The need to pump out water can arise for various reasons. For example, you have a leak or need to pump liquid from one container to another in a short time. Not every home has a pump for pumping out. This device costs from 2 thousand rubles, and if it is not constantly needed, then there is no point in buying it. But just in case, you need to prepare an alternative option. Indeed, even an ordinary drill or screwdriver can be turned into a pump for pumping out. To do this, you just need to make a small fixture that can wait in the wings without taking up a lot of space in your workshop. How to do this, showed the author of the YouTube channel Musiy4uk. This is a very simple master class, and it will not be difficult for you to repeat it.

Read in the article

- 1 What you need to prepare for a homemade pump

- 2 Algorithm for assembling the pump head

- 3 How to make a manual pump for pumping water

What you need to prepare for a homemade pump

So, to turn a drill into a pump, you need to make a special nozzle. To make it, you need an ordinary plastic sewer pipe.

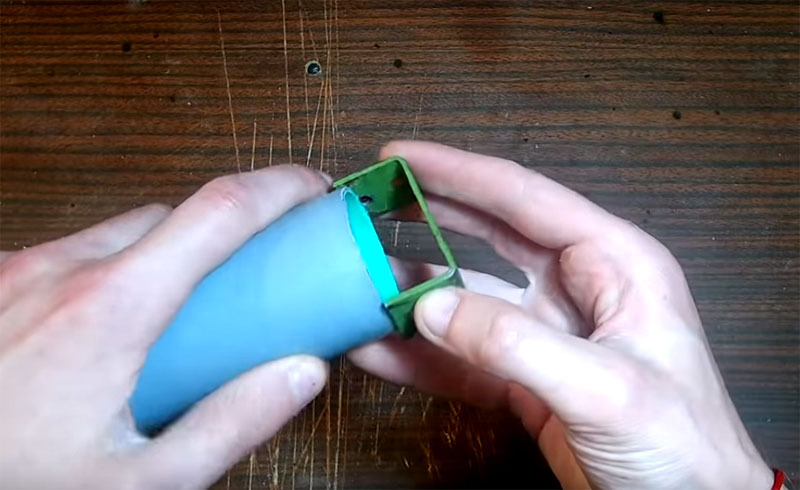

You will need three plumbing parts: a tee with seals, a piece of pipe about half a meter long and another 20 cm long. In addition to them, you will need one plug for a pipe of this diameter, a hose fitting, a metal stud that can be inserted into the drill clamp, and a piece of metal to make the impeller. You also have to find or make a U-shaped part that can be fixed to the pipe through the side holes.

Algorithm for assembling the pump head

So, the sequential build procedure is as follows:

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comTo drain the water during the pumping process, you will need to connect a hose to the pump. This is what a fitting is needed for.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comNow you can start assembling the pump housing. In the tee that you have prepared, there must be gaskets - rubber or silicone rings.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

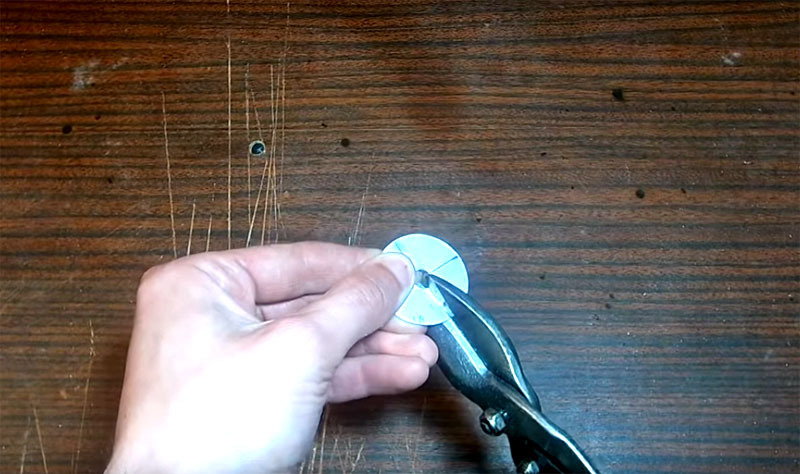

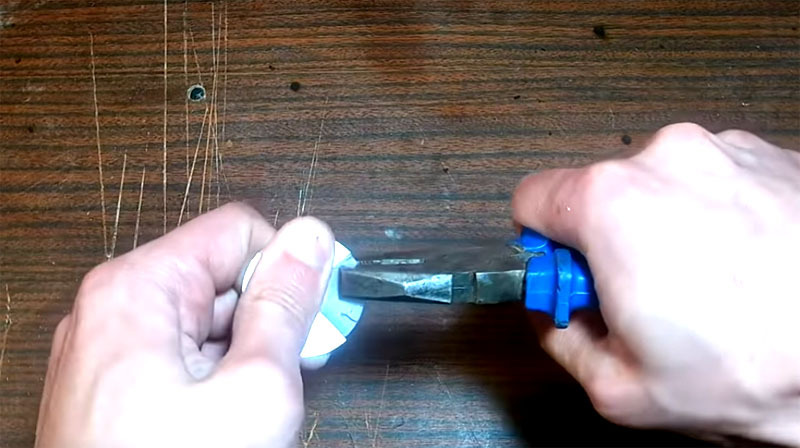

PHOTO: YouTube.comIn order for water to move inside such a device, a mechanism is needed that would set it in motion and make it rise up and enter the hose. A metal pin and an impeller (screw) will perform this task.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comHow long should the hairpin be? At least half a meter, so that after assembly, the part with the impeller will be slightly lower than the tee. Now you can connect the bit to the drill. The only problem here is to firmly fix the sewer pipe to your tool.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comAs you can see, the device has a very simple design. If you have a cordless screwdriver or drill, then you can use such a pump literally anywhere and not be connected with a power source, which is very important. The pumping speed will not be very high, but the performance disadvantages are fully compensated for by your savings on buying a real pump.

As already mentioned, you can make such an attachment in advance and keep it in case of an emergency. Manufacturing costs are minimal. We must admit that in order to start this nozzle, you will need to tinker and wait until the water fills the system. But the rest of the device is quite effective.

How to make a manual pump for pumping water

Using the same materials, that is, sewer pipes, a hand pump can also be assembled. It will come in handy on a fishing boat or in the bathroom in case of an accidental water spill. How to do it is shown in this video:

How efficient do you think a drill pump will work? Share your opinion about this master class in the comments. If you know about more productive homemade products, write to our editorial office.