Each gas boiler needs a few key nodes, which will monitor the unit for proper operation. In case of any deviations triggered different components, and installation simply ceases to function. But this should be understood as a check valve solenoid gas boiler, a thermocouple or any other component. After knowing about the fault, in most cases it is possible to remove yourself.

Thermocouple

This device is one of the few that can measure high temperature. It is both a simple and yet reliable. A thermocouple made of two wires of different metals which are connected at different points. All this makes it possible to use it for different purposes. The main drawback can be called an error of one degree. Simple layman it seems insignificant. But for such devices, many believe these figures simply gigantic.

The apparatus is used as a fuse. It measures the temperature in the warmer. If it starts to drop rapidly (say, for whatever reasons, the fire went out, or there were problems with chimneys), activated system in which a signal is supplied to the solenoid valve and gas terminated. Therefore, if this does not work component - equipment incapacitated.

Procedure for verification:

- The thermocouple has two closure, the first of which is heated igniter, while the second is fixed to the solenoid valve. It is necessary to separate the device from the boiler, be it conventional or condensing having a three-way valve.

- Then ensure continuous flame. It would be the best candle.

- Heat the tip of the flame at a distance of 1 cm. Just be careful, because the heat can reach up to half of the body.

- We take the tester and turn it to millivolts. One probe is placed on the body and on the second output terminal.

- After half a minute serviceable thermocouple EMF will in the range from 17 to 25 mV. If the indicators are normal, then the problem is a broken system can be different.

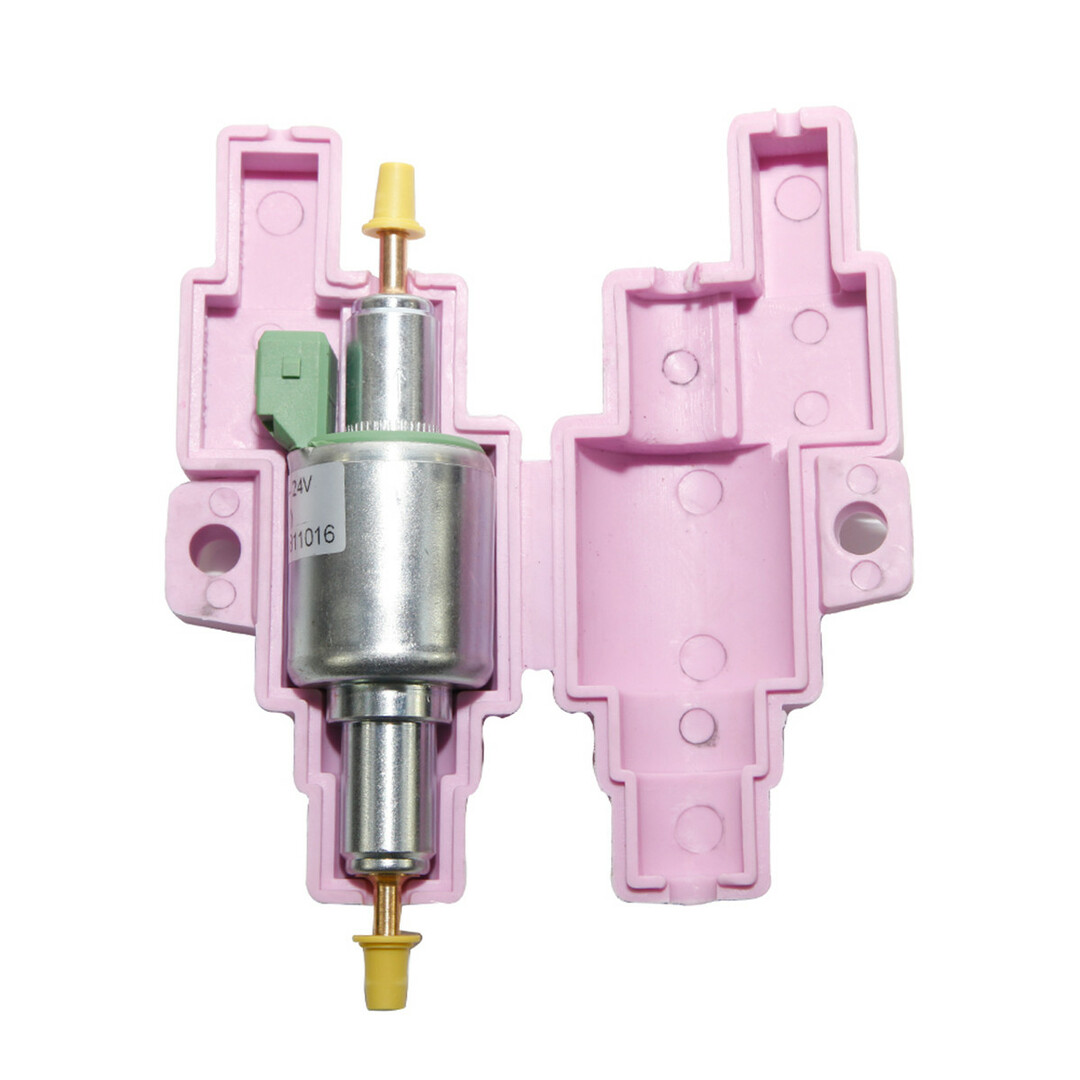

Solenoid valve

The solenoid valve is a shut-off valve, which directly affects the safety of the unit. Mainly it is established that in the event of a problem, he closed the supply of fuel. Emergency situations in the operation of gas heating may be due to various factors:

- pressure drop fuel;

- shortage of liquid in the system (it is possible to check the joints, the three-way valve and the pipe);

- deterioration of traction;

- leak of gas.

Each of the above-mentioned problems is dangerous to human life, and therefore the further operation of the system is not allowed. That is why the solenoid valve is activated. Its original position - it is open. To close it is supplied electrical pulse coming from a thermocouple installed in the flame in the combustion chamber or flue.

Immediately I must say that this element comes from standing is extremely rare, as it has great potential for use. Despite this, though there are moments.

Check the operation of the valve in two ways:

- Fire. Used thermocouple is replaced by a new one. Turn on automatic button. Further, the igniter is ignited and the fire is brought to an end a thermocouple. In this equipment should work.

- Instrumental. The sensor is removed from the housing and inserted repair contact. It is energized from 3 to 6B. If the solenoid valve in the order - automation work. Otherwise, you need to replace the element.

ignition transformer

This element supplies the burner current discharge (spark), which is required for ignition of fuel. Also other elements, directly affecting the operation unit component may also fail. As a result, all the equipment will work, but the fire did not appear as there is no source of ignition.

How can I quickly check the ignition transformer gas boiler performance? Simply. We need to do some simple movements:

- Through a special window to see if the discharge goes or not.

- By means of a tester strain emerging from the controller during ignition attempts. Considered a normal figure that falls within the interval from 187 to 235V.

- In case of problems need to disconnect the power from the transformer and plug it back.

- Check again.

In any gas boiler, a plurality of sensors and safety elements permitting to monitor the correct operation of the unit. In the event of situations that clearly threaten human lives, works completely disconnect mounting system.