If you cannot purchase a single roll on the floor of the room, you will have to form a decorative coating from separate fragments. In this case, the question arises of how to solder linoleum at home. There are various methods that you should definitely be familiar with in advance.

Read in the article

- 1 The main methods of soldering linoleum

- 2 DIY cold welding of linoleum

- 2.1 Choosing glue

- 2.2 Canvases joining technology

- 3 Self-welding of linoleum with a hot method

- 3.1 Tools and materials

- 3.2 Sequencing

- 4 How to solder linoleum at home: a sequence of actions

- 4.1 What you need to work: the necessary tool

- 4.2 How to solder linoleum: procedure

- 5 Which soldering method is best for different flooring classes?

- 5.1 Commercial and semi-commercial linoleum

- 5.2 Household linoleum

The main methods of soldering linoleum

To form quality connection can be used:

- Double sided tape, with which you can fix the strips of linoleum without applying significant effort. This method is rarely used because of its impracticality.

- Porozhek. Installed at the entrance to the premises. They come in different sizes and shapes. They not only fix the mating layers, but also perform a decorative function.

- Hot welding, ensuring the connection of individual fragments with preheating to a sufficiently high temperature. A strong connection of the strips is ensured through the use of filler material.

- Cold welding. A universal option suitable for joining all types of linoleum. The joint can be welded using a special compound. It is distinguished by the simplicity of installation work, due to which it attracts attention when performing work on its own.

DIY cold welding of linoleum

Due to its ease of implementation, cold welding has become quite widespread. This method is actively used when doing work at home. You just need to find a suitable composition.

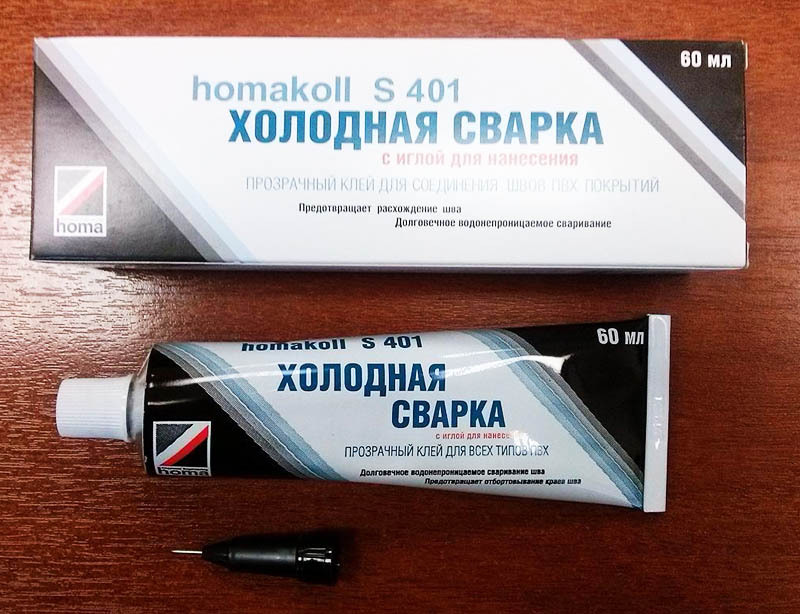

Choosing glue

Adhesives for cold welding are offered by many manufacturers.

Cold welding products include:

- Solvent to melt PVC. However, it will be useless when processing other types of coatings.

- Filler. This is usually liquid PVC.

In addition, the existing varieties are usually divided into three types, depending on the consistency. When choosing, you should take into account the width of the gap between the canvases.

Depending on this, the glue can be of the type:

- BUTcontaining a large percentage of solvent. It is used when the width between linoleum sheets does not exceed 1 mm. Due to its liquid consistency, it easily penetrates the gap, ensuring sheet joining without overlap.

- WITH, has a thicker consistency. Can be used if the gap is 2-4 mm. Less solvent allows high-quality joint filling, even with uneven material edges. Allows you to restore the old coating without removing it from the floor.

- T. Such an adhesive composition is almost never used in everyday life. Relevant when it is necessary to glue multi-component coatings. It is based not only on PVC, but also on polyester. Creates a strong elastic seam.

When choosing a specific composition, you should pay attention to products released under popular trademarks:

- WernerMuller;

- Tarkett;

- Rico;

- "Second";

- Sintex;

- Tytan;

- Axton.

Advice! Before buying, it is worth calculating the required amount of adhesive. It depends on the qualifications of the person who will do the job, the type of glue and the thickness of the linoleum.

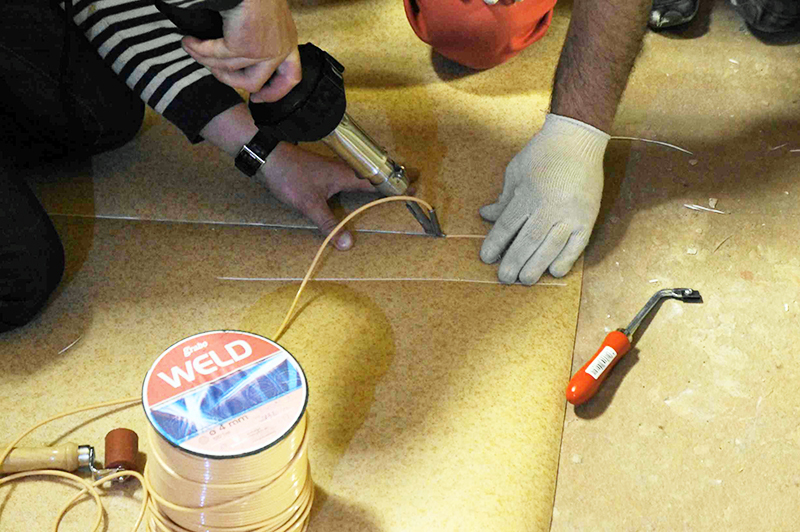

Canvases joining technology

The connection of linoleum canvases is performed in the sequence shown in the table.

| Illustration | Procedure |

| Both connected canvases fixed on the base with double-sided tape. To do this, raise each half, stick a strip of tape and press the canvas. |

| Both strips are connected to each other using masking tape. Provides a snug fit to the strips, avoiding overlap. The masking tape is carefully cut along the seam. |

| The adhesive is applied to the junction. To form a high-quality seam, a special nozzle is used, which allows cold welding to penetrate under the coating. The adhesive should protrude above the masking tape. |

| The excess amount is removed from the surface. At the same time, deeper penetration of the composition under the linoleum is additionally ensured. |

| After 60 minutes, the masking tape is removed from the surface, and the formed seam has sufficient durability. |

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

"In the absence of a special nozzle, a clerical knife can be used to penetrate the adhesive under the coating."

Watch the following video to understand in detail the technology for performing work:

Self-welding of linoleum with a hot method

The method is suitable for commercial grade linoleums. It is used for joining material in large rooms. At home, it finds limited use due to the need to use a specialized tool that will allow you to solder two fragments together.

Tools and materials

To make the connection, you must have a building hair dryer for soldering linoleum. Buying it is a rather expensive undertaking, and therefore, if it is not possible to rent a hairdryer, they prefer alternative options.

A filler cord made of PVC is required to form the joint. Passing through the nozzle, it melts, ensuring the formation of a strong and high-quality connection.

Sequencing

If it is decided to use the hot method, the work is performed in the following sequence:

- Linoleum is spread on the floor and fixed with glue, after allowing it to soak.

- Using a cutter, a groove is formed, the dimensions of which depend on the transverse dimensions of the cord intended to form the seam.

- A nozzle is installed on the hairdryer, through which the cord is threaded.

- The hair dryer is heated to an operating temperature of the order of + 250-350 ° C.

- The cord is warmed up with its subsequent laying in a groove. The filler material should be laid as tightly as possible.

- After the joint has cooled down, the excess material is cut off. Existing irregularities are removed using a grinding wheel or other abrasive tool.

How to solder linoleum at home: a sequence of actions

As a rule, not everyone has a hair dryer. In this case, a soldering iron or iron can be used as a heat source. You can do the work yourself if you know how to solder.

What you need to work: the necessary tool

To create a high-quality floor covering at home, you need to have in stock:

- rule;

- sample;

- metal ruler;

- construction knife;

- a soldering iron with a power exceeding 1 kW;

- roller made of metal or plastic.

How to solder linoleum: procedure

The method allows you to form a tight connection, ensuring the fit of the edges butt. If it is necessary to form a pattern, the laying is carried out with an overlap. This is done when creating a unique interior in an apartment. After that, both layers are cut according to the pattern. The cutting tool must be sharp to keep the flanks smooth.

Then they act as follows:

- Bend the tip of the soldering iron at an angle that best suits the job.

- The soldering iron is warmed up. The required heat level can be checked on the remnants of the material or on a place that will later remain invisible. The material should melt after contact with the soldering iron.

- They begin to melt the decorative coating at the joints, preventing deep deformation of the material or a change in its color.

- The junction is rolled with a roller.

Attention! When soldering, the tip should be vertical, and the soldering iron should be moved towards you.

Which soldering method is best for different flooring classes?

Linoleum of various types is presented in the catalogs of manufacturers. The material differs in operational and technical characteristics.

Taking this into account, linoleum is usually divided into:

- Household, has a pleasant appearance.

- Commercial, presented in a limited range.

- Semi-commercial.

When choosing a connection method, take into account the type of coverage, financial capabilities and the available tool.

Commercial and semi-commercial linoleum

Cold welding is used for all types of decorative coatings, so it can also be used for joining commercial and semi-commercial linoleum. Hot method is suitable for commercial grade material.

Household linoleum

This type is connected using a soldering iron or by cold welding. The first method is relevant if the length of the connection is relatively short. It is quite difficult to form a high-quality, long-length joint using a soldering iron.

Share in the comments which method you had to use and how satisfied you were with the result.