Construction is very popular now timber houses and rounded logs. The tree has a lot of advantages (durability, ease of processing, strength, etc.), due to which it is so in demand in construction. but wood is subject to the formation of various defects that must be eliminated as quickly as possible in order for it to retain its characteristics for a long time. In today's HouseChief review, we will talk about old-fashioned and modern methods of sealing cracks in logs and beams.

Read in the article

- 1 The need to seal cracks in the timber

- 2 Defect sealing methods

- 2.1 Sawdust and PVA

- 2.2 Sliver, or stub

- 2.3 Wood putty

- 2.4 Acrylic sealant

- 2.5 Epoxy resin

- 2.6 An effective "old-fashioned" way

- 3 A few words in conclusion

The need to seal cracks in the timber

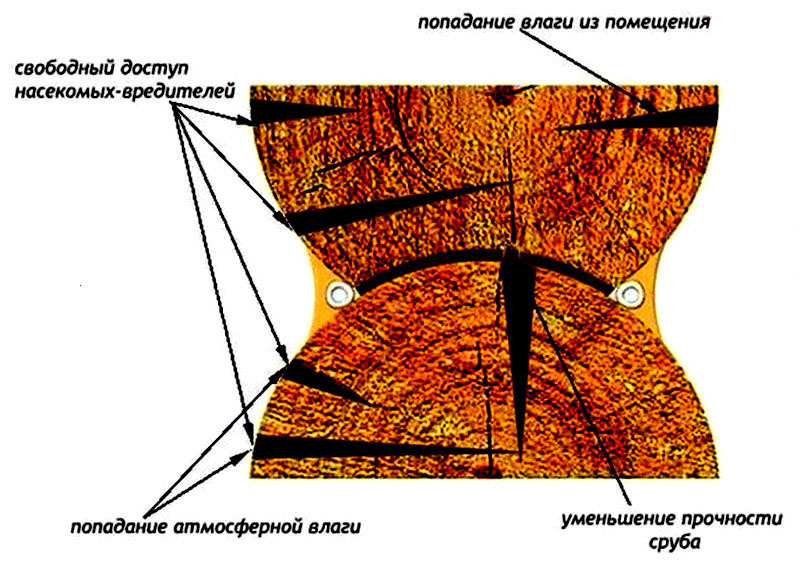

Cracks in a bar or log can appear for a variety of reasons. This happens when the rules of transportation, storage are violated, due to improper processing, etc. Any defect in the surface of the wood contributes to the easy penetration of water into the lumber. Since the core cannot quickly release moisture, the likelihood of the formation of putrefactive processes increases significantly. In addition, cracks become a haven for insect pests and a place for heat leakage. Therefore, in order to exclude all these unpleasant moments, it is necessary to promptly eliminate any wood defects.

Defect sealing methods

Timely measures taken to protect wood will prevent moisture from entering the material, will extend its service life and, accordingly, will have a positive effect on the strength of the structure. Various materials are used to eliminate defects, which must adhere well to cracks and provide excellent tightness. However, before processing, the surface must be cleaned of dirt, dust and chipping. Also, the processing method must be chosen depending on where the defect is found: outside or inside the house.

Sawdust and PVA

The method of sealing cracks in wood, common among specialists, is the use of a moisture-resistant mixture of sawdust and PVA glue. Regular shavings are not suitable because they are coarse. Sawdust is diluted with glue to a homogeneous state and consistency wall putty. The resulting mixture is used to fill the crack with a rubber spatula. After drying, a second layer is applied, which must also dry and sand with fine-grained sandpaper.

You can also make a mixture of sawdust and wood glue. Such a composition will have a positive effect on the moisture resistance, strength and durability of lumber. The composition is applied in excess, and after drying, cut off the excess and grind with a fine-grained abrasive.

This option is suitable for both outdoor and indoor use.

Sliver, or stub

Another way to close up significant cracks in the timber, which has been used for a long time, is a chip, or a plug. To do this, you need to take the bar and sharpen it under the wedge along the entire length. Moisture-resistant PVA glue should be applied to the chips and crack, after which the workpiece should be hammered in with a mallet. When driving a wedge, you should not apply significant effort, then the repair site can be additionally treated with a mixture of sawdust and glue.

Wood putty

The most common, but ineffective way to seal cracks in a bar or log is to use a special putty for wood. It is used to repair wood inside a building and seal defects no more than 3 mm deep. If this value is exceeded, the putty may crack and peel off from the base during shrinkage. The mortar is applied with a spatula, and after drying, the place of repair is sanded, and, if necessary, tinted to match the color of the wood.

Related article:

What are wood putties: leading manufacturers, the difference in composition, advice on choosing a suitable option for indoor and outdoor work, the procedure for cooking with your own hands and the sequence of application to the base.

Acrylic sealant

The use of acrylic-based facade sealant is a more modern way to seal cracks in logs and beams. It is distinguished by high adhesion and environmental safety, shrinks up to 25% without loss of technical characteristics. Before treating cracks and crevices with a sealant, the base must be thoroughly cleaned of dust and dirt. If the depth of the defect is more than 5 mm, then a polymer or silicone tourniquet is preliminarily laid in the split. The opinion of experts about the use of sealant is ambiguous: some argue that it is effective, while others that acrylic does not allow the tree to "breathe", and as a result, it forms at the place of processing. mold and fungus.

Epoxy resin

Epoxy resin - a two-component compound characterized by good viscosity, fluidity, high adhesion and penetrating power. It completely fills the crack and practically does not shrink, and when dry, it not only protects the wood, but also performs a reinforcing function. As a result, the epoxy resin prevents crack growth and strengthens the structure.

An effective "old-fashioned" way

Our ancestors built wooden houses that were able to last more than 100 years, and they knew a lot about this business. For centuries, they used moss to seal the joints between logs and cracks in the wood, which grew in all the surrounding forests. This plant has low thermal conductivity and serves as additional thermal insulation.

Caulking of seams and cracks was performed with well-soaked and squeezed moss. If the plant was dry, then it was soaked for 30-60 minutes and squeezed well. After that, the resulting mass was rolled into rollers and pushed into cracks and crevices using a wooden spatula. Also for this they used a special wooden spatula and a mallet.

It takes about 3 days to dry the caulk, during which it increases in volume up to 30%. As a result of such processing, the smallest cracks and cracks are filled and clogged. At the same time, the filler and wood breathe, which means that the appearance of fungus and mold is excluded. Excess moss is cut off, and the caulk itself looks organic on a wooden frame.

A few words in conclusion

Unsealed cracks in logs and beams can lead to weakening of the structure, deterioration of the thermal insulation characteristics of the structure, the appearance of mold, etc. In today's review, we have presented the most basic ways to seal wood splits and we hope that this information will be useful to you, and you will share it with your friends.