CONTENT

- 1 Advantages and disadvantages of using such devices

- 2 Types of drill bits for cutting metal

- 3 Structures and how they work

- 4 How to apply correctly

- 5 Where is it more profitable to buy a drill bit for cutting metal, price overview

- 6 Other drill bits used for repair needs

Advantages and disadvantages of using such devices

Drill bits, as well as other technical devices, have advantages and disadvantages that determine their purpose and use.

The advantages of such devices include the following indicators:

- the quality of the cut (evenness and absence of burrs) of the processed material is much better than when using a "grinder" (angle grinder);

- the ability to use on workpieces of any shape and configuration;

- convenience and simplicity when performing work;

- increasing the functionality of the drill and screwdriver;

- ease of maintenance and repair;

- increase in labor productivity when performing work with their use.

The disadvantages of such products include:

- the thickness of the processed material is limited, which is associated with the power of the electric tool and the technical characteristics of the nozzles themselves;

- the need for work skills, otherwise it is impossible to achieve cut quality;

- when working, it is necessary to use both hands, which is not very convenient when performing some assembly operations: work at height or with thin-sheet workpieces.

Types of drill bits for cutting metal

The industry produces various types of drill bits used for grinding and polishing, angle drilling and sharpening, processing livestock and poultry, and cutting sheet materials.

Various devices are used for metal cutting, the most popular of them are: "Cricket", "Scissors", "Steel beaver" and "Jigsaw".

Cricket drill bit

Cricket is a versatile device that is, in fact, a nibbler. The range of use of this device is quite extensive.

"Cricket" is used for cutting:

- sheet black and stainless steel, copper and aluminum, as well as sheet plastic;

- in horizontal and vertical planes, as well as for performing an internal cut;

- corrugated board and metal tiles, as well as other thin sheet materials (tin, food foil, etc.).

When using the Sverchok nozzle, it is necessary to follow the manufacturer's recommendations for the type and thickness of the processed material, measured in mm. And also keep in mind that the rotational speed of the electric tool must be at least 1500 and not more than 3000 rpm.

Drill attachment for metal cutting "Scissors"

"Scissors" are the most famous and common type of attachments used in metal processing.

This device is used for cutting sheet metal without profile bends or with large radius waves. It is used for curly carving with small cut radii.

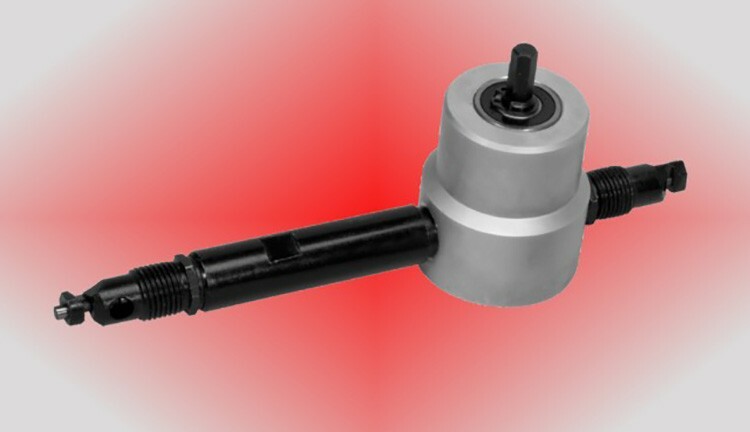

Steel beaver attachment

In terms of its design and functionality, the type of “Steel Beaver” nozzles is similar to the “Cricket” type, with the only difference that this device can be used when processing workpieces of greater thickness.

This feature somewhat increases the capabilities of this type of device, otherwise they are similar.

The attachment rotates 360 ° around the cutting shaft, which is very convenient when performing work.

Drill bit "Jigsaw"

This type of device is used more for processing wooden surfaces. With their use, you can cut boards and other thick lumber, as well as cut complex patterns.

For metal processing using the "Jigsaw" attachment, special files are inserted into it, and the work (screwdriver) in tandem with this attachment resembles the use of a reciprocating saw, which is a type of manual electric tool.

Structures and how they work

The principle of operation of the nozzles used for cutting metal is to convert the rotational motion of the electric motor shaft into the translational motion of the cutting mechanism.

Drill bits for metal cutting are fixed in the chuck and brought into operation using the start button (key) of the tool used.

IMPORTANT!

When using attachments for cutting metal, the rotational speed of the drill (screwdriver) must be at least 1 500 rpm, otherwise the quality of the cut is reduced, the cut may jam material.

In devices such as "Cricket" and "Steel beaver" the work of the cutting mechanism is similar to the principle of operation office punch: when a thin striker punches holes of small diameter along the entire length of the cut surface. The translational movement along the cut line gives the force created by the person.

In the "Jigsaw" type attachment, the cutting blade moves "back and forth", and the force on the cutting site is given by a person.

The principle of operation of devices of the "Scissors" type is similar to the action of simple scissors, with the only difference that in the attachments one of the cutting blades can be fixed rigidly, and only the second can be movable.

Structurally, all attachments consist of:

- corps - which is the basis of the structure, in which the cutting parts and the mechanism for converting rotary motion into translational motion (gearbox) are located;

- cutting elements - canvas, firing pin or knives;

- shank - which is a connecting element between the gearbox and the chuck of the drill (screwdriver);

- nodes and components, providing ease of operation (handles) and reliability of fastening (fasteners). They may be different for different devices or not at all.

How to apply correctly

Drill bits for metal working should be used in accordance with the manufacturer's instructions for use. The instructions define a list of materials available for processing by one or another device, and their parameters.

General requirements for correct use can be formulated as follows:

- A drill (screwdriver) must have the necessary technical characteristics (power, rpm) to perform metal cutting operations and be technically sound.

- The nozzle is installed in the chuck of the used electric hand tool and is securely fixed.

- If necessary, handles and additional fasteners are installed - if such are provided by the design.

- When performing complex work, devices are prepared that ensure the performance of the required operations - brackets for a stationary installation of a drill and other structural elements.

- In the process of cutting, it is necessary to monitor the progress of the operation; in case of metal biting, it is necessary to turn off the tool and eliminate the cause that caused it.

- Perform work in protective clothing and using personal protective equipment.

- After completion of the work, it is necessary to remove the formed shavings, clean and put the tool in storage.

Where is it more profitable to buy a drill bit for cutting metal, price overview

Drill bits used for cutting metal are a special item not found in an ordinary store of building materials or tools located in an accessible proximity to consumer.

The most convenient way to purchase these products is to find the necessary device on the Internet and determine with the company the manufacturer of this device.

After that, you can go in two ways:

- Find a dealer of the manufacturer's company and contact there for more detailed advice and purchase of the required model.

- Use the search on the Internet and find a company directly in the network that has the required device in the range of goods sold.

The price of various models of attachments used in this article and sold through the Internet resources is shown in the following table:

| Item No. | View | Model | Cost, rub. | Online store |

| 1. | "Cricket" | "Anchor" | 1 329 | "220 volt" |

| 2. | SPARKY 181874 | 2 010 | "All tools" | |

| 3. | "Anchor" | 1 309 | "BiGam" | |

| 4. | "Scissors" | MALCO TSMD EV | 13 990 | "All tools" |

| 5. | EDMA | 14 000 | "House and Dacha" | |

| 6. | MALCO TurboShear TSV1 EV | 19 300 | "All tools" | |

| 7. | "Steel beaver" | "Grand Line" (box) | 1 850 | "Grand Line" |

| 8. | "Grand Line" (blister) | 1 450 | "Grand Line" | |

| 9. | "Grand Line" (box) | 2 099 | "Petrovich" | |

| 10. | "Jigsaw" | Black & Decker MTJS1 | 1 649 | "OZON" |

| 11. | OMNI-JS Fixtec AEG 440715 | 4 385 | "All tools" | |

| 12. | Rovus "Rocket" | 1 999 | "Top-shor" |

Other drill bits used for repair needs

As mentioned above, the industry produces various types of nozzles, in addition to those discussed in this article.

The presence of various devices significantly expands the functionality and demand for drills and screwdrivers, and also eliminates the need to purchase a special tool designed for highly targeted use.

With the help of special attachments you can:

- sharpen drills and drilling at a certain angle;

- grind and polish surfacesmade of various materials - metal and wood, natural and artificial stone, as well as plastic;

- pluck poultry and process skins pets for further use or for slaughter.

Which attachment to choose and where to buy it is up to each user independently, depending on the need for these devices and their location.

An electric drill and screwdriver is a highly functional tool that everyone should know about!

Video of using the nozzle for cutting thin sheet metal - "Cricket":