Before applying the decorative layer, the base must be properly prepared. In this case, one must not only know how to clean it from dirt, remove rust, but also how you can degrease the surface. The last step should not be abandoned. This will create a high quality decorative layer. At the same time, you need to know what tools are used in order to choose the right ones for specific conditions.

Read in the article

- 1 Is it worth degreasing the surface: the purpose of the operation

- 2 Traditional products used for degreasing

- 2.1 Chemical organic solvents

- 2.2 Alkaline degreasers

- 2.3 Emulsification formulations

- 2.4 Water based degreasers

- 3 New methods of cleaning surfaces

- 3.1 Electrochemical and ultrasonic degreasing

- 3.2 Sandblasting

- 4 How can you degrease a surface of different materials: recommended compositions

- 4.1 Metal

- 4.2 Plastic

- 4.3 Glass

- 4.4 Wood

- 4.5 Other coatings

- 5 Features of degreasing surfaces depending on the type of finish

- 5.1 Painting

- 5.2 Gluing

Is it worth degreasing the surface: the purpose of the operation

The degreasing process removes contaminants and grease from the surface that may be present on the surface to be treated.

Their presence is undesirable, since:

- It impairs the wetting of the surface with the coloring composition, and it falls worse on the base.

- The film formation process slows down.

- The mechanism for the formation of a decorative coating is violated.

Substrate contamination may vary. If there is up to 1 g of fat residues in one square, the base is considered to be slightly soiled. If the residual fat is in the range of 1-5 g, the level of contamination is considered medium, more than 5 g - increased.

Traditional products used for degreasing

Traditionally, before preparing the surface for subsequent processing, special compositions are applied to it, allowing you to get rid of fatty films. Such products can be applied to a certain type of surface. In order not to be mistaken with the choice when carrying out work at home, it is worth getting to know the main varieties.

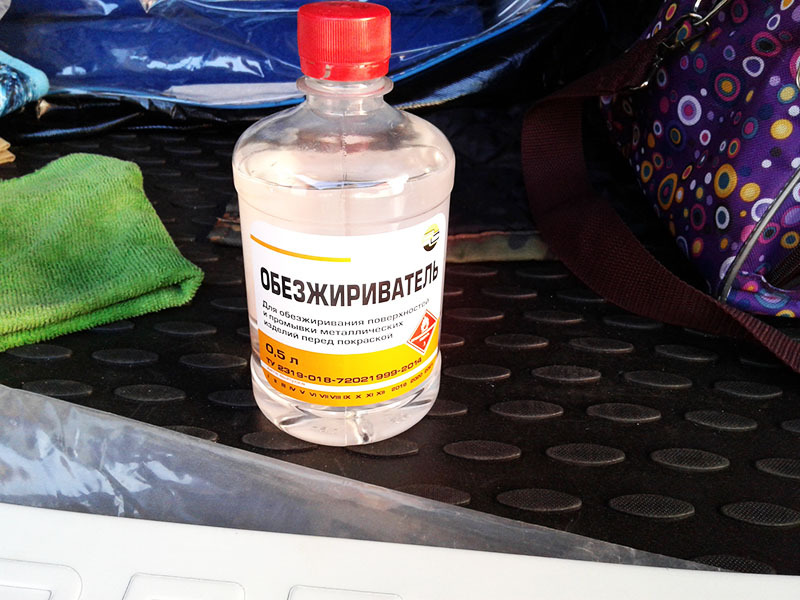

Chemical organic solvents

Similar compositions are obtained as a result of oil refining. These agents are classified as aromatic hydrocarbons, alcohols or esters. They have an affordable cost, are effective and easy to use, and therefore are widely used. With organic solvents, grease and hydrocarbon residues on the surface can be removed.

Attention! Chemical solvents can be flammable and toxic. They are used to treat small areas due to their high evaporation rate.

Alkaline degreasers

This group includes most detergents containing alkali. With their help, they not only degrease the base, but also additionally clean it from the existing dirt. In this case, oil films and fat are partially removed. However, alkali provides a number of reactions that accelerate the cleaning process.

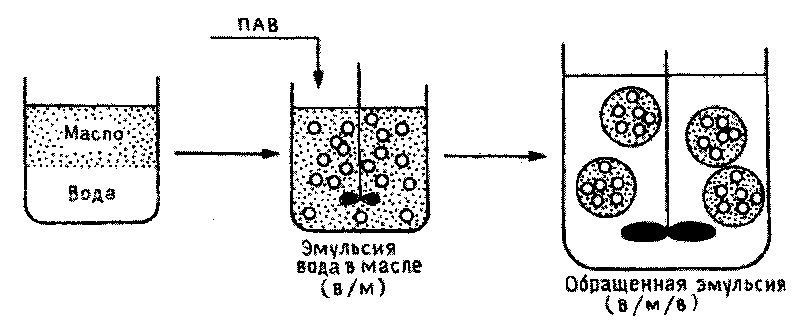

Emulsification formulations

This category includes emulsion cleaning compounds based on aqueous dispersions of organic degreasers. They contain an emulsifier with high surface activity. The presence of this component ensures the formation of a dispersed system in which drops of organic matter are evenly distributed over the water volume.

Thanks to this structure, it is possible to:

- reduce the toxicity and fire hazard of the composition;

- increase the evaporation time;

- simplify the application process.

Emulsion formulations easily penetrate the pores. The surfactant substances included in them emulsify the particles and do not allow them to return to the surface. The formulations are widely used for treating large surfaces, dealing with traces of hydrocarbons, oxide films and carbon deposits.

Water based degreasers

By itself, water does not fight fat stains well due to its high surface tension and the inability to emulsify fat.

The use of an aqueous solution as a degreasing agent is resorted to if:

- the acidity level is increased;

- the solution can be heated to 55-60 ° C;

- surfactants are present.

Due to their peculiarity, aqueous solutions are able to cope only with low and medium pollution. However, they are safe to use.

New methods of cleaning surfaces

More modern surface cleaning methods can be used instead of traditional products. They allow you to achieve better preparation of the base and significantly speed up the process of degreasing the base.

Electrochemical and ultrasonic degreasing

Electrochemical degreasing allows you to cope with fairly thin films of fat. Cleaning is carried out in special baths that ensure the recovery of hydrogen ions under the action of a current in the form of bubbles on the electrode. This facilitates the separation of oil droplets from the surface.

Electrochemical degreasing is widely used for the processing of thin-walled steel products and springs. Degreasing is performed for 5-8 minutes at the cathode, and then 1-2 minutes at the anode. If parts made of aluminum, copper or zinc alloys are to be cleaned, the procedure is carried out only at the cathode.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

"Electrochemical deposition is not used to prepare surfaces with complex shapes due to the low scattering power of the electrolyte."

Additional heating contributes to the intensification of the process. In this case, one should carefully observe the technology for performing work and control the amount of foaming agents.

In ultrasonic degreasing, the workpiece is placed in a special bath filled with detergent and subjected to ultrasonic cleaning. The activator included in the working solution provides high-quality cleaning of surfaces of any shape. Oil films are removed as a result of cavitation processes. Bubbles penetrate underneath the film, peeling and breaking down contaminants.

This processing method is used to prepare important parts, tools, jewelry. As a result of acoustic exposure, not only fatty films are removed, but also traces of corrosion and all kinds of pollution.

Sandblasting

This method involves supplying sand particles to the surface to be cleaned using a compressed air stream. As a result, it is possible to get rid of rather complex contaminants, including scale, traces of corrosion processes, and various grease contaminants.

As a result of sandblasting, hardening is formed on the metal surface. The characteristic deformation of the surface and the formation of a special relief with numerous small grooves increases the adhesive properties, ensuring the formation of a high-quality decorative coating.

To carry out the operation, you must have a special sandblasting machine. The compressor included in its composition provides air supply under a sufficiently strong pressure. Thanks to this, it is possible to provide surface treatment with abrasive particles.

How can you degrease a surface of different materials: recommended compositions

The process of degreasing the base largely depends on the material from which it is made. For each type, the most suitable composition is selected, which significantly improves the final result. It is worth figuring out in advance what is the best way to process a particular product.

Metal

Alcohol, acetone, white spirit and gasoline can be used to degrease the metal base.

To get the desired result, metal:

- cleaned with a grinder or sandpaper to remove rust, dirt, dust;

- wiped with a cloth soaked in solvent.

If the product is small, it is placed in a solvent entirely and left for a while.

Plastic

Plastic substrates do not adhere well to other materials. This significantly increases the requirements for the process of their preparation. For degreasing plastic, acetone or liquids containing alcohol are most often used.

Advice! The wettability test will help to check the selected composition for the possibility of use. This should be done on an inconspicuous area.

Glass

Glass surfaces are not afraid of aggressive substances. You can use regular alcohol or a universal solvent to prepare the base. For glass cleaning, it is worth using specialized formulations.

Wood

When preparing a wooden base, the top layer is removed from the surface. If this is not possible, the surface is cleaned with sandpaper or a plane is used. Cleaning is carried out until complete removal of oil films is achieved. Plane processing is carried out immediately before gluing the individual elements. Removing a layer of sufficient thickness eliminates the need for additional funds.

Other coatings

Painted surfaces are first mechanically cleaned. The required level of roughness is provided. After that, the coating is degreased using solvents that cannot harm it. Most often, preference is given to alcohol-containing liquids.

If it is necessary to prepare ceramics, the choice is made in favor of acetone, alcohol and a number of other liquids. For concrete, perchlorethylene is the best choice. After applying the composition, the surface is thoroughly dried, since there is a lot of moisture inside such materials.

Features of degreasing surfaces depending on the type of finish

The procedure for degreasing the base largely depends on the type of subsequent processing. If the car body is to be painted, the work is carried out using the same technology. If you need to glue the individual elements - on the other.

Painting

Before painting, degrease the base in the sequence shown in the table.

| Illustration | Procedure |

| The necessary tools and means are being prepared. For application of the composition, it is preferable to use a polypropylene wipe. Paper should be discarded, since they are not able to provide a sufficient degree of cleaning the base. |

| Using a spray gun, the composition is applied to the surface. In this case, you can notice all the defects that are on the base. |

| Using a napkin, the composition is carefully rubbed into the surface. As a result, the existing dirt, including oil and grease stains, is completely removed. Time is given for the complete evaporation of the composition from the surface before applying the paintwork |

The process is described in more detail in the following video:

Gluing

If gluing of individual elements is planned, the surface must be degreased. The composition is selected depending on the material of the parts to be joined. The degreaser is applied to a dry surface, as the solution used in contact with water may impair the result. To test the effectiveness of the chosen method, a drop of water is applied to the surface. If it spreads freely over the base, then there is no fat on the surface.

Share in the comments whether you had to degrease the surface, what material and what tool did you decide to use.