Cottages are built and wooden, and brick, and stone. And they have different number of storeys, from one to three floors. And you need to climb the floors, and for this you need stairs. In a wooden house, to maintain the unity of style and uniformity of design and technological solutions, a wooden staircase looks natural. But in brick, block or stone houses, concrete stairs are very popular. And their design is diverse, and the technology is available for repetition.

Read in the article

- 1 Features of concrete stairs

- 2 Varieties

- 2.1 Straight

- 2.2 Swivel

- 2.3 continuous

- 3 Advantages and disadvantages

- 4 building codes

- 5 Safety requirements

- 6 How to build a concrete staircase to the second floor

- 6.1 Materials and tools

- 6.2 Parameter calculation and drawing

- 6.3 Preparatory work

- 6.4 Formwork installation

- 6.5 Rebar laying

- 6.6 Pouring concrete

- 6.7 Formwork dismantling

- 6.8 Handrail installation

- 6.9 Finishing actions

- 6.9.1 wood finish

- 6.9.2 Facing with ceramic tiles

- 6.9.3 Mounting the backlight

- 7 The nuances of making stairs to the porch

- 8 Photo gallery of stylish stairs for a private house

- 9 Conclusion

Features of concrete stairs

A concrete staircase can be built both inside the building and outside. There are no limiting requirements for either humidity or temperature. The durability of such stairs is almost eternal, because concrete is stronger than any building material. The casting elements do not change the strength of the connection over time, the steps will never creak. Concrete is not combustible, and even during a fire, a ladder can be used to save.

Concrete is an ideal material for the creativity of a visionary designer. Concrete stairs can be made in any configuration. Concrete goes well with different materials and harmonizes with marble, wrought iron, glass, ceramic, wood finishes.

Varieties

Concrete stairs are classified according to different criteria: by purpose, technology, form, location, design complexity. Stairs can be monolithic and prefabricated, mid-flight and spiral, external and internal, from one material (concrete) and combined (concrete, metal, wood).

Straight

Straight stairs belong to the marching group. Several straight flights (flights) make up the design of the stairs. Marches are connected into a single staircase design with platforms or turning steps.

Swivel

Turning marches are also elements of the stairs. They come with a 90 degree turn.G-shaped) and 180 degrees (P-shaped).

continuous

Continuous marches connect the two floors. This is a continuous straight ladder, easy to climb and descend. The angle of inclination of the march to the horizon is approximately 40 degrees.

Advantages and disadvantages

Like any product, a concrete staircase can be characterized by an extensive list of advantages and disadvantages, but it has more advantages.

A concrete staircase can be built with an individual, unique design - no one else will have one like it. The concrete product has high flexural, compressive, tensile and impact strength. The product is resistant to any weather conditions and tolerates any humidity without loss of properties. Does not burn, tolerates any temperature. The steps do not creak, absolutely silent. You can choose any finish. For the designer there is a large field for creative fantasies.

The disadvantages are much less. Concrete structures have a very large weight, and the stairs have to be placed on a powerful foundation. The construction of a concrete staircase is a labor-intensive process that takes a long time. Concrete after pouring hardens for a long time, and all this time the stairs cannot be used.

building codes

Requirements for stairs are focused on ensuring their maximum safety and comfort for ascent and descent. The main documents regulating the design are state standards (GOST) and building codes and regulations (SNiP).

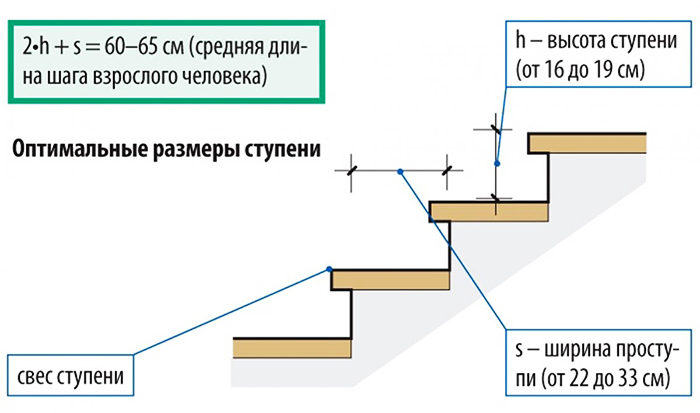

The norms, in particular, prohibit the use of attached and transformable structures for connecting residential floors. The width of the flight of stairs should provide a throughput for the passage of one person at least 80 cm, for two - 100 cm. A staircase along its entire length and in all spans cannot be built narrower than the doorway leading to it. The width of the stairs should be built along the entire length of the same. Between two marches going in opposite directions, there must be a gap of 5 cm wide. The height of one step should be in the range of 12–20 cm. The depth of the tread (support platform for the foot) is 24–30 cm. The sum of these values \u200b\u200bshould fit into 43–47 cm.

The requirements must also be met by landings located on turns between spans. Their width should not be less than the width of the flight of stairs. The length of the undercarriage of the platform between the spans should not be shorter than 130-140 cm, and the depth of the platform in front of the interior door or the entrance to the house should not be less than 100 cm.

Safety requirements

Building codes (SNiP) are aimed at ensuring safety. According to the rules, stairs with more than three steps must be designed with a fence or handrails.

In private homes, the rules regulate the minimum height of the fence. Its height must be at least 90 cm. For young children, the height of the fences is required up to 120-150 cm and two rows of handrails are built. For fences that do not have continuous filling, the step between the balusters should be 10–15 cm.

How to build a concrete staircase to the second floor

For the construction of a concrete staircase, you will need to calculate the parameters, make a drawing and prepare the necessary tools and materials.

Materials and tools

For the construction of formwork, you will need a set of carpentry tools: a saw, a planer, a hammer, a nail puller, a drill. We need fasteners (nails of different sizes), as well as cement with sand. Probably, it still makes sense to order a batch of concrete in production: both the quantity will be required, and the quality for the stairs needs to be high.

The staircase is built using reinforcement; wire is required to tie the reinforcement into a single whole. You also need a metalwork tool: pliers, wire cutters. If fences and other finishes have already been thought out, you need to take care of the materials for their manufacture. And mortgages for fixing the railing must be laid before the start of pouring concrete.

Parameter calculation and drawing

The calculation of the dimensions of the staircase structure does not require pharmaceutical accuracy. All the time you have to make adjustments for the real possibilities in a particular house. Calculation methods allow reasonable tolerances for deviations from the calculated dimensions. You can usually get by with them.

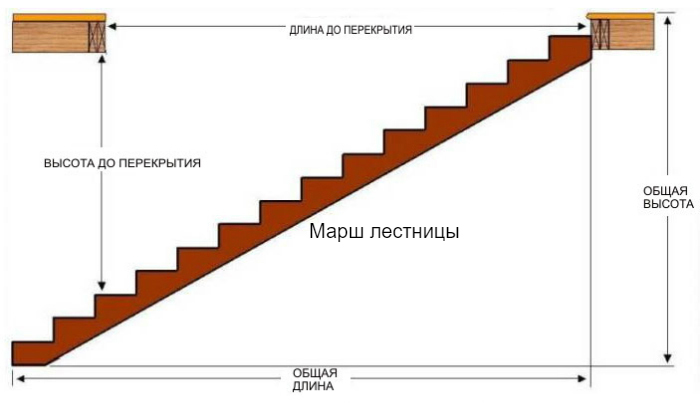

The main parameters of the stairs in the calculation are the height of the structure, the angle of elevation, the length of the flight of stairs, the number and height of the steps.

The angle of inclination of the stairs and the dimensions of the steps are determined individually for each specific case, being tied to the dimensions of the room. The standard angles are 25, 35 and 45 degrees. The latter option is considered optimal in terms of safety, ease of movement and saving building materials. Given the angle, you should determine the height and width of the steps.

The optimal dimensions are the height of the riser 160–200 mm, the width of the tread 270–300 mm. The width of the march is selected in accordance with these dimensions. The approximate number of steps is determined as the result of dividing the height of the march by the height of the riser. After choosing the main dimensions, it is necessary to make drawings of each march and each platform, and the formwork for them.

Preparatory work

A critical part of the construction work is the marking of the location of the elements of the stairs on the stable structural elements of the house: on the walls, on the floor and ceiling. A line of the real profile of the staircase under construction is applied to the wall surface. A solid base must be prepared on which the lower edge of the ladder will rest. The top edge should lie on the prepared support. Preparatory work also includes the preparation of formwork parts.

Formwork installation

The formwork is calculated on resistance to big loadings. It is made from a board with a section of at least 50 x 150 mm. The march will adjoin the main wall of the house, so one wall of the formwork is attached to this wall. Concrete dowels are used for fastening. The lower edge of the beam is cut at an angle so that the beam rests on the floor with a wider base. A through hole is drilled through the beam and the floor, a dowel is inserted into it and screwed up to the stop. In the same way, the upper edge of the beam is attached, and one dowel is installed in the wall at half the length of the beam.

The formwork frame is based on two beams, one of which is attached to the wall of the house, and the second lies strictly parallel to the first on supports. The main load created by the casting will be taken by the supports, which are installed on the wall beam at a distance of half a meter between the formwork beams and the floor. The supports for the second beam are not installed from the bottom of the beam, but overlapped, and more often with a step of 0.4 m. The outer sidewall of the formwork will be attached to the upper protruding part. Deck rails are attached to the beams with a step of 0.3 m.

Both the appearance and the service life of the stairs depend on the quality of the formwork assembly. To assemble the formwork, you will need waterproof plywood 12–18 mm thick or a planed edged board 25–30 mm thick. From this material, shields will be formed for casting various parts of the stairs. From a bar of 100 x 100 mm, supports are made for the lower shields. The assembly of shields is carried out using a steel corner. All fastenings are made with self-tapping screws. Disassembling a structure assembled on self-tapping screws is much easier than pulling out nails.

Laying and fastening of all formwork parts are carefully controlled by geometric parameters: parallelism, perpendicularity, verticality and horizontality. The lower part of the formwork assembled from the boards is laid on retaining bars. Steps and risers are formed from boards. The lower part of the formwork during pouring will experience the greatest deflection forces. So that the shape of the steps does not change, this part of the formwork frame is reinforced additionally. You can install an external board.

As for pouring concrete, it is performed after the creation of the reinforcing cage. The entire inner surface of the formwork must be carefully cleaned with a grinder. All joints are covered with a cement-sand mixture. Then the casting surfaces will have a decent appearance.

Rebar laying

Reinforcement of a monolithic concrete staircase is necessary to increase the resistance to bending and tensile forces. The reinforcement forms a frame that increases the strength of the concrete casting, prevents the appearance of cracks, and prolongs the life of the product. But you need special rods. Too thick are undesirable, they do not add strength, but only increase the weight of the structure.

When creating a reinforcing cage, first longitudinal rods are laid with a step of 19 cm, then transverse rods with a step of 20 cm. The rods are either welded at the crosshairs to each other, or tied with a soft wire. Between the reinforcing cage and the bottom of the formwork along the entire length there should be a gap of 3 cm.

Pouring concrete

The concrete solution must have certain qualities. It should not be very liquid, but should stick to the trowel. Since the filling is performed without interruption, a large amount of the mixture will be required. It is physically difficult to do it yourself, so it is better to order concrete from the factory.

The freshly poured surface is leveled with a trowel or building rule. Excess concrete is thrown with a trowel to the upper, not yet filled steps. So that the concrete does not crack, after pouring it must be covered with a film, and in hot weather it must be watered daily.

Formwork dismantling

Formwork boards and crossbeams can be removed after seven days. And you can start doing rough grinding. It is possible to completely remove the formwork, including the bottom, after 28 days. This is the time of complete solidification of concrete. Disassembly must be carried out carefully, unscrewing the screws.

Handrail installation

The railing on the stairs has two functions: they provide safety and comfort when walking up the stairs and are an element of decoration. This design consists of two parts - racks or balusters and the railing itself. All together is called a fence. Balusters need to be installed firmly, firmly on the stairs, and railings should be put on them.

The builders worked out the procedure for installing the fence. First, extreme support pillars are installed: the first one is at the first step, and the second one is at the nearest platform. Balusters are fixed in the marked places on the steps or on the bowstring. The tops are aligned along the twine, the vertical position is ensured in all planes. After that, the railings are installed.

Finishing actions

A concrete product in a residential building looks too harsh and cold, you need to give it more comfort and warmth.

wood finish

Most often, the finishing of a concrete staircase is done with wood. Such work is carried out only indoors. The greatest effect is given by the complete cladding of concrete with wood. The concrete is hidden and the stairs look like they are made entirely of wood. The type of wood, the size of the wooden panels matters. If the steps of the stairs have an overhang, then a material with a thickness of 30 mm should be used to cover them, if without an overhang, a thinner one can be used. Riser can be made from cheaper wood.

Facing with ceramic tiles

Ceramic tiles give the stairs a completely different look. The tile must be marked in place and cut if necessary. Laying is carried out from the top floor down. The adhesive composition is applied to the base. First of all, the tiles are laid on the risers.

Mounting the backlight

Stair lighting is a very useful feature and can be implemented in many ways. The easiest option is to hang 2-3 light bulbs on the wall along the stairs, and two switches at the top and bottom so that you can turn the light on or off from anyone.

A more elegant way is to equip each step with an LED strip, and connect the switch to a motion sensor. A man approached - the steps light up, he left - they went out. You can make an individual automatic activation of each step that a person is just about to step on - both beauty and economy. And there are many more interesting technical and design options.

The nuances of making stairs to the porch

The stairs to the porch should always be concrete or stone. She has few steps, 3 or 4, but they are much wider than those in the house. Railings to it can not be done. With its appearance, it should be the first (before the entrance) decoration of the house.

Photo gallery of stylish stairs for a private house

Staircase lighting is both beautiful and practical.

A wooden staircase is the easiest and cheapest option.

Stairs can be built in any shape.

Conclusion

Now one-story houses are rarely built: the owners need freedom, and they need to receive guests. It's hard to get to the second floor without a ladder. So people build stairs, showing their technical, architectural and artistic talents.

I've been looking at buying a sauna for a long time. I recently found exactly that one at an exhibition in Zyablikovo ...

A friend designed a garage for me. It remains only to find a team for implementation. Well on…

Guys, it's not complete. You don't mention Domorost, but still these guys have a problem...

Hello, thank you for the informative information. Health to you and your loved ones. Sk…

From strong winds, fences sometimes fall if they are installed unreliably. We have our own at Terem-p ...

We bought a summer cottage with a dilapidated country house. They restored it through the tower. AND …

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?

Four days ago I ordered a Revolts heating kit for our dacha. I'm going to pick up tomorrow...

If the apartment is ready, then why doesn’t Buzova broadcast to the whole world about moving and living ...

Like 10m. Enough tape for 1.5m of fence?!

This is most likely an Internet modem like yota. And, I remember, they used both polarizers ...