New construction technologies have become part of our everyday life, and now build a bath, garage or even House can be quite inexpensive using wireframe technology. The only question remains with the decoration - after all, the appearance of the building has both an aesthetic side and a practical one. There is not enough beautiful appearance, because it is necessary that the finish lasts a long time and reliably protects the structure from unfavorable external factors. And since we are talking about savings, then the cost of materials and the ability to mount them without outside help are also important. If you put all these requirements together, then it would be logical to pay attention to the wooden paneling, which is excellent for solving such a task.

Read in the article

- 1 Some theory: what and how to fix

- 2 Which breed is best suited for exterior cladding

- 3 How to make a cladding from a regular board that imitates a bar

Some theory: what and how to fix

The timber cladding is attached to the frame. It is undesirable to use for this purpose nail gun. There is no dispute, this tool greatly reduces the time and makes the work easier, but there is a great danger that the boards will split when sheathing. It will be much more careful to work with a hammer and ordinary stainless steel nails, and even better - self-tapping screws and screwdriver.

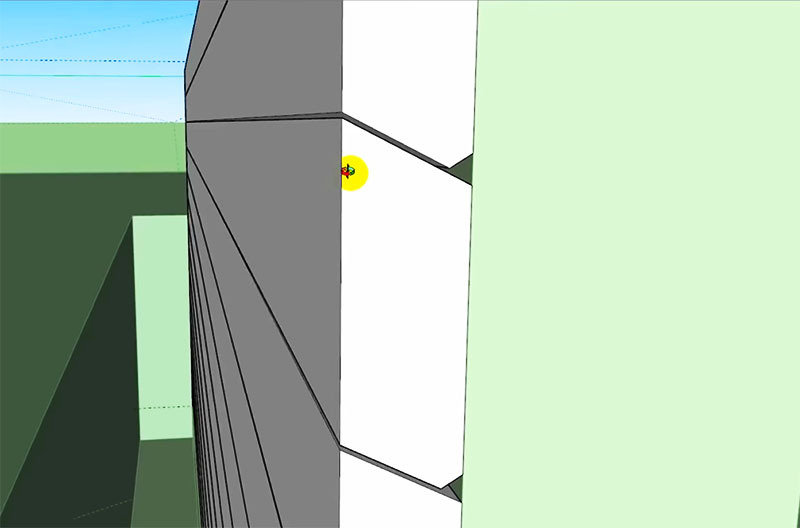

The options for the location of the boards can be the same as in the photo examples. As you can see, options 7 and 3 are the easiest to make. Moreover, 7 is a solid sheathing, and 3 is a semi-crisp, which looks like a bar from the outside.

The rest of the cladding options involve the manufacture of a tongue-and-groove system in different configurations, and this requires a special tool.

Which breed is best suited for exterior cladding

So what is the best wood to choose for the exterior cladding of a frame structure? The best option would be larch, which is not afraid of water, is easily processed and is not subject to strong deformation when wet and dried.

Spruce will be cheaper, but such wood usually has a lot of knots, which then turn into cracks.

Hard breeds look gorgeous, for example - cedar. But such wood is difficult to handle, and besides, it often gives cracks from nails. And at the cost of such a cladding can not be called economical.

How to make a cladding from a regular board that imitates a bar

For cladding, an edged board with a thickness of 4-5 cm is useful for you. It looks a little expensive at first glance, but such boards will last for more than a dozen years, so literally build and forget.

In this way, you can execute and internal, and the outer cladding. The main advantage of the method is the simplicity of manufacture and the fact that installation does not require special skills and tools. And here is another option for wood sheathing, which can also be attributed to the budget:

What kind of wood cladding do you like? Share your experience and impressions in the comments!