House draft-free, long keeps warm in winter and cool in summer - is a reliable material basis of the family comfort. High-quality insulation can reduce heating costs and air conditioning. A relatively new method of insulation, which is used in the last century - a spray foam insulation. The method allows to achieve a perfect seal surfaces and joints of building structures. Environmentally friendly coating, if necessary, can be removed without much effort.

types of coatings

In the civil engineering are used two main types of foams for thermal insulation: Based on UF foam and polyurethane foam.

Penoizol

Penoizol refers to the group of expanded plastics and after hardening forms a fine mesh maloupruguyu spatial structure. Chemical-based plastics are urea polymers. Penoizol comes in the form of:

- a liquid composition for spraying;

- molded flat plates;

- granules to fill the voids.

Penoizol perfect for warming frame structures. He actively foams and fills the gaps between:

- inner and outer walls;

- sheet metal panels (gypsum plasterboard, plastic, OSB) and the wall;

- roughing and finishing the floor.

Progressive material widely used for thermal insulation of pipes for various purposes.

Its main advantages are:

- High performance coating;

- resistance to temperature and moisture;

- long service life;

- malogoryuchest;

- elasticity and resistance to deformation.

He is not subject plesneobrazovaniyu and unpalatable to rodents. Like other foam material, it perfectly absorbs noise and dissipates vibration.

Polyurethane foam

Foamed polyurethane forms during solidification structure with closed cells. This increases the strength of the material as compared to conventional construction foam. It is applied a layer of 5-10 cm, has good adhesion to base materials:

- wood;

- brick and stone;

- metal;

- plastic.

Due to the closed form microcells it practically does not absorb liquid and itself serves as a waterproofing agent. It is used both outside and inside buildings.

The main advantages are penoizol:

- low specific weight;

- high fluidity in the liquid state and foamed, ability to fill cavities and gaps of any shape and width;

- low permeability to vapors;

- biological stability repelling mold and rodents.

Have a material and negative: for its use have to buy a special bottle and container.

Polyurethane foam

Budget method of insulation is the use of a conventional mounting construction spraying foam for thermal insulation of walls and ceilings. This can give economic benefits at warming the relatively small volumes and areas, such as the repair or minor remodeling. If we are talking about the building as a whole, the savings quickly come to naught. Assembly foam is often used for mounting sheet of solid foam insulation for filling joints and gaps therebetween.

The market offers a special brand of foam with high adhesion, specifically designed for fastening sheet materials. With their help, insulation of floors and walls of the building construction foam is quick and filling of joints - securely.

Thermal insulation paint

In addition to the expandable material, there is also another liquid heat insulator - ceramic paint. It is applied on stone, brick, foam concrete surfaces as a complex coating, which serves to:

- finish;

- insulation;

- proofing.

The main purpose of this paint - this moisture insulation. The effect of warming is a companion. To achieve insulation effect, commensurate with a 20 mm layer penoizol such paint will be applied at least 10 layers. Paint is perfect for a vapor barrier complex joints of building structures that are difficult to protect from moisture in other ways.

Myths about the harmfulness of foamed plastics

Conspiracy theories and unscrupulous advertisers competing classes for thermal insulation products are often spread rumors about the terrible damage to health foamed plastic.

If the deal without hysteria and exaggeration, polyurethane foam does have one property, carrying a potential threat.

On combustion it may form toxic volatiles based on formaldehyde resins. During a fire, it may be an additional risk factor for those who did not leave the burning room.

During the application of foaming composition also allocated certain amount of inert gas and other chemical compounds.

However, after the complete solidification of the foam covering his entire period of operation no harmful emissions occurs. Full film surrounding each micro cell, chemically inert and impermeable.

Summarizing, we can say that the foam blanket is perfectly safe during operation.

During the application must comply with all the safety precautions listed in the manual:

- use only serviceable equipment;

- eliminate the use of open flames and high temperature heaters during application;

- wear personal protective equipment: respirator, gloves, protective overalls with a hood and thick shoes;

- when working indoors ensure its ventilation

- not to use the room to find the people in them to complete solidification of the composition (usually 24 hours).

Of course, during the operation of the expanded coating in the house need to establish and consistently comply with fire safety regulations.

Popular Equipment, cost and specifications

High-performance universal installation for spraying foam covering professional level there are hundreds of thousands of rubles. Their purchase makes sense if you plan to open a business on the insulation. At one house, they will not pay off.

consumer level devices are cheaper, they are divided into two classes:

disposable

It is assembled at the factory setting with the charged components. its advantages

- minimum provisioning and ease of use;

- low price;

- after use is no need for washing and conservation.

The disadvantages are:

- a fixed amount of the composition and thus covered during the use of the area;

- requires a precise calculation of purchased packages - may not be enough or stay extra.

It makes sense for beginners masters who do not want to waste time trying to deal with the setting, dressing and taking care of reusable setup.

rechargeable

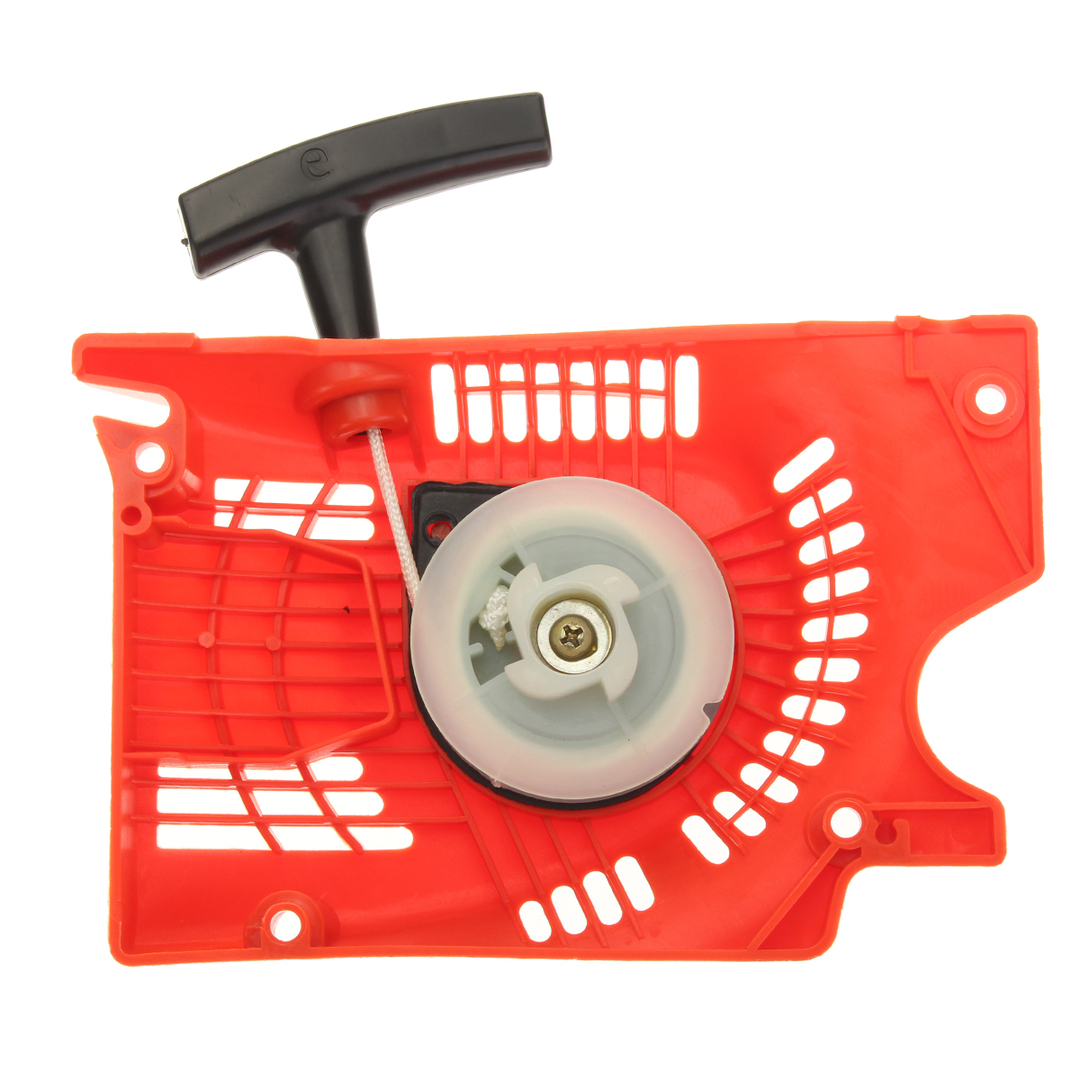

This is a complete system for applying viscous coatings having, unlike professional limited performance and service life. They allow you to choose the type and density of the mixture in the cylinders is strictly charged the needs of its amount

ProtonHome

- Popular rechargeable installation costs by 25 TR

- allows the sprayed coating of any density,

- Productivity- 2 kg of the mixture per minute, which corresponds to 25-30 m2 at a thickness of 2 cm.

- cost per square meter coverage -. about 560 rubles, the lowest among peers.

- Cheapness turns into lack of small adjustments to the process parameters.

- A good choice for beginners.

Air-Light

More productive (up to 4 kg of the mixture per minute) universal rechargeable installation, it allows to work both with embedded balloons and pick components from the 100- and 200-liter drums. It is equipped with a frame and wheels for ease of movement on site. It is reasonable to acquire, if anticipated large volumes of foam insulation

Cost - from 80 thousand. rub.

Foam Kit 600

Kit for applying the coating 56 m2, disposable, preconfigured.

It is worth about 35 thousand. rub., the kit includes everything you need for the application of the composition charged into the cylinders, including a removable nozzle gun and protective gloves.

The process of warming

Coating the foam with your hands quite a force handyman skills with initial spray painting. When working with domestic entry-level units are usually done by one person. When installing battens and when working with high-performance devices with long hoses to carry them, and move containers with components need an assistant.

Getting started

Before proceeding, it is necessary to prepare the surface for coating. It is necessary to remove old wallpaper, paint and anything that might interfere with the foam adhere to the surface.

Next, in steps of 50 cm is fixed to the wall vertical guides - wood or metal profile. They are designed for attaching a finishing material - plasterboard lining or another. If the decoration layer will not, guides are not mounted and sprayed foam continuous layer.

All work on the construction of communications - electrical and piping - must be completed before the beginning of the deposition. Wire is recommended to lay in the corrugated plastic or metal sleeves.

Before the start of covering the walls with foam should also make sure that the hoses and cylinders no air bubbles.

fill

First filled with foam all joints, junctions, gap and the cavity. So you can get rid of unwanted voids left between the designs and finishing materials to the early stages of construction. While insulating cavities remaining between the walls of the polymeric foam, they are doing a few holes. On one side of the foam is blown when it is struck from the pilot holes from the opposite side - the blowing is stopped.

If set crate, first place also hosts its contiguity to the wall.

The application of the foam on the wall is performed in neat sweeping movements. Vertical surfaces coated upwards.

If the pipes are covered, they should be before the start of works to protect against corrosion, cleaning, degrease and causing corrosion-resistant coating.

After application and hardening of the foam on its outer or inner wall can be plastered and then painted.

How to choose a material

The market offers a wide range of materials for insulating foam. European-foam insulation, intended for wall, ensures high quality, but a high price is different. Domestic manufacturers have mastered the production of good licensing structures and materials own development, at a much lower price to ensure a decent quality of insulation and a guaranteed period service. Experts identify such manufacturers as

- "Dow-Izolan";

- NVP "Vladipur";

- "Khimpostavschik Don";

- "Elastokam";

- CJSC "Urethane";

- "Khimprom".

Their advantage over anonymous Chinese crafts - precisely known composition and quality control at all stages of production.

Choosing foam, designed for thermal insulation of external walls, you should check whether a particular material is recommended for outdoor use, whether it corresponds to the density of existing facilities and the ultimate theoretical density foam.

And if the savings on hardware more or less reasonable - it is useful only once, at the material just is not worth saving.