Artificial stone is a very popular finishing material, and if you are interested in this topic, so you already more or less imagine what you need it for and what kind of this finishing material would need. All you need to do is to pay an amount for the goods, and not so small. But at this stage, difficulties may arise. However, they can be avoided if you know how to make an artificial stone at home. This is what we'll talk about today.

Read in the article

- 1 How to make a mold for artificial stone with your own hands

- 1.1 What to make a form

- 1.2 How to make a polyurethane mold

- 2 How to make an artificial stone from gypsum

- 3 How to make cobblestone from cement

- 4 Acrylic stone: is it possible to do it yourself

- 5 How to make flexible stone

- 6 How to fix artificial stone on the wall

How to make a mold for artificial stone with your own hands

Form is the key to solving the problem. Whatever mixture you use, you will not get the expected result without the appropriate fill. You can, of course, fork out here too: silicone molds of various formats are sold both in online hypermarkets and in ordinary hardware stores. On average, the cost of a product is about two thousand rubles. And in order to fill in a sufficient number of samples for the house, you will need not one, but at least 5-8 pieces. It turns out that the purchase is a very costly business. In the meantime, here you can save a lot.

In addition, you will get the opportunity to make your product individual, unlike any other. And not just individual, but even nominal - why not add a letter or some kind of monogram to the design?

If you once try to independently make a mold and a stone, then later you can apply the acquired skills in the production of other details - sculptures or balusters.

On average, one form, even one made by yourself, is able to withstand the operation of 1000 pours, so you can make a stone not only for yourself, but also for sale.

What to make a form

There are several materials that are suitable for this purpose:

- Silicone - one of the most elastic and durable materials for mold making. It is actively used to form matrices not only for building fill, but also for various household needs, from cooking to cosmetics. Of course, for the manufacture of artificial stone, you will need thick, dense silicone that holds its shape well, without blurring under the weight of the contents. The problem with mold making is the difficulty of removing air bubbles - a vacuum machine is required.

- Polyurethane - a solid base that will be more durable than silicone, and, accordingly, will withstand more pours. This material is resistant to aggressive chemicals. To remove air bubbles, the mold during manufacture must be heated with a building hair dryer.

- Plastic - This is the most rigid form with thin walls. Plastic is not afraid of aggressive chemistry, confidently holds its shape and is suitable not only for the manufacture of various types of artificial stone, but also for the formation of paving slabs. The tile is formed using vibration shrinkage, and this creates an increased load on the mold. Plastic is not afraid of such a load. You cannot make a plastic mold yourself, so in our question it disappears.

It is not difficult to prepare a polyurethane mold, and there is no need for specific devices such as a vacuum machine.

How to make a polyurethane mold

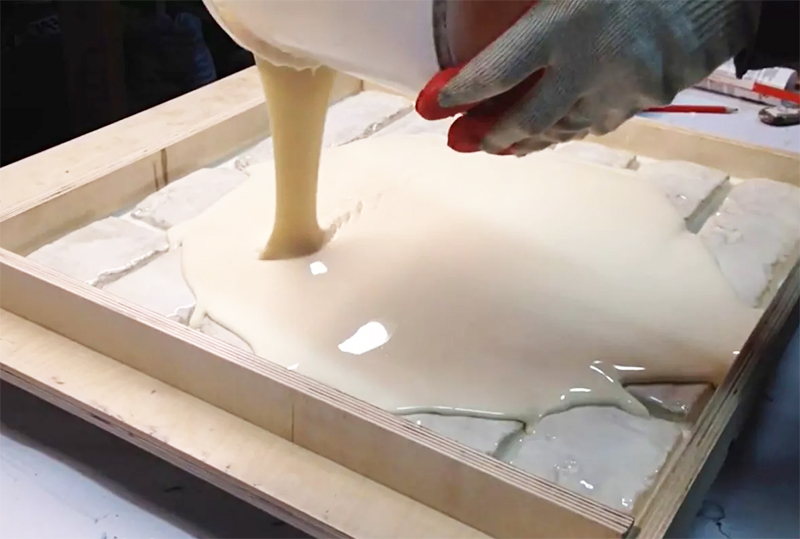

The main task in the manufacture of the mold is to force the liquid polyurethane to harden, while maintaining the desired shape. To work, you need a table with a flat surface and a room with room temperature. You need to prepare a piece of laminated plywood or similar lacquered material in the size of the shape you want to get. Along the perimeter of the workpiece, sides are made with a height of at least 5 cm.

For the manufacture of the matrix, you will need an acrylic sealant, moment glue or PVA and a building hair dryer.

Remember that for gypsum casting, it is necessary to provide for a product thickness of no more than 50 mm, and for concrete - no more than 30. And, importantly, your master model must be flat on one side, otherwise how will you attach it to the wall during finishing?

First, the master models are placed on the bottom of the box and distributed so that there is a distance of at least 2 cm between them. To prevent the stones from shifting during work, first make markings along the edges with a marker, and then glue them to the base with glue. All cracks in the box are carefully covered with sealant so that the polyurethane does not leak out.

Formwork and master models are lubricated with machine oil. It is especially important to carefully apply oil to porous stones, otherwise you simply will not separate them from the mold. The form itself is set strictly in a horizontal position, checking it with a building level.

The polyurethane mixture is prepared according to the manufacturer's instructions and poured into the exposed mold. To make the matrix more durable, you can strengthen it with a reinforcing mesh. When the mixture has hardened, carefully remove the master models and remove excess sagging.

How to make an artificial stone from gypsum

To make artificial stone, you will need building gypsum in powder form. To determine the quality of this raw material, pay attention to the marking: there should be the letter R and a numerical value next to it. The higher the number, the better the mixture. The most durable brand is R-16. The stone made from it tolerates transportation well and is even suitable for the manufacture of products for sale. Also consider buying mixtures in which plasticizers and additives were initially introduced to increase strength - all this is reflected in the labeling.

When choosing gypsum, you should pay attention to the color of the mixture. White is easy to tint, and you are guaranteed to get the right color, which is not the case with gray powder.

To make a stone, you will need a form, a container for kneading with a flat bottom, a scale for weighing components, sand, water, dye, a spatula, laundry soap.

So that the finished stones can be easily removed from the mold, it is pre-lubricated with soapy water. Laundry soap shavings are dissolved in warm water and applied with a soft brush to the inside of the mold. A brush can replace a spray bottle.

Gypsum is kneaded strictly in the amount necessary for one pour. It dries quickly and you just can't use the excess. Pour water into the mixing container and, stirring constantly, add the powder. Do not pour the powder all at once - in this case, you will not be able to mix it to obtain a homogeneous mass. At the same time, when kneading, dye is added to the mixture.

When the composition is ready for pouring, first a thin layer is applied to the inside of the mold, carefully distributing it over all irregularities so that voids and bubbles do not turn out. Then the bulk is poured and the upper part is leveled with a spatula, without any effort. Too much pressure can make the surface uneven.

After pouring, the mold must be covered with a piece of polyethylene or glass and slightly vibrated. This can be done by simply shaking the surface of the table to fill in possible voids.

Half an hour is enough to harden a layer of gypsum up to 5 cm thick. After the film is removed and the finished stones are carefully removed. If necessary, make a drawing on the stone with a brush or a soft sponge.

How to make cobblestone from cement

Artificial stone is used not only for wall cladding in the interior. With it, you can decorate landscape design or even hide some unsightly details, such as a cover on a well. And you can make it with your own hands, even without a form for pouring.

To make a boulder, you will need some kind of frame: it can be an empty bottle, a bunch of bags, a cardboard box, you can build a foam base. All this is given the shape of a stone and fitted with a reinforcing mesh. For the solution, cement is mixed with sand in a ratio of 1 to 3 and the solution is made thick so that it does not drain from the mold. The solution is applied in stages, in several layers, allowing the initial layer to dry. Only the last, final layer is leveled, and the solution for it is made more liquid. At this stage, you can smooth out the protrusions and give them a more natural shape.

If you need an even lighter version of artificial stone, then use burlap. It is impregnated with cement mortar and wrapped around the form. After hardening, the surface is leveled with a thin layer of concrete.

Acrylic stone: is it possible to do it yourself

Acrylic stone is a relatively new finishing material that shows excellent results in durability and strength. Yes, it is not as resistant to possible damage as, say, marble, but it will cost you much less.

It is quite possible to make an acrylic stone at home. To do this, you need to purchase a mineral filler, a ready-made mixture for pouring (compound) and resolve the issue with the form. From acrylic, you can make not only a countertop or some decorative elements, but also a window sill, for example.

In any case, you will need a mold for pouring, lubrication. For casting, a mixture of filler (70% of the total mass), acrylic resin (25%) and hardener (5%) is used. As a filler, you can use stone chips. Before complete solidification, at least 2 hours should pass. After removing the artificial stone from the mold, it can be sanded if necessary and varnished.

Acrylic stone surfaces do not tolerate caustic chemicals and increased mechanical stress.

How to make flexible stone

If you still did not know what a flexible stone is, get acquainted. It is a thin elastic material that can imitate the surface of natural stone or wood and is suitable for interior and exterior decoration. The undoubted advantage of this material is the ability to take any shape. They can decorate not only walls, but even pieces of furniture.

Flexible stone, in addition to decorative properties, is easy to maintain, incombustible, immune to weather changes and temperature extremes.

To make a flexible stone, you will also need a flat surface with sides. The main material is fine-grained stone chips or coarse river sand. You can tint a flexible stone with acrylic dye, but professionals recommend using metal oxide for tinting.

Before starting work, the fiberglass is lightly fired. This treatment removes paraffin deposits from the surface, which will interfere with good adhesion.

Further, everything is very simple: a ready-made pebble mixture is applied to the surface of the fiberglass and left to dry completely. Cut the finished material into pieces of the desired shape. If there is a need to mount the stone on particularly difficult surfaces, it is preheated with a building hair dryer.

There is another, no less simple option for preparing a flexible stone. A sheet of glass is used as a working surface. It is rubbed with wax, a composition of sand or crumbs on polyester resin is applied to it and rolled on top with fiberglass. After solidification, the material is separated from the glass.

How to fix artificial stone on the wall

For the installation of artificial stone, there is no need to carefully level the wall. There is only one caveat: an uneven wall will “eat” too much glue, so it’s better, of course, to prepare it. In addition, if you decide to cover the wall with a flexible stone, then after all it should be even. When using artificial cement stone, the wall surface must be reinforced with a layer of plaster with a reinforcing mesh, it will help withstand the increased load. For rooms with high humidity, an additional liquid waterproofing is applied under the laying.

Laying stone is similar to installing wall tiles. The principle is the same: an adhesive solution is applied to the wall with a notched trowel and a stone is attached to it. If you have a lot of artificial stone of various shapes, it makes sense to first lay out the pattern on the floor in order to clearly imagine the sequence of elements. After laying, the seams are filled with mortar or grout.

A detailed step-by-step process of simulating masonry on a wall is described in this video:

We told you what decorative artificial stone is made of. Have you had to use artificial stone in decoration or make it yourself? Share your experience in the comments!

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?

Four days ago I ordered a Revolts heating kit for our dacha. I'm going to pick up tomorrow...

If the apartment is ready, then why doesn’t Buzova broadcast to the whole world about moving and living ...

Like 10m. Enough tape for 1.5m of fence?!

This is most likely an Internet modem like yota. And, I remember, they used both polarizers ...

Wicker fence is a waste of time and money. When we were equipping the site, we bought: up to ...

6 acres is a fairly small area, so there were no problems with zoning ...

Those who usually suck at life really do not understand a lot of things. And in general they regretted ...

That blogging shit again... Suck on!!!

I just can’t understand: where do juvenile cockerels and swallowers get such incomes from? Who encourage...