For those living in private sectors and for summer residents, the issue of installing a water pump is often very relevant. Its purpose can be varied - heating system, water supply, pumping water from the cellar. If the pump is required for continuous operation, a stationary one is installed. But what if pumping is required from time to time? In this case, it makes no sense to purchase expensive equipment. The answer to this question was found by the author of the YouTube channel Sergei.

Read in the article

- 1 What meter can be used to make a water pump

- 2 Dismantling the water meter for modernization

- 2.1 Removing unnecessary parts of the meter

- 2.2 Assembling the meter-pump in the reverse order

- 3 Final pump assembly and first performance tests

- 4 What else can be used as a pump drive for water

- 5 Features of the manufacture of mechanical pumps

- 6 Final part

What meter can be used to make a water pump

In fact, it does not matter which company meter will be used for today's homemade products. However, despite the fact that any meter can be used as a pump, with modern models difficulties may arise in terms of connecting a drive to them. Therefore, it is better if an old-style water meter was chosen as a "donor".

Dismantling the water meter for modernization

Depending on the model, the top cover can be secured with a plastic clamp or threaded connection. In our case, this is the second option, for disassembly of which the cover simply needs to be unscrewed.

Removing unnecessary parts of the meter

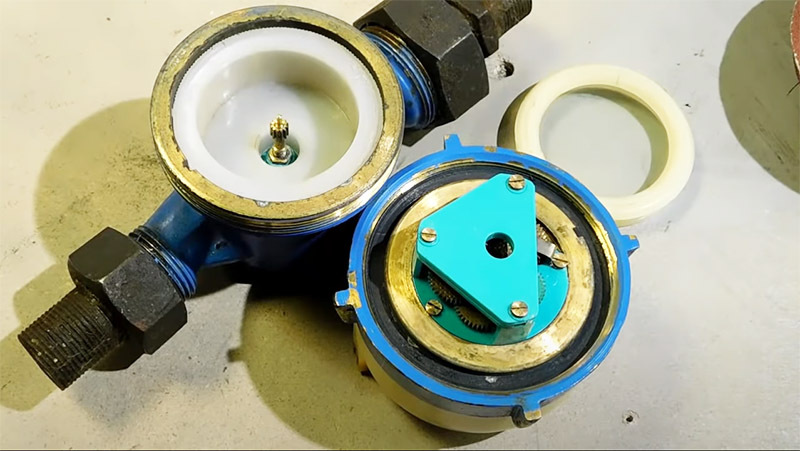

Having pulled out the mechanism itself with the drums, on which the numbers are applied, from the inside, you can get to the rubber ring in the lid. This gasket covers the 4 screws that secure the glass. First, remove the seal, unscrew the screws and remove the glass - for further work it will not be needed. But the rubber gasket must be put in place.

The counting mechanism itself also needs to be removed. In fact, there should be a brass disc, from the bottom of which the gearbox is fixed. This gearbox is used to transmit torque from the impeller shaft installed at the base of the meter.

At the same time, the condition of the impeller should be assessed, which will be the main unit providing the pumping capacity of the water pump. The impeller is located at the bottom of the meter under a plastic sheath.

Assembling the meter-pump in the reverse order

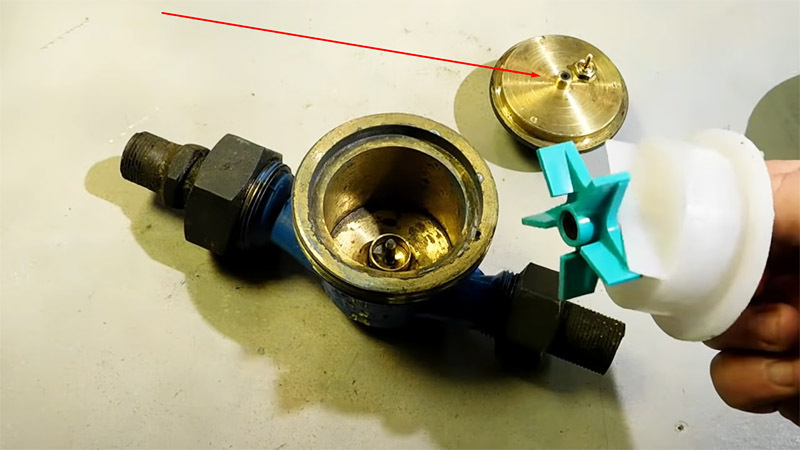

Now that all unnecessary parts have been removed, you can assemble the resulting device in reverse order. It can no longer be called a water meter, however, it has not yet become a full-fledged pump. After all, a piece of metal itself is not able to pump water, which means it's time to think about what can be used as a drive for it.

Final pump assembly and first performance tests

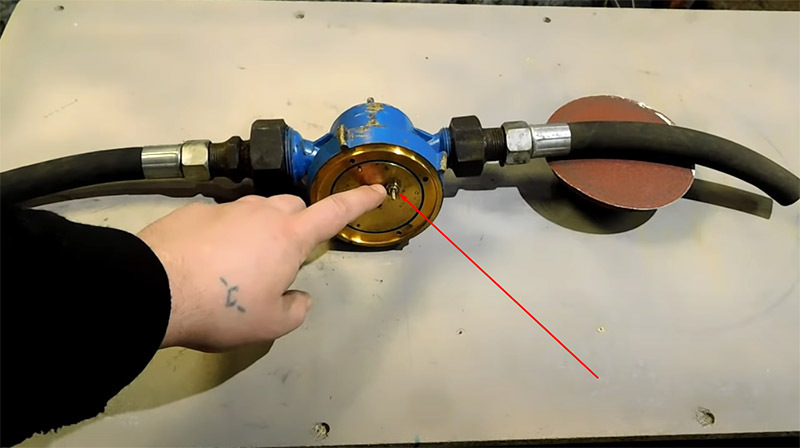

When the pump body is assembled, it is necessary to connect two hoses to it - for the water inlet and outlet. To check, it is not necessary to wind them using various adapters, etc. It can be easier if the hoses are pulled over the pipes.

On the upper disc, which, after removing unnecessary parts, was in direct access, you can see a small spindle. It is he who will be the driving one. Now it is time to think about which equipment torque will be transmitted to the pump. The simplest solution to this issue is to use a simple screwdriver. It will be enough for verification. The spindle must be tightly clamped in the chuck, one of the hoses must be lowered into a reservoir with water, and an empty basin under the second.

What else can be used as a pump drive for water

If you have free time, you can assemble a kind of stationary mini-pump. To do this, it will be necessary to fix an upgraded water meter, an electric motor on the platform and think over how to organize the transmission of torque. It can be a direct drive, as in the case of a screwdriver or drill, or a belt drive, using pulleys.

Features of the manufacture of mechanical pumps

Russia is a country famous for its non-standard approach to everything our craftsmen undertake. So it is with similar pumps. We bring to your attention several photo examples of such installations, which hardly anyone else would have thought of abroad.

Final part

Perhaps many will now say that such homemade products are a waste of time. However, it should be argued that such modernization cannot be called useless. Indeed, in addition to the fact that instead of a landfill, the meter is sent for alteration, after which it is used for a long time, this is already not bad. In addition, a water pump on the farm will always come in handy. After all, it can be used even for arranging the water supply of a private house, not to mention pumping liquids, for example, from a large container into buckets. In addition, we will tell you a secret: the plastic of the impeller is oil-resistant, which means that the pump can be used to pump fuel and lubricants.

We hope that today's master class on making a liquid pump from an old water meter will be useful to home craftsmen. If a respected reader suddenly has questions on today's topic, you are welcome to discuss with them below. HouseChief editors will be happy to answer each of them. And it is possible that other readers who are competent in this matter will join the discussion. There you can also express your personal opinion on whether it is worth doing such alterations at all. If you liked today's article, do not forget to rate what you read. Your opinion is extremely important to us. Take care of yourself, your loved ones and be healthy!