At the moment, it is possible to find a large number of insulating materials, with different parameters and features in the installation. Basalt or glass mineral slab is often used, as the most comfortable and reliable during installation. Rockwool Light Butts is considered one of the most popular slabs.

Features of mineral wool boards

Mineral wool is a material that is made from molten volcanic rock, blast furnace slag or glasses (passed through a centrifuge to pulp and mix with phenol-formaldehyde resins).

Important! Due to the technical characteristics of Light Butts Rockwool mineral wool boards and ease of use, miniplates hold leading positions in the market of building materials used to insulate the roof, facade.

The advantages of using mineral wool slabs include the following:

- duration of operation (terms of use will be 50 years);

- good parameters of heat and noise protection;

- high vapor permeability;

- adequate price;

- comfort of marking, cutting, installation;

- small specific weight, which allows you to remove the load on the structure;

- high density, strength;

- bio-, fire resistance;

- unattractiveness for attacks by rodents and other pests.

The disadvantage of mineral wool will be that the material is vapor-permeable, water vapor will pass between the fibers. Therefore, it is important during installation to allow the vapors to provide an outlet to the outside so that they do not accumulate in the slabs: the wet mineral wool will not dry out, it will have a high thermal conductivity. For example, polystyrene or polystyrene is almost completely vapor-tight.

Specifications of Light Butts Rockwool

Rockwool Light Butts Scandi belongs to an environmentally friendly fiber insulation with increased energy efficiency. They have good elasticity and vapor permeability, low weight. They will also keep their own qualities unchanged over a long period of time.

The main advantages of Light Batts:

- Due to the fibrous structure, the dwelling is firmly protected from heat loss and excessive noise.

- Natural base and compliance with sanitary safety standards.

- Biostability and chemical inertness. The material is not subject to rotting, insect attacks.

- The springiness of the slabs simplifies, speeds up the installation, excludes falling out of the auxiliary structures. Stone wool of this brand will not slip, which ensures a high fit, the room is protected from drafts.

- Ease of cutting, solid edges, elastic, uniform structure.

- It can shrink with further restoration of its shape.

- Low weight bearing.

- A good indoor climate is provided due to the high coefficient of thermal conductivity and fibrous structure. In this aspect, Rockwool is more effective than polystyrene.

- Ability to remove moisture. Light Butts miniplates are covered with moisture-repellent compounds, during the correct installation of the vapor barrier and ventilation, Rockwool insulation will not accumulate moisture. These mineral wool boards can be exposed to a strong moisture load or used without the protection prescribed by the rules for building structures (sudden penetration of condensation will not cause harm).

- Fire resistance. The lower limit of heat resistance will be 250 degrees, fibers - 750.

Important! A characteristic advantage during the use of Light Butts Mineral Plates is their combined structure with a hard outer layer, soft and lightweight, which adheres to the treated coating.

Dimensions (edit)

Light Butts Extra is a unique heat-insulating material that restores shape and structure. The packaging will take up 70% less space than when the boards were unpacked. This is due to the fact that the material is in a vacuum, the air is completely removed. As a result, thermal insulation is easy to move, even in small cars. For the comfort of movement, the material is made in 2 sizes:

- standard;

- XL.

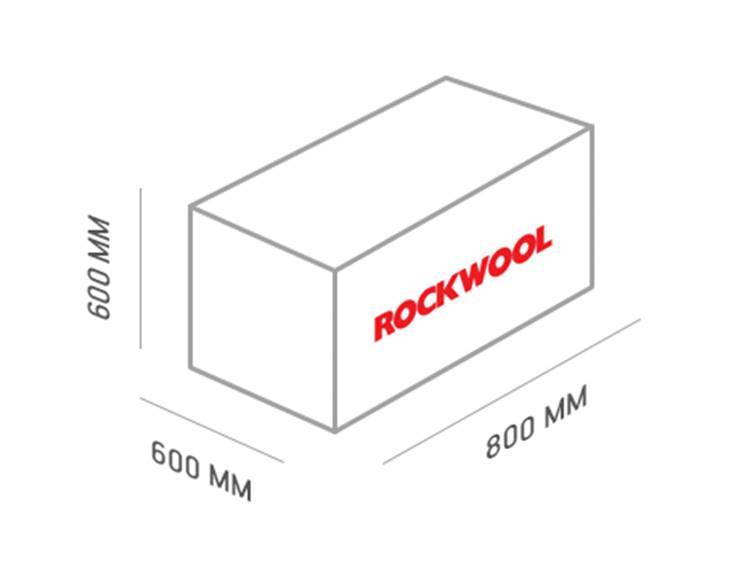

In 1 case, miniplates have the following parameters:

- length - 0.8 m;

- width - 0.6 m;

- thickness - 0.05 or 0.1 m.

XL insulation in large sizes:

- length - 1.2 m;

- width - 0.6 m;

- thickness - 0.1 or 0.15 m.

1 package contains 5, 6, 12 pcs.

Frame walls (inclined, vertical), attics, ceilings, partitions are insulated with mineral wool slabs. Their density is 30 kg per cubic meter. m, the thermal conductivity coefficient is 0.035-0.040 W per mK. Unlike ordinary mine slabs, in Rockwool the fibers are arranged horizontally and vertically. This is why they have such an elastic structure. Recommended temperature indicators for use - up to +250 degrees. When heated more, the binder evaporates. As a result, the terms of use of the material are reduced.

Installation work

Insulation of the facade of the dwelling with mineral wool begins from the bottom of the wall, is performed on a pre-installed profile. For fixation, 2 methods can be used, recommended to be carried out in a complex manner:

- glue, during which the plates are fixed to the coating using special compounds (for best results, it is recommended to use Rockglue);

- use of dowels with large locking washers.

The glue is applied to the coating of the mineral slab with a layer of 0.3-0.4 cm with a notched spatula, then the slab is pressed against the wall, and after 2 days it is possible to start fixing with dowels.

Important! Reinforcement is mandatory, for which a stack of steel or glass is used. When the applied layer of plaster does not exceed 1 cm, then glass mesh is used; in other situations, it is required to choose steel products.

Reinforcement of the insulation is carried out at the same time with the fixing of the mineral plates with the help of dowels. For reliable fastening, in addition to anchors, a special putty is used, which, after drying, is necessarily treated with a primer.

The final stage in the installation of Light Butts miniplates will be plastering using facade insulation under the plaster. Often in such situations, decorative facade plasters are chosen, applied in a thin layer. This will help to eliminate additional stress, add strength, increase the service life, provide great color, textured opportunities when creating an architectural style of a home.

To improve the sound and heat insulation parameters in the home, there are a large number of methods and materials. However, one of the most effective and comfortable is considered to be facade insulation with the help of Light Butts miniplates. Before starting work, it is important to familiarize yourself with the step-by-step guide, the technical parameters of the material.