rigid mattresses. The older the person, the more soft mattress he should choose.

2. For matrimonial people, athletes and those whose work is associated with high physical stress, mattresses of increased rigidity are recommended.

3. Also, when buying a mattress, you need to consider anthropometric data - height, weight. If your weight is from 40 to 60 kg, the best option is a soft mattress or a model of medium hardness.

4. For adults weighing 60 to 90 kg, the best choice is a mattress with medium stiffness, while at a weight over 90 kg, soft models should be preferred.

5. Taking into account the growth, the mattress is chosen as follows: human height + minimum 15 cm.

6. For diseases of the musculoskeletal system, pain in the spine, attention should be paid to rigid models. However, in most cases, individual physiological characteristics are taken into account.

How much does the orthopedic mattress

1. The segment of the economy class includes mattresses with a Bonnel spring block or springless products, which are based on polyurethane foam, batting or struttoiber. The range of prices of such models ranges from 2,500 to 10,000-15,000 rubles.

2. The average price segment - mattresses with an independent spring unit, the number of springs in which is from 250 to 700. The cost of such products varies from 6 000 to 25 000-30 000 rub.

3. The category of elite mattresses includes products with an independent spring unit, where the number of springs exceeds 700 pieces per square meter, as well as springless mattresses, in which high-quality materials are used as a filler. The prices for such products are more than 30 000 rubles.

4. There are models, the cost of which can exceed this figure by several times, and in some cases - even several dozen times.