Submersible pumps must have a good length of the electrical cord so that there is enough margin for the voltage source.

CONTENT

- 1 The internal structure of a submersible pump and its principle of operation

- 2 Distinctive properties of submersible pumps, depending on the type

- 3 Leading manufacturers of submersible borehole pumps

- 4 The best models of submersible pumps, according to the editors of Tehno.guru

- 5 Features of choosing a unit for a well

- 6 What is important to know when choosing a submersible pump: key points

The internal structure of a submersible pump and its principle of operation

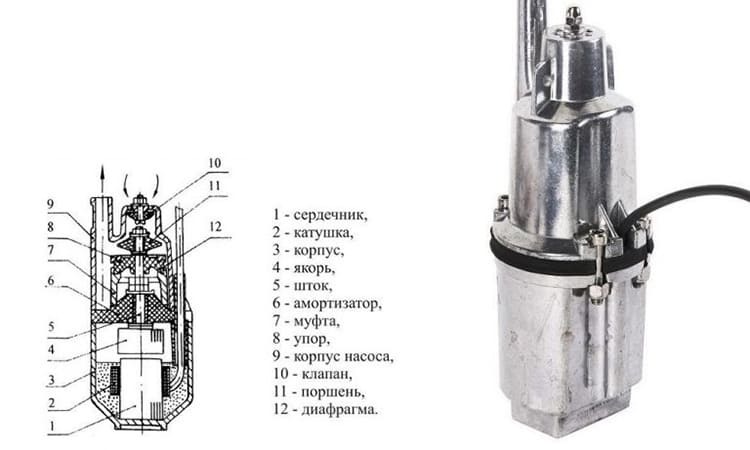

The type of construction of a submersible pump may vary depending on its operating principle. For example, a pumping mechanism and a built-in motor are mandatory components of a vibration device. The latter is located at the very bottom of the unit and is protected from water. Also, the device has a vibrator, through which pressure is created to pump water through the riser pipeline.

The vibrator itself includes an armature, adjusting washers and a rubberized shock absorber. Such a mechanism gives the equipment a more stable operation without failures and violation of the sealing of the walls.

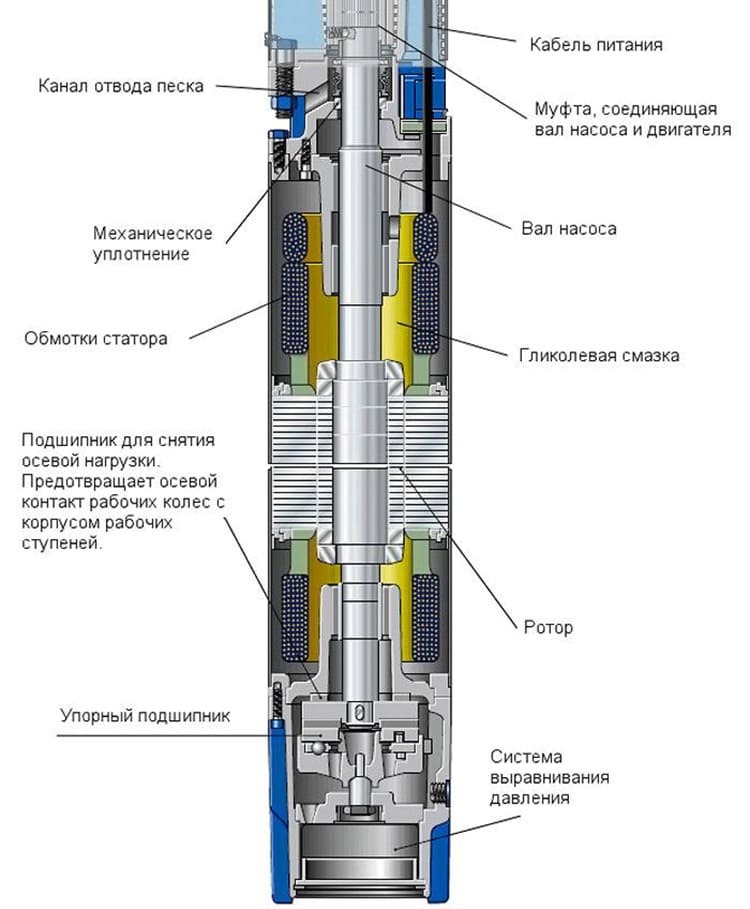

With regard to deep centrifugal units, their design has some differences. A huge role is given to the blade type of the engine. These pumps have their own cooling system. Due to the fact that the liquid passes through the internal mechanisms, the bearings operating during start-up do not have time to overheat. Therefore, such devices are considered to be the most durable. Such pumping equipment has special protective devices. All parts of the movement are packed in a reliable metal case.

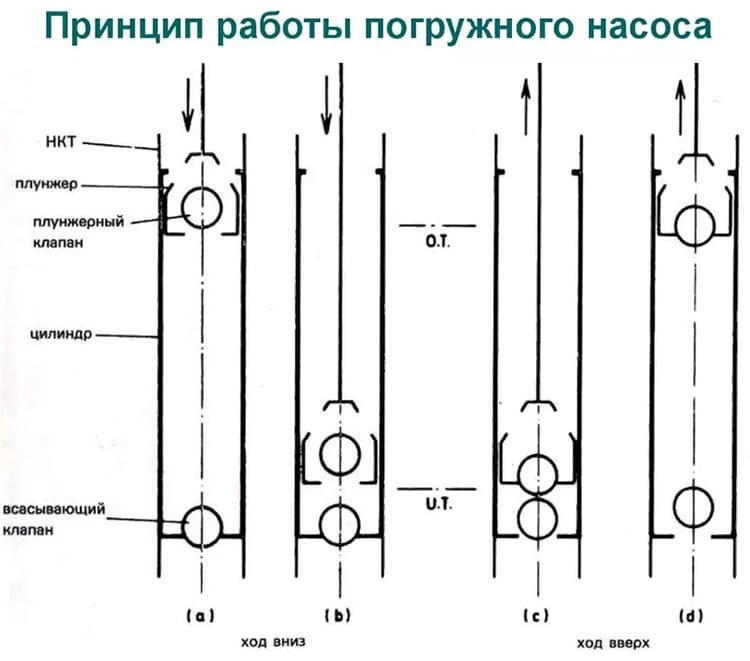

The principle of operation of submersible pumps also has some differences. In a vibration pump, the entire process of pumping water takes place by means of a special movable piston. When launched, an electromagnetic field is formed inside the device, which causes a vibrator to move, which sets the piston in motion.

The centrifugal pump works by means of a special wheel that creates centrifugal force, which pushes water into the pressure channel from the water intake pipe. A similar principle of operation for a well screw pump.

Distinctive properties of submersible pumps, depending on the type

A submersible pump is a device that can be partially or completely submerged in water. Such designs also differ in other features. We propose to study the capabilities of each type of pump.

Centrifugal structures

There are normally suction and self-priming pumps with a working shaft. The first version of the units begins to function when the inlet pipe is completely filled with water. The second type of pump is characterized by the presence of air in the tube in order to start the operating mode.

Vortex pumping stations

The purpose of using vortex pumps is to pump water from a well. However, such designs are also suitable for transporting gaseous substances. This type of equipment can be operated with a low water level in the well. With all this, this situation will not affect the quality of the pressure.

Screw aggregates as an alternative to surface

Submersible screw pumps are submerged for the entire duration of use. The main component of the mechanism of this type of pump is the "Archimedes screw". Water is pumped into the piping system using a wide bladed impeller. However, such models are too sensitive to the ingress of small particles of earth rocks: stones, sand, limestone.

Well vibrating units

Vibration-type structures have a special mechanism in which there are no any kind of moving parts. This suggests that such pumps are able to last much longer than analogs with rotating engine parts. Most often, such units are used as a protector for autonomous cooling systems.

Leading manufacturers of submersible borehole pumps

Both domestic and imported submersible pumping devices deserve the same praise. Consider popular foreign designs.

- Grundfos. A well-known brand specializing in the production of pumping equipment in Denmark. The concern manufactures submersible and surface models. The main feature of the products is their use in the production of stainless steel.

- Marina. Pumps of this brand have a centrifugal internal design with a single impeller. Such devices are used to fill volumetric reservoirs with water from wells and deep wells.

- Speroni. These units are considered to be quite expensive. They are designed to pump only perfectly clean water that is suitable for drinking. This is due to the fact that a mesh filter is installed inside, which is able to protect the internal mechanism only from rocks of a coarse fraction (up to 3 mm).

- Amarex. Units with normal suction and one working monoblock. Such units can be single and multi-channel. The devices of the declared trade mark are equipped with explosion protection and have an asynchronous three-phase motor.

As a rule, products of foreign manufacturers are distinguished by high rates of practicality. Of course, equipment with multiple degrees of protection will cost many times more than classic modifications of devices.

Among Russian brands producing deep well pumps, it is worth highlighting:

- Irtysh (the density indicator of liquids should be no more than 1100 kg / m³);

- "Baby" (designs vary greatly in quality depending on the cities in which the manufacturer's branches are located. Only those products made in Livny enjoy positive reviews);

- "Gilex" - models resembling Chinese pumping units. There are several options. They differ in power and method of operation.

Nevertheless, each of the offered brands provides its consumers with a wide range. From the listed manufacturers, you can choose the right unit for your individual application.

ON A NOTE!

To use submersible pumps, it should be borne in mind that the static water level in the well must correspond to the characteristics of the equipment (see the package or check with the consultant).

The best models of submersible pumps, according to the editors of Tehno.guru

As it turned out earlier, with the help of deep pumps it is possible to pump water from the deepest sources without loss of pressure. However, not all users are well versed in this type of technique. Our editors are ready to provide information on the existing most optimal models with excellent performance qualities and not only.

Pump Grundfos SQ 2-85

A submersible borehole pump that develops high power and is able to create maximum head force. Such a unit can be installed horizontally and vertically. The design of the pump is designed to transport liquid exclusively in its pure form without the presence of impurities and metals.

| Power, W | Productivity, m³ / hour | Device weight, kg | Head, m | Water temperature tolerance, ºС |

| 1650 | 3 | 6,2 | 109 | 35 |

Pump JILEKS Poplar 3D 70/60

The pump is designed for pumping drinking water. Used for artesian sources. Such units are not recommended for operation in wells-top, intended for watering the garden and vegetable garden.

| Power, W | Productivity, m³ / hour | Immersion depth, m | Head, m | Filter, mm |

| 900 | 4,2 | 80 | 60 | 1,5 |

PATRIOT SP 3250S pump

This pump may only be operated vertically. The claimed analogue is also intended for use only in conditions of perfectly clean wells.

| Power, W | Productivity, m³ / hour | Weight, kg | Immersion depth | Security options |

| 750 | 1,92 | 11,2 | 80 | Dry running |

Pump BELAMOS TF3-40

A model with good performance and low noise. The device copes with the transportation of perfectly clean water. The unit is installed in a strictly vertical position and has built-in overheating protection.

| Power, W | Productivity, m³ / hour | Head, m | Immersion depth, m | Weight, kg |

| 550 | 2,7 | 42 | 80 | 9,4 |

Pump CALIBER NPCS 1,2 / 50

Standard submersible device with stainless steel body. The unit is designed for shallow wells, as it has rather weak characteristics and, accordingly, the minimum immersion depth.

| Power, W | Productivity, m³ / hour | Head, m | Immersion depth, m | Pump type |

| 370 | 1,2 | 50 | 5 | Centrifugal |

Features of choosing a unit for a well

Having understood the existing models, it is necessary to take into account the general requirements that the subsea structure must meet. First of all, the unit must not have external defects and meet its performance characteristics. The following important points are worth noting:

- The integrity of the enclosure is an important feature that must be respected without fail. If there are any chips, scratches or cracks on it, this unit is clearly defective or has already been used. Such defects are unacceptable. They will quickly disable the apparatus. In addition, there is a risk of short circuits.

- Ask the price for models that have several degrees of protection. A prerequisite is the presence of protection against dry running. This is typical for upstream wells, however, the separation of the water mirror is permissible in artesian springs as well.

- The equipment must be clean. Discard units on which rust has already appeared. This suggests that this unit was stored in damp conditions.

- Make sure that the brand, model and technical characteristics of the device correspond to those shown on the packaging. Typically, such data is duplicated by stickers on the pump body itself.

These are the basic requirements that will allow you not to make a mistake in the choice of equipment.

What is important to know when choosing a submersible pump: key points

The choice of subsea pumping equipment strictly depends on the characteristics of the well. If it was drilled by professionals, then the owner will always have a technical passport of the source, which contains all the necessary data. They should be guided by when buying a deep pump.

ON A NOTE!

In case the well was created with your own hands, you will have to independently look for an opportunity to measure all the parameters.

Performance quality

Produced capacity (productivity) should be calculated based on the number of family members and rates for additional costs. For example, if one person lives in a house, then 200 liters of resource per day are enough for him, respectively the performance of the unit should not be less than 1.9 m³, for example, for watering a vegetable garden of these characteristics more than enough. As an introduction, it is worth adding the per-minute water consumption at the water intake points of the house:

- Bathroom, shower - 10 l / min;

- Toilet - 6 l / min;

- Sink - 6 l / min.

For an average family of three to four people for domestic water use, the pump performance should be within 2-3 m³ / hour.

Head height

As a rule, water from the well to the water intake points should be transported without interruptions and air locks. Therefore, it is so important to take care of the head of the unit. To calculate this indicator, you need to use the following formula: H = Hgeo + (0.2 · L) + 10 [m], where

- H is the head for a given water intake source, as well as the indicator of the vibration pump;

- Нgeo - the height of the branch pipe from the place where the pump is immersed to the highest point of the water intake;

- 0.2 - coefficient of resistance along the length of the casing;

- L is the length of the pipeline (horizontal) leading to the water intake point;

- 10 is an indicator that needs to be added as a stock.

Please note that the quality of the supplied pressure is also affected by the inner surface of the pipe, that is, if there are roughnesses, then the supply pressure will be lower.

What should be the diameter of the casing

The optimum pump diameter should be at least 76 mm, assuming that it is lowered into the casing with a diameter of 90 mm. However, for private houses, the best option for the well channel should be at least 110 mm, respectively, similar indicators of downhole pumping equipment will be no more than 100 mm for centrifugal and no more than 90 mm for vibrating.

Remember that wells with a small diameter silt very quickly, so it is advisable to carry out regular maintenance.

Dear readers, if you still have questions on the topic of the publication, write in the comments under the article. Our team will be happy to help you figure out all sorts of nuances.

Read also:

Best fecal pumps

The best pumps for wells

The best pumping stations