Many are interested in the question: isolon, what kind of material is it, what is the scope of its application. Due to its high performance characteristics, it is used everywhere, starting from thermal insulation works in the process building a house and ending with the manufacture of decorative elements. We offer you to get acquainted with the features of this material, as well as learn how to independently make an original lamp for your home.

Read in the article

- 1 Izolon: what kind of material is it, the main scope of its application

- 1.1 Izolon: what is it, its scope

- 2 Features of production

- 3 Properties and characteristics depending on the type

- 3.1 PPE and IPE

- 3.2 Foil on one or both sides

- 3.3 Uncoated products

- 3.4 Covering and self-adhesive material

- 4 Isolon dimensions

- 5 Advantages and disadvantages

- 6 Choosing an isolon for insulation

- 7 Thermal insulation material installation technology

- 8 Crafts from izolona do it yourself

- 8.1 Workshop on making a lamp in the shape of an owl from an isolon

- 8.2 Lamps in the form of flowers from Isolon

- 8.2.1 DIY rose lamp from isolon: master class

- 8.2.2 Peony lamp from isolon: video instruction

- 8.3 Workshop on making a lamp in the shape of a doll from izolon

- 9 How much is Isolon - an overview of prices per square meter

Izolon: what kind of material is it, the main scope of its application

To determine the possible area of use of the isolon, one must clearly understand what this material is. It has high performance due to its structure and appearance.

Izolon: what is it, its scope

Izolon is made of polyethylene foam. The porous structure of the material provides high thermal insulation characteristics and gives good elasticity. Having figured out what an isolon is, it is worth clarifying the possible field of application. The manufacturer offers material that is in demand when:

- performing thermal insulation works. It allows you to insulate various substrates. Due to its shape, it is widely used for thermal insulation of engineering communications;

- creation of thermo-reflective screens. The good reflectivity of the foil film with low thermal conductivity allows it to be placed behind heating radiators or behind heating devices;

- organization of soundproofing. Allows you to protect the interior from external noise and vibration. During construction, it is used as damping spacers between the parts to be joined;

- device hydro- , vapor barrier. For some premises, this option is the only one;

- thermal and noise insulation of vehicles;

- the manufacture of freezers, refrigerators, air conditioners and a number of other climatic technology;

- the production of sports, tourist clothing and footwear, the manufacture of toys, interior items.

Features of production

Isolone production is carried out in several stages:

- mixing, during which granular polyethylene, foaming agent and a number of "crosslinking" agents are mixed in one container;

- extrusion, during which the prepared polymer mass is heated and then melted. Also at this stage, the sheets are formed;

- foaming. The formed sheets on the conveyor net are sent to the oven. Due to the effect of high temperature, the foaming agent is activated, which contributes to the appearance of a large number of pores in the material.

If a foil-coated isolon is made, at the last stage, a thin aluminum foil is additionally glued to the surface of the finished material.

Properties and characteristics depending on the type

The properties and characteristics of an isolon directly depend on its type and determine the possible scope of application. Before giving preference to a particular variety, it is worth familiarizing yourself with the options available.

PPE and IPE

PPE - cross-linked polyethylene foam. During the production of this variety, the components change their state at the molecular level. There are transverse ligamentous and reticular molecular bases. Due to this, the material better resists the effects of aggressive substances, has increased moisture resistance, which significantly expands its possible scope of use.

NPE - uncrosslinked polyethylene foam. This material has practically no bonds at the molecular level. It is a substance with a closed cell structure, filled with gas. During the production process, at the stage of foaming during the heat treatment of the feedstock, the mass is filled with carbon dioxide. Penetrating into the large pores characteristic of this variety, it gives the canvas the required properties.

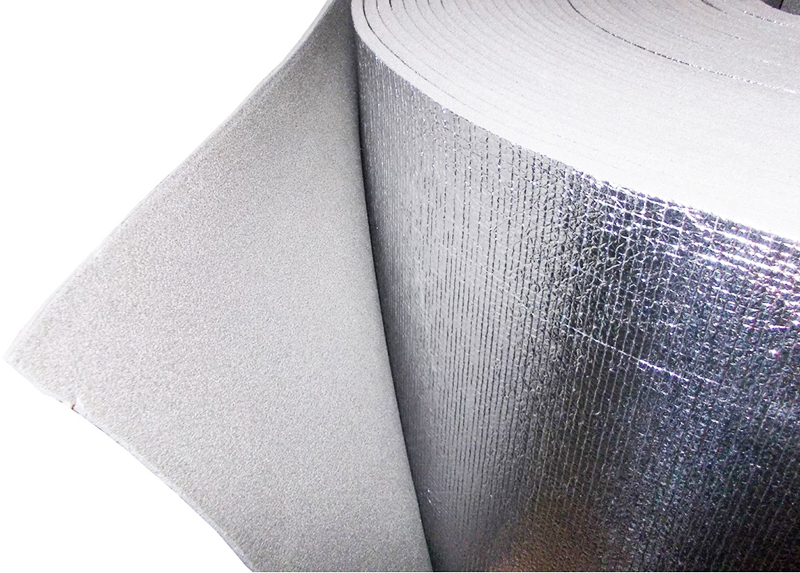

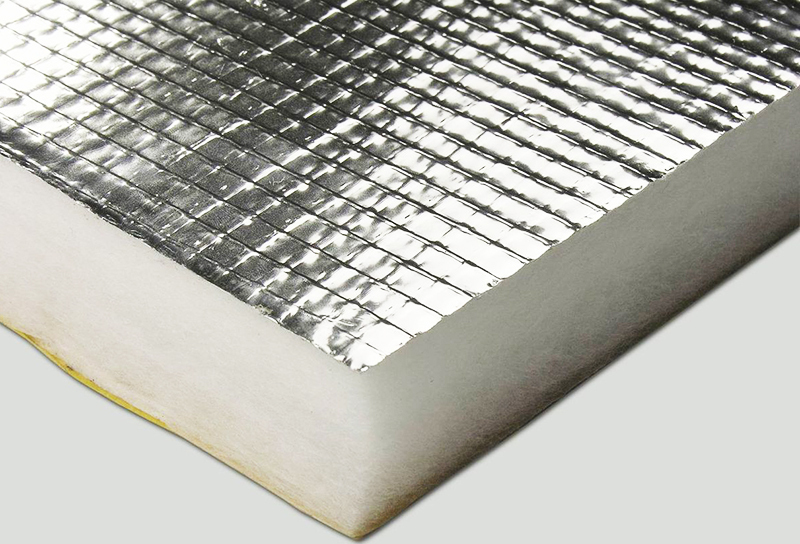

Foil on one or both sides

In terms of its structure and composition, this variety is no different from the classical one. However, it has a foil film with a thickness of 10 - 100 microns on one or both sides. For its manufacture, aluminum or other metallized composition can be used.

Due to its high performance characteristics, foil-clad material is used when performing work inside and outside the building. The choice of a variety depends on the application. So, for the device of the floor covering, an isolon with a heat-reflecting film is chosen. During installation, the sheet is positioned so that it is on top.

Uncoated products

The performance characteristics of this variety are relatively low. The absence of additional coating impairs its properties and reduces the cost. Due to its availability, it is used in various fields.

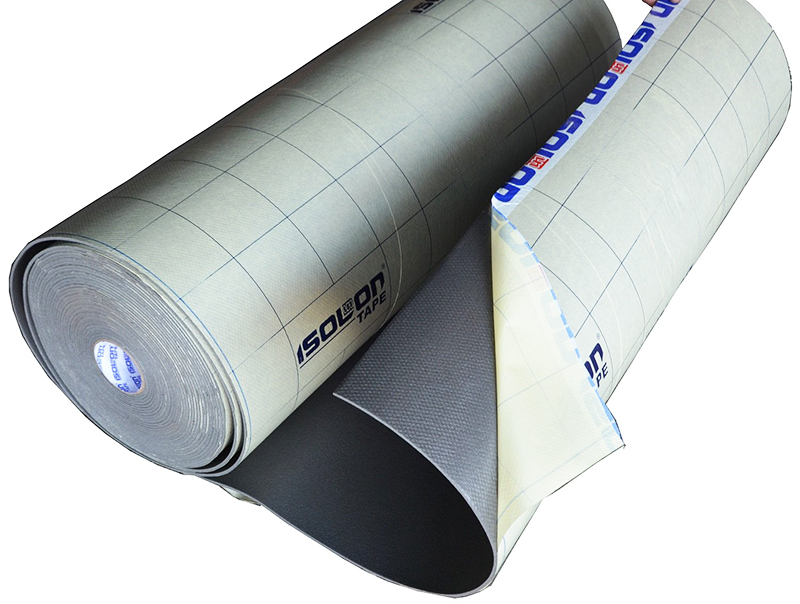

Covering and self-adhesive material

The covering material allows the formation of an airtight coating. It is glued to the base with glue. Sheets are stacked end-to-end or overlapped, if the thickness is relatively small. With the help of construction tape, the tightness of the joints is ensured.

Self-adhesive isolon is attached to the base immediately after the protective film is removed. A special adhesive applied to the surface of the material will allow it to be fixed in the desired position. Self-adhesive foil isolon is especially popular.

Isolon dimensions

When choosing the size of an isolon, the scope of its application must be taken into account. If the material will be used for floor insulation, it is worth choosing a variety that has a thickness of up to 5 mm. The soundproofing of the roof is carried out using sheets with a thickness of 5 - 10 mm. For the installation of interfloor floors, products with a thickness of 10 - 30 mm are required.

Attention! Manufacturers offer izolon, the thickness of which reaches 50 mm.

The length of the sheets can vary in a wide range: from 2 to 300 m. The width ranges from 0.5 to 2 m. The dimensions of the slabs may also vary. On sale you can find material measuring 1 × 1.11 m or 2 × 1.4 m.

Advantages and disadvantages

The advantages of isolon include:

- high density and tensile strength. Such material does not tear well;

- the ability to form a cutting line not only with scissors, but also with a cutter. In the latter case, smoother lines are obtained;

- environmental friendliness and hypoallergenicity;

- inertness to the combustion process;

- light weight;

- the possibility of toning with pastels. Thanks to this, crafts can be given any desired shade. Allows the use of coloring compositions on a different basis;

- biological and moisture resistance;

- the possibility of reliable fixation using adhesives;

- low vapor permeability;

- elasticity;

- lack of chemical odor. The material can be used inside and outside the building;

- ease of care. Surfaces, with the exception of tinted ones, can be wiped with a damp cloth;

- long service life.

Among the shortcomings, it is worth noting:

- the disposition of the material to electrify and attract dust. This disadvantage can be neutralized by treating the surface of Izolon products with special compounds;

- impossibility plastering walls or their wallpapering without additional sheathing with rigid sheets.

Choosing an isolon for insulation

Thermal insulation materials are materials that are used to insulate various surfaces. Choosing an isolon for these purposes, one must clearly understand the conditions for its future operation. Sheets with a thickness of 5 - 30 mm are selected under the screed. If it is insulation under the laminate, 4 mm is enough.

Attention! For thermal insulation, a material with a thickness of more than 10 mm is used.

Thermal insulation material installation technology

In order for the isolon to perform the function assigned to it, the installation of the heat-insulating material must be carried out in the following sequence:

| Illustration | Description of action |

| The surface of the walls is being prepared. It is cleared of the old coating. Primed. Polystyrene plates of sufficient thickness are mounted |

| Isolon sheets of suitable thickness are cut to size and attached to the wall. To fix them, an adhesive composition or a stapler is used. Sheets are stacked end-to-end. No clearance |

| The joints are glued with an assembly tape 50 mm thick |

| The frame is mounted for fastening drywall sheets. The profile depth should be 20 - 50 mm |

| Plasterboard sheets are mounted. Finishing of the walls in progress |

You can learn about the procedure and features of additional wall insulation using izolon from the following video:

Crafts from izolona do it yourself

The quality of the surface and the characteristics of the isolon contribute to the fact that many people make interesting and very beautiful crafts with their own hands from this material. Such growth flowers can become part of any interior, allowing you to correctly place accents.

Workshop on making a lamp in the shape of an owl from an isolon

At first glance, it may seem that it is almost impossible to make a lamp in the shape of an owl from an isolon. We dare to discourage you. To do this, check out the master class that will convince you otherwise:

| Illustration | Description of action |

| We prepare sheets of Isolon with a thickness of 1 - 2 mm. We cut them into squares with a side of 2 - 3 cm. The size of the resulting elements may vary slightly. |

| We round off one side of each square and make cuts in half of the future feather |

| We take the foil and, putting the cut corrugated paper inside, we form a lump, which will be the head of the future owl. It is desirable to provide a sufficient density of the resulting element. Its diameter should correspond to the dimensions of the luminaire and be about 10 - 12 cm |

| We place the resulting lump inside the isolon sheet and carefully fix it with a thread. Cut off excess material with scissors |

| Glue the head to the torso lamp using a glue gun. We press the element as hard as possible, but so as not to crush the lamp |

| We glue the prepared isolon feathers. We do this a little overlap to form a solid canvas. We start from the bottom, gradually filling the entire surface of the luminaire. The size of the feathers should gradually decrease. The bottom should be the largest elements, on the top - the smallest |

| We decorate the face with plastic eyes. Glue the nose-shaped element |

| We form the wings. First, we cut out the base from the isolon, and then glue it with feathers from the same material |

| We check the performance of the device and the achieved effect. The torso should glow by gently diffusing light. If desired, the owl's face can be decorated in a different way, using black material |

Lamps in the form of flowers from Isolon

Original lighting fixtures immediately attract attention. Izolon flowers-lamps can be used in various rooms. We offer you to get acquainted with master classes that will allow you to figure out how to make a lamp from Izolon of various shapes and configurations with your own hands.

DIY rose lamp from isolon: master class

You can make a rose lamp from Isolon with your own hands in the following sequence:

| Illustration | Description of action |

| Isolon with a thickness of 1 - 2 mm is cut into squares with a side of 3 cm. Cut out teardrop-shaped elements from the squares. For the manufacture of 1 piece, 16 - 17 such petals are required. As a result, you get a flower with a diameter of 6 cm. |

| Cut out the leaves from the green material using a template. Draw veins with a toothpick. Using a lighter, gently heat each element and give it the required shape |

| Warming up pieces of material with a hair dryer, we make leaf prints on a special form. Cut out each leaf with scissors, carefully forming the edge of the element. Also, slightly heating the isolon, we give the desired configuration to the petals of the rose itself |

| The petals are connected in series to form a rosebud |

| The prepared elements are glued to the lamp shade. They are first evenly distributed over the surface, and then fixed with glue * |

A master class on making a rose-shaped floor lamp from isolon is presented in the following video:

Peony lamp from isolon: video instruction

Despite the fact that the queen of flowers is the rose, the peony lamp from isolon looks no less impressive. We offer you to get acquainted with the video, which describes in detail how you can make it yourself:

Workshop on making a lamp in the shape of a doll from izolon

If the lamp is intended for the children's room in which the girl lives, it is worth considering a master class on making a doll from izolon for a little princess. It includes the following steps:

- we separate the body of the doll from the legs and glue it to the plafond with a glue gun;

- we measure the distance from the waist of the doll to the surface of the table;

- cut out an equilateral rectangle from the isolon, the side of which is equal to twice the distance to the floor surface. We fold the sheet twice to get a square, the side of which is equal to the found distance;

- cut off a corner about 1 cm long to get a hole in the center of the sheet;

- round the edges of the sheet;

- we put the resulting skirt on the doll;

- heating the isolon with a hair dryer, we give the skirt the desired shape;

- we form a bodice from a cut-off rectangle;

- we decorate the dress with lace. Checking the result.

We offer you to watch a video, which tells how to make a lamp-doll from izolon in a different way:

How much is Isolon - an overview of prices per square meter

Isolon price is indicated for 1 m² and depends on the thickness of the material. For sheets with a thickness of 2 mm, the average cost is 85 rubles. For foil-clad isolon 10 mm thick, the price starts at 260 rubles. Izolon PPE L can be purchased at a lower price.

Share in the comments if you have ever used Isolon for making crafts or insulating surfaces? How satisfied are you with the result?