People who at least sometimes engaged in repair and installation works are aware that the clip may be necessary in the most unexpected moment. This is the first device that comes to mind when you need to quickly fix leaking pipes. Indeed, the imposition of the clamp is a temporary measure, but sometimes necessary. It is possible that due to circumstances it can not be bought right now, in addition to solve the problem approach even a simple clip wire. Therefore, we need to do it yourself.

Design features of the product

Clamp - simple and effective device having a typical mass variations, but essentially, they all have similar structural characteristics. The difference is represented as shapes device fasteners. Their use is most common in the field of installation and repair of piping systems, this causes another characteristic feature of the design. For better fixation and sealing, in a product often has a rubber gasket.

With regard to practical use the product in question, we can say that without them practically impossible to implement a pipeline-quality fixation, both horizontal and vertical.

The range of this type of device starts with the most simple one-way products that represent a threaded bolt. Next, it proceeds variations that differ not only greater complexity of construction, but also in size (this It should be understood the maximum pipe diameter to which a particular product can be used) and the target appointment.

The most common problems whose solution helps clips:

- Removal of cracks in the pipeline systems. Depending on the type of product, you can even block rather large damage.

- Fracture of the pipe - not often, but it is a serious problem. For the most part, her faced by those engaged in installation and repair of pipelines professionally.

- Also, if necessary, removing the "fistula" water pipes, clamps again widely used. In such a situation it is necessary use a soft substrate.

Note! If the pipe is in respect of which the repair is carried out, is a means of transportation of corrosive liquids, the You need to use this type of fastener that is capable of transferring these specific conditions operation.

- Particularly for pipes of steel, the product can help reduce the risk of leaks caused by corrosion. Often there are situations that it damages the metal so much that a leak could occur at any moment.

The market is saturated with all sorts of configurations clamps of different manufacturers. Factory production, in addition to the professional manufacturer also provides a guarantee of quality. After all, the products are made in accordance with GOST. The reason for such a government regulation of quality, with high collars role in maintaining the integrity of the structures in which they are applied. Based on this, the question arises whether to do on the steel pipe clamp his hands.

Is it worth doing clamps his hands, and what mistakes can be admitted

The clamp is seemingly a simple device, which does not differ any in understanding the difficult characteristics. There is a risk associated with the manufacture of improvised collars depends on how much a person confident in his abilities, and that can be applied whether the clip in the given conditions.

For example, the heating pipe rusted badly given flow. Corrosion portion on the damaged site has sufficiently broad area. If manufactured properly clamp, inappropriate required size, after it attempts to install the situation can only get worse.

Based on this, of course, you should always have on hand clamps of different modifications and sizes factory production or when the problems with the pipeline immediately requesting repairs service. Unfortunately, neither the first nor the second variations often are not feasible. Leak no plans, while its origin is not regulated, and have in place clamps all configurations are not given the opportunity.

In the event of leaks, you need to take immediate action. And it is for this purpose can be made with your own hands a collar that will allow time to resolve the problem in its entirety.

The simplest clamp

In the absence of specialized tools and materials, such as grinders, drills, sheet metal, and the like, you can resort to the simplest, but at the time to solve the problem option - make a piece of clip wire. It will help to quickly eliminate leaks and quietly wait for the help of experts:

- The first thing to do is to find a tape or adhesive tape, a piece of soft enough to bend, but a solid wire and a piece of rubber (eg, burn).

- The following apply rubber moiety on the pipe at the place where the leak occurred, after which it is pressed tightly maximum wire by winding it.

Important! When winding wire, special attention should be paid to the edges of the next clip.

- The resulting patch, for greater reliability, tightly zamatyvaetsya adhesive tape (tape or tape).

Such a product made with his own hands, do not require time-consuming and thus help to avoid potential major problems.

semi-professional version

Described earlier example of manufacturing the wire clamp, it is "urgent." But if the production of the product does not require haste, and available tool, you can build yourself a pretty good version of the product. This already can serve for many years.

required tools

To begin, you should understand what tools you will need:

- Maul hammer or light;

- A drill and drill bit (Ø 6 - 8 mm);

- Bulgarian or special metal cutting shears;

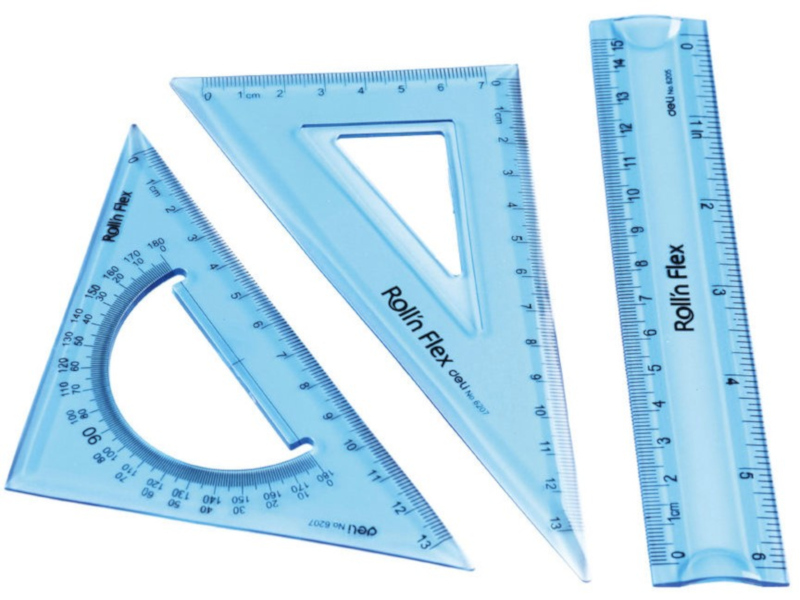

- Measuring instruments - a ruler, vernier caliper;

- Wrenches, pliers.

materials

For the manufacture of a collar that can carry heavy loads need:

- The plate of metal, of moderate thickness, preferably up to 1 mm. Do not use steel of greater thickness, as it will not only be difficult to bend, but it is not enough will make a tight connection;

- A rubber strip, its thickness should be about 3 mm;

- Bolts, nuts (Ø 6 - 8 mm). It is desirable to have a washer and them.

manufacturing algorithm

For the successful production of a collar with his hands, does not need special powers in this matter, but some basic skills is still needed. According to the advice of experienced plumbers, work should proceed in the following order:

- The process begins with the measurement of the damaged portion, then cut out of steel plate of appropriate size. The size of the plate must take into account not only the length of the damaged section of the pipe but also its circumference (after size, thereto is added 5 cm).

- On both sides of the workpiece with pliers bent "ears" of the future fasteners (eventually they should be perpendicular to the main part of the metal strip).

- The "ears" have to drill the holes for the fixing bolt.

- Next, cut a strip of rubber having a width which must be less than the circumference of the damaged pipe.

It will be appreciated! If a manufactured collar is small (less than 6 cm), the "ears" can be a single hole in the center of the fixing bolt. If it is, it is preferable to make them more than 2-3.

Mounting

Once the product is almost ready, you can proceed to install it, it will be shutting down.

- Mild steel plate by pressing the envelope around the tube having a diameter similar to that which has damage integrity. Ultimately, the ears should coincide.

- Attention! If you run a bend unevenly, it can cause problems with the installation of a fixing bolt.

- In place of leakage is applied a prepared piece of rubber, after which it is set on top of a steel plate. Before proceeding to the installation of the metal element, it is necessary to straighten a bit. This is done in order to simplify the process of installing the pipe.

- And so, if everything was done correctly, between the "ears" will be a distance of a few centimeters, and can pull together with a screw. Upon reaching a sufficient pressure on the product pipe flow ceases.