Solid fuel boilers can operate on wood and coal, fuel granules (pellets) and briquettes from sawdust and peat.

CONTENT

- 1 Advantages and disadvantages of long-burning boilers

- 2 Types of solid fuel boilers for long burning for heating

- 3 Device, principle of operation and technical characteristics

- 4 Leading manufacturers of similar equipment

- 5 How to calculate the power of a heating boiler

- 6 How to choose a wood-burning boiler for long burning - recommendations of our editorial staff

- 7 Installation and operation rules

- 8 Homemade boilers for long burning on wood - the nuances of manufacturing

- 9 How much does a long-burning boiler cost - price overview

- 10 FAQ

- 11 Video: DIY long-burning solid fuel boiler

Advantages and disadvantages of long-burning boilers

Among the heating equipment designed to obtain thermal energy used for heating and hot water supply of household and industrial facilities, in a special place are long-burning boilers operating on solid fuel. Such attention to such equipment is associated with the presence of a sufficient number of advantages, in comparison with analogues, when using them, which can be formulated as follows:

- high efficiency of use;

- environmental Safety;

- relatively low cost of the fuel used;

- versatility (heating and hot water supply);

- long service life;

- ease of maintenance.

Along with this, of course, there are disadvantages, but they are incomparably fewer:

- the need for certain reserves of used fuel;

- labor intensity of maintenance, expressed in periodic cleaning of chimneys and boiler chambers;

- strict requirements are imposed on the installation site, regulated by fire safety rules and building codes.

Types of solid fuel boilers for long burning for heating

Long burning solid fuel heating boilers used for heating a house are of two types:

- Mine or upper combustion boiler. In such devices, fuel is burned in its upper layers, and the entire boiler body is the heat exchanger.

Air is fed into the stacked firewood (coal) through a special telescopic tube from top to bottom, after which, moving in the opposite direction, it contributes to the combustion process.

Top combustion boilers (mine) are universal in terms of the types of solid fuel used (coal, firewood and recycled waste from woodworking industries) - Pyrolysis boilers (gas generators). Combustion in such units occurs from top to bottom, and the process itself is carried out with limited access oxygen, resulting in the formation of ash and pyrolysis gas, which, in turn, is burned in the furnace camera.

Device, principle of operation and technical characteristics

Different types of long-burning boilers differ in their design, principle of operation, and also have their inherent advantages and disadvantages, as a result of which they should be considered separately from each other friend.

Long burning mine boiler

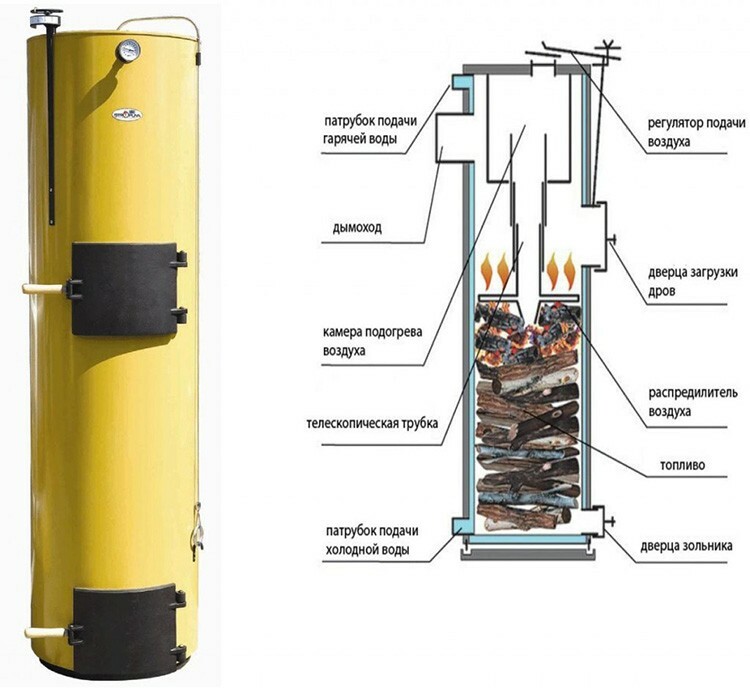

The design of the upper combustion boiler is shown in the following figure, where it can be seen that the main elements of such units are:

- the body on which the operation control elements are mounted (air supply regulator, doors for loading fuel and ash pan, chimney);

- air heating and fuel combustion chambers;

- supply tube and air distributor;

- branch pipes for connection to the heating system.

A mine boiler can be designed as an independent heat source or be part of a heating system, as shown in the above figure. In this case, a boiler of this design is called a single-circuit with a water circuit. The operation of a heating boiler of this type is carried out as follows:

- after the fuel is loaded and ignited, the air supply regulator is open, it ensures its flow into the upper layer of the stored fuel through the movable distributor;

- as the fuel burns out, the distributor goes down, thereby supplying air to its lower layers;

- the fuel burns evenly layer by layer, while releasing combustible wood gas;

- the gas enters the second chamber (afterburner), where it ignites and, burning, releases a large amount of thermal energy;

- a water circuit is mounted in the boiler body, through which the heating agent of the heating system circulates, therefore the entire area of the boiler is its heat exchange element.

The main technical characteristics of such equipment are:

- power, measured in kilowatts (kW);

- heated area (m2);

- the amount of fuel available for placement in the combustion chamber (m3 and kg);

- the size of firewood that can be used, (cm) - for boilers running on wood;

- the amount of water in the boiler jacket;

- burning time of one bookmark;

- Efficiency;

- the maximum possible pressure in the heating system;

- geometric dimensions of the boiler as a whole and its individual elements;

- weight.

Long burning pyrolysis boiler with a water circuit

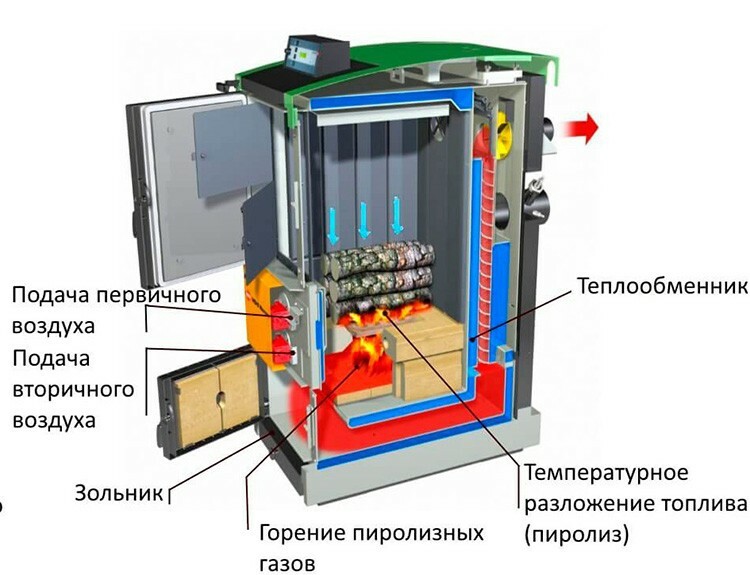

The design of the pyrolysis boiler assumes air supply from above to the stored fuel (firewood), which is provided by its primary supply system. The laid firewood begins to smolder after firing up, which is achieved by the design of the boiler, which provides a limited air supply at this stage of operation.

The wood gas released during this process (pyrolysis effect) enters the second chamber, where it is mixed with secondary air and burned. Due to the fact that the fuel pyrolysis process takes a long time, then the operation of the boiler on one tab is also quite long. The pyrolysis gas, burning, gives up its heat to the heat carrier circulating in the heat exchanger of the solid fuel boiler, equipped with a water circuit and connected to the heating system. The main technical characteristics of pyrolysis boilers are:

- the type of fuel used;

- material used in the manufacture;

- burning time on one tab (hours);

- power, kWt);

- heated area (m2);

- number of contours;

- Efficiency;

- fuel consumption (kg / h);

- dimensions of the boiler, furnace and other structural elements;

- weight (kg).

Varieties of boilers for long burning

In addition to the fact that long-burning boilers differ in their design (type), they can still have differences in such parameters as the presence of an automation system and a different number of water contours. The presence of two circuits in the design of the boiler allows it to be used not only for heating, but also as a source of hot water supply. In such models, one internal circuit of the unit is connected to the heating system, and the second to the hot water supply system. An automatic solid fuel boiler is a complex of technical means that ensure the operation of a heating device without human participation in this process. The greatest degree of automation is observed in boilers that use pellets (fuel granules) made from woodworking waste (sawdust, wood chips, etc.) as fuel.

Leading manufacturers of similar equipment

Products of Russian and foreign companies engaged in the production of solid fuel heating boilers are presented on the domestic market.

The most popular in this segment of equipment are models of companies such as:

- Buderus, Czech Republic;

- Candle and STROPUVA, Lithuania;

- "Plant TeploGarant", Russia (g. Kostroma);

- Viessmann, Germany.

How to calculate the power of a heating boiler

The power of the boiler determines its performance and at the same time affects the cost of the heating unit, the higher the power, the more expensive the heating boiler. In this regard, in order to avoid unnecessary financial expenses, when choosing a long-burning boiler, you need to calculate the required power of such a device, which can be done in two ways:

- Considering the average power density per unit of heated area. In this case, the value of 1 kW per 10 m2 is taken as a basis, with a ceiling height of up to three meters. Dividing the value of the available area of the premises to be heated by 10, we obtain the approximate output of the heating boiler.

№ 18. A long-burning wood-burning boiler will ensure the autonomy of the heating system of a country house - Using the volume of the heated room and the degree of its thermal insulation. In this case, the calculation is performed according to the formula:

P = S × h × k, where

P - heating boiler power (kW);

S - area of the heated room (m2);

h - height of the heated room (m);

k - the coefficient taking into account the degree of thermal insulation is 40 - for well-insulated rooms and 60 - with poor thermal insulation and a large glazing area of building structures.

For more accurate calculations, we suggest using a convenient online calculator.

How to choose a wood-burning boiler for long burning - recommendations of our editorial staff

It is sometimes difficult for an untrained user to choose one or another technical equipment, because the variety of proposals does not allow you to concentrate on the main selection criteria - which ultimately leads to unnecessary financial spending or the inability of the purchased device to cope with the set tasks.

Experts of our editorial office recommend paying attention to the following points when choosing a model of a wood-burning boiler:

- initially, the required power of the heater and its scope of use (heating, heating + hot water supply) should be determined;

- it should be remembered that in the manufacture of such equipment, steel or cast iron is used, and each of the materials used has its own advantages and disadvantages;

- reliability is guaranteed by the manufacturer, so you need to find user reviews about the model you like, as well as about the company as a whole.

Installation and operation rules

In order for the operation of heating equipment to be long-term and trouble-free, it is necessary to initially perform its correct installation, and then use it correctly.

When installing boilers for long burning, it is necessary:

- Protect building structures from high temperatures and the possible ingress of burning parts of fuel on their surface.

- The chimney should have the least number of bends, its height above the surface of the roof, should correspond to its shape.

- The boiler and chimney connections must be collapsible.

The rules for installation and operation are described in the accompanying documents for a specific model, however, when using such equipment, remember that:

- firewood must be laid loosely in the firebox to ensure air circulation;

- the amount of incoming air (draft) can be adjusted using a gate and an ash pan;

- maintenance of long-burning solid fuel boilers consists in removing ash and cleaning the grates, as well as cleaning the chimney.

Homemade boilers for long burning on wood - the nuances of manufacturing

If you have free time, the ability to work with a hand tool, and also having a desire, a long-burning boiler on wood can be made independently. When making with your own hands, you must remember that:

- The larger the chamber intended for loading fuel, the longer the process of burning it will take.

- The ash chamber must be hermetically closed, because air enters the working area of the boiler from top to bottom.

- In the upper chamber, it is necessary to provide a damper designed to regulate the air supply.

- To ensure long-term operation of the unit under construction, the metal thickness must be at least 5 mm.

How much does a long-burning boiler cost - price overview

The following table shows the average cost for long-burning boilers discussed in this article, as of Q2 2018.

| Model | Cost, rubles |

| "STROPUVA S 40" | 120 000 |

| "Candle S-18kW" | 88 000 |

| "BuderusLogano G221-40" | 105 000 |

| Geyser PK-10 | 45 000 |

| "ViessmannVitoligno 100 VL1A025 30 kW" | 245 000 |

| "Bourgeois K TA 20" | 65 000 |

| "BuderusLogano S111 20" | 75 000 |

| "Stropuva S10" | 90 000 |

| "ViadrusHercules U22D-4" | 55 000 |

You can buy an inexpensive long-burning wood-fired boiler from the company that produces it, as well as its dealers, on the network The Internet, where a large number of proposals from organizations involved in the implementation of such equipment.

FAQ

Why does the pressure drop in an electric heating boiler?

There may be several reasons for this. First of all, the pressure in the system drops at the first start-up, when from pipes filled with coolant air comes out - this is a completely normal phenomenon, for this there are even special air vents. This process can take quite a long time, up to two weeks in a floor heating system. In addition, it is possible that the expansion tank, whose task is precisely to contain pressure drops, is almost filled with coolant. If there is no room for air in the tank, then the excess pressure in the system will be relieved through the safety valve. Finally, the most unpleasant and most commonplace reason is a leak in the heating system. In this case, the leak must be identified and repaired so that the pressure stops falling.

Video: DIY long-burning solid fuel boiler

Read also:

The best gas boilers Baxi