At the beginning of the last century, no more than two dozen types of fabric were read in the world: silk, cotton, satin, velvet, etc. Today, thanks to the development of technologies, there are many times more of them. These are natural and synthetic fabrics, in which sometimes an experienced seamstress can get confused, not to mention a beginner. In today's HouseChief review, we will consider what kind of viscose fabric it is, what its varieties exist, how this material is made, what it is used for.

Read in the article

- 1 What kind of viscose fabric: natural or not

- 2 How viscose fiber is obtained

- 2.1 Main production technology

- 2.2 Other methods of making viscose

- 3 Viscose fiber structure and properties

- 4 What is viscose fiber used for?

- 4.1 Clothes, shoes and bed linen

- 4.2 Cellophane and cellulose film

- 4.3 Cleaning equipment

- 4.4 Viscose fiber for technical needs

- 5 Advantages and disadvantages

- 6 Characteristics of viscose fabric, depending on the variety

- 6.1 Tencel and Modal

- 6.2 Acetate and cupric fabric

- 6.3 Staple cloth and siblon

- 7 How to tell if the fabric is viscose

- 8 Care advice

- 9 A few words in conclusion

What kind of viscose fabric: natural or not

The fabric got its name from the Latin word Viscosus, which means viscous, sticky. This is due to the initial raw material, which looks like a thick and viscous mass from specially prepared wood, and more specifically, cellulose. The material was invented in 1884 by the French engineer Guillier de Chardonnay, who was working on obtaining an artificial fiber with special characteristics. In the course of the experiments, the peculiarity of the fabric was revealed to change its properties depending on the method of its processing and the ability to resemble wool, silk, cotton or linen.

The British got the right to produce viscose in 1893. And almost a century later, the material gained worldwide fame and popularity thanks to the development of the textile industry and an increase in the number of enterprises producing this fabric.

Having dealt with the history of the emergence of viscose, let's consider a question that is curious for many people: is it natural or not. To answer it, you need to understand one basic principle. A person cannot make natural raw materials himself - he can only get it, for example, cotton, wool, silk, wood. Synthetic materials are completely manufactured using the latest technologies: plastic, nylon, etc. But with viscose, everything is more complicated and interesting. This is a natural material obtained by artificial means.

How viscose fiber is obtained

Since the invention and production of viscose fiber (VV), in addition to the main production technology of this material, other methods have appeared. Consider how hardwood makes an excellent fabric for making various things.

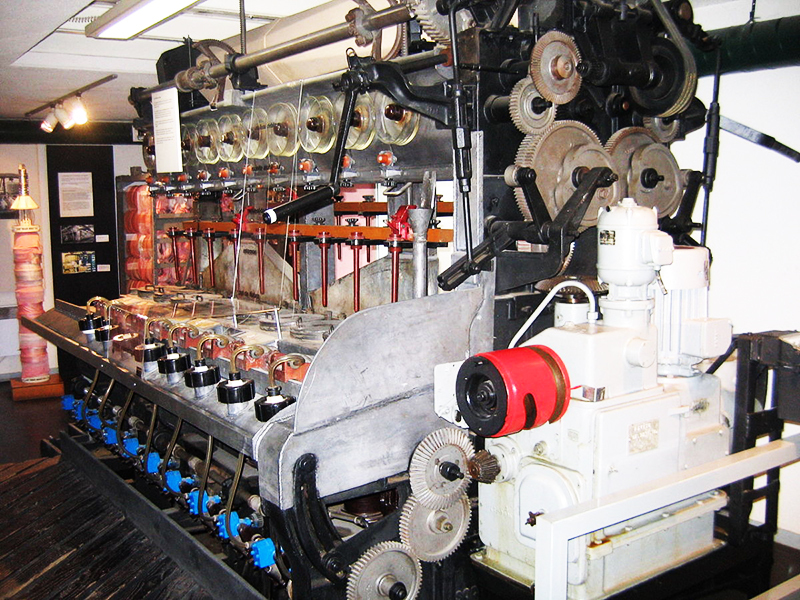

Main production technology

The production of viscose fiber is a complex process consisting of several stages. The transformation of wood into a soft durable fabric using the basic technology is as follows:

- Shredded wood is carefully digested in vats together with calcium hydrosulfite salt to obtain cellulose.

- The resulting mass is evaporated to 6-8% moisture. Then, to remove various impurities, the raw material is treated with sodium hydroxide solution at a temperature of about 45 ° C. Through this operation, alkaline cellulose is obtained.

- Further, the mass must be ripe to reduce the molecular weight of the original cellulose.

- After maturation, the raw material is treated with carbon disulfide, thereby obtaining xanthate. Next, an alkaline solution is added to the mixture, and it is thoroughly mixed. The result is viscose with 86% water content.

- For final ripening, the solution is kept for several days. At this stage, the viscosity of the raw material increases significantly.

- Viscose fiber is obtained by the wet method, passing the resulting mass into a special settling tank with acid solutions through spinnerets.

- At the final stage, a viscose thread or a short staple fabric is pulled from the prepared mass.

We have considered the traditional method of producing explosives. However, there are other technologies for obtaining this material, which are not yet used everywhere due to the complexity of the process.

Other methods of making viscose

Viscose fiber can also be obtained by dissolving cellulose in N-methyl-morpholine-N-oxide (NMMO). The production of viscose using this technology on an industrial scale was first carried out by the British company Courtaulds in 1992. 18,000 tons of viscose fiber were produced. Manufacturing using NMMO technology is carried out in several stages:

- preparation of cellulose (grinding and obtaining pulp or powder);

- introduction of methyl morpholine oxide (MMO) into the raw material;

- mixing the components in an extruder to bring the mass up to 100 ° C;

- supply of prepared raw materials to settling tanks, followed by dyeing and drying of viscose fiber.

This technology for producing explosives has its own advantages and disadvantages. In particular, the pluses include:

- Increase in wet strength.

- Compatible with almost all synthetic and natural fibers.

- Good and long-lasting coloration, obtaining a special shine.

- The production technology is environmentally friendly.

- Strength of fabric based on explosives.

- Pleasant tactile sensation from contact with fabric.

Among the disadvantages are the increased fibrillation of the fibers, the high cost of the production license and the final product.

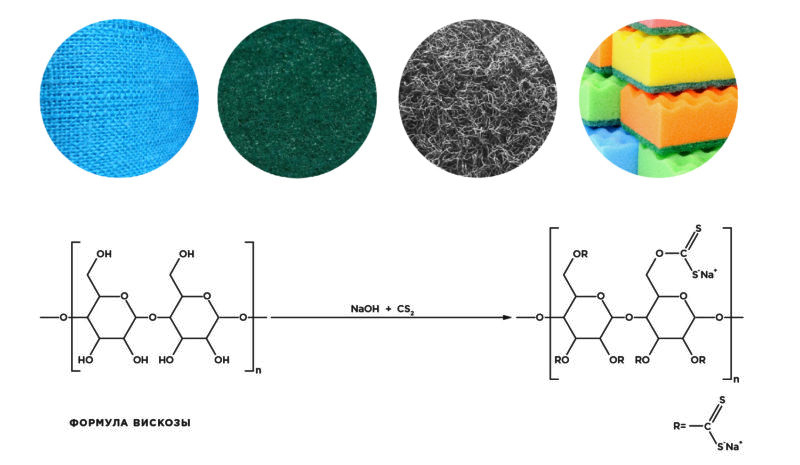

Viscose fiber structure and properties

The length and thickness of the explosive can vary depending on the intended use of the final product. In cross-section, the fiber has the shape of a ribbed circle, and the outer surface is smooth. Consider three main characteristics of viscose:

- physical: hygroscopicity, resistance to UV rays, heat resistance;

- chemical: characterized as medium;

- mechanical: abrasion resistance, medium strength (reduced by 60% when wet).

The peculiarity of the BB is that it absorbs the properties of other natural or synthetic fibers included in the fabric. Cotton gives the material softness and density, elastane - firmness and elasticity, polyester - strength and reduces wrinkle. By varying the combination of fibers with the same production technology, fabrics with different characteristics can be obtained.

What is viscose fiber used for?

Viscose yarn is used for the production of pure and blended fabrics. This fiber has a wide range of applications, from socks to conveyor belts. This became possible due to the high characteristics of the material.

Clothes, shoes and bed linen

Viscose fabric is widely used for sewing adult and children's clothing: dresses, T-shirts, underwear, shirts, blouses, skirts, socks, etc. It is also used to make lining and shoe top (slippers, sneakers, shoes, sandals). Viscose fabric is no less in demand in the production of blankets, bedspreads, bed linen, pillows, tablecloths, curtains, napkins.

Cellophane and cellulose film

In addition to fabric, cellophane and cellulose film are made from explosives, which are used in the food industry as packaging material, including for sausages. The viscose film is characterized by high moisture and vapor permeability, as well as resistance to fats and oils.

Cleaning equipment

Recently, viscose napkins have been very popular. With their help, cleaning and care of any surfaces is faster and better. Thanks to these napkins, you don't even need additional detergent when washing dishes. And due to the hygroscopicity of the material, you have to make less effort when cleaning surfaces.

Viscose fiber for technical needs

Modern industry produces fairly strong viscose fiber for technical needs. In particular, viscose thread is used for the production of:

- cord thread for car tires and conveyor belts;

- tarpaulin cloth, fire hoses and seat belts;

- automotive upholstery and canvas;

- sealing means for equipment operating in an aggressive environment;

- ropes, twine and consumer goods.

The main advantage of explosives is that it is completely non-toxic, does not have a negative effect on the human body through direct contact.

Advantages and disadvantages

Viscose has a lot of advantages, which is confirmed by the great popularity and wide applications of the material made from this fiber. The indisputable advantages of viscose fabric include the following:

- Softness, pleasant tactile sensations in direct contact with the body.

- Aesthetics.

- Resistant to UV rays.

- Easy staining.

- Low weight. The material is about 2 times lighter than silk.

- Good thermoregulation.

- Hygroscopicity.

- The ability to pass air (breathe).

- Antistatic and hypoallergenic.

- Environmental safety.

However, despite the large number of advantages, viscose also has a number of disadvantages, namely:

- special care is required for the material;

- increased creasing;

- poor tolerance to high temperatures;

- shrinkage of the material is possible;

- deformation and loss of strength when wet.

For your information! To eliminate the existing disadvantages of viscose fiber, special protective synthetic impregnations are used.

Characteristics of viscose fabric, depending on the variety

Pure rayon fabric is 100% cellulose. The material is delicate and soft to the touch, has a shiny surface, low strength and elasticity. Pure viscose is mainly used for the production of fine, lightweight clothing. There are several types of rayon fabric. Let's briefly consider their features.

Tencel and Modal

Tencel (commercial name for lyocell) is made from 100% Australian eucalyptus cellulose. The fabric is soft to the touch, reminiscent of silk, has good strength characteristics, air and moisture permeability. Improper care will cause the material to wrinkle. This type of viscose is used to make home textiles, bedding and underwear. A pure tencel is expensive, so bamboo, wool or cotton fiber is added to it to reduce the cost of production and increase strength.

Modal is a 100% viscose fabric of natural cotton fiber quality. The material is durable, durable and highly hygroscopic. The fabric is mainly used in the production of high-quality casual and sportswear, bedding and underwear. The material is capricious in washing, does not tolerate high temperatures.

Acetate and cupric fabric

Acetate is an inexpensive fabric as it is made from cellulose waste. The material is thin, lightweight, resistant to deformation and creasing. It is poorly permeable to air, does not tolerate exposure to chemicals and poorly absorbs moisture. Most often, acetate is used as a lining fabric when sewing clothes.

Premium-class cupric fabric made of cellulose and cotton "down", has an external resemblance to silk, differs high quality, durability, thermoregulation, elasticity, good air permeability, but capricious in leaving. The manufacturing process for cupra is rather complicated and expensive. The material is used for the production of evening and holiday dresses, as well as bedding.

Staple cloth and siblon

The staple is made from short fibers of the same length, due to which the fabric acquires elasticity. The material has a different structure. It is soft, durable, good to wear, less wrinkled. The fabric is made from viscose with the addition of cotton fiber. Differs in softness, environmental safety. The fabric is mainly used for sewing summer clothing for adults.

Siblon is a kind of viscose fabric made from cellulose obtained from coniferous wood. To the touch, the material resembles silk and has almost all the positive characteristics of explosives, but enhanced by 1.5-2 times. The fabric is characterized by hygroscopicity, good air permeability, resistance to shrinkage and deformation. Perfect for sewing festive outfits.

How to tell if the fabric is viscose

The modern textile industry offers a wide range of different fabrics: natural and synthetic. Sometimes even an experienced seamstress finds it difficult to determine exactly what fibers a particular material is made of. To find out that viscose is in front of you, use the simple methods:

- Visual definition. The viscose fabric is quite strong, dense, with a smooth shiny or matte surface. The fabric is as cool as silk to the touch.

- Crumple test. The fabric must be firmly squeezed in the hand for about 30 seconds, then release and smooth with the palm of your hand. Next, it is necessary to assess the degree of tissue deformation and the resulting folds.

- Trial by fire. It is necessary to take a small piece of cloth, set fire to its edge and observe the flame. Since viscose is composed of wood pulp, the flame will be stable and the smell of burnt paper will appear. The charred fibers of rayon fabric should crumble at the slightest touch. The material burns out rather quickly both in an open flame and when removed from it.

Care advice

Viscose fabric is a very good material, but it requires careful handling and maintenance. Otherwise, shrinkage, pilling, deformation, loss of brightness and gloss are possible. To prevent this from happening, manufacturers recommend following a few simple guidelines:

- only hand wash is desirable;

- the fabric should not be strongly rubbed and wrinkled;

- do not use aggressive chemicals for washing;

- if you cannot do without a washing machine, then use the DELICATE mode;

- it is not recommended to wash in water with a temperature higher than 30 ° C;

- use a terry towel to wring out the viscose fabric. The product must be carefully laid out on it and rolled up. So the towel will absorb excess moisture, and the fabric will not be deformed;

- it is necessary to dry viscose clothes on a horizontal surface;

- ironing is performed with an iron set at the minimum temperature without steaming or spraying.

A few words in conclusion

Viscose fabric is a wonderful material. He has a lot of advantages. It is suitable for sewing beautiful quality bedding and underwear, casual and party wear, as well as home textiles. Now, knowing everything about viscose, it will be easier for you to make a choice of one or another textile product. We hope our article was useful to you, and you will appreciate it in the comment form.