- Why do I need an electric gas cooker?

- Gas cooker with electric ignition -

- options How to determine if the system is out of order?

- We perform diagnostics

- We deal with the electronic unit

- High-voltage module

- What else can break?

The ignition system is not an obligatory part of the gas stove, but it is very convenient. Electro-firing is safer than other methods, and besides, the owner does not have to constantly think whether the matches are left at home or not. But any system sometimes fails, and you either need to contact the master, or repair yourself. Repair of gas stoves with electric ignition - what is it? Let's discuss this.

to the contents ↑Why do I need an electric gas stove?

As the name implies, the system is needed to turn on the stove. This device is useful for those who often cook on the gas hob, besides, does not like or is afraid to use matches. The ignition allows one easy movement to turn on the gas in the oven or on the burner.

Old plates were made without built-in ignition. At their owners the process looked like this:

- A valve was opened on a cylinder or pipe.

- They lit a match.

- Bring it to the burner.

- Simultaneously turn the knob corresponding to the same burner.

Important! Strangely enough, even then not everyone could use matches. Fires arose not only because someone forgot to turn off the stove, but also simply from an unspoiled match that fell to the floor or to the tack.

Gas or gasoline lighters were also uncomfortable. It was much safer to find a piezo lighter. Most of the owners of old gas stoves use it. Modern models, however, most often have a built-in system - an electric ignition of a gas cooker.

to content ↑Gas cooker with electric ignition - variants

In modern gas cookers there can be different systems of electric ignition. They are divided according to the type of control:

- mechanical;

- automatic.

This or that option depends on how the transformer is connected.

Mechanical ignition

It is a button on the front panel, next to the knobs. This button simply needs to be pressed by turning the corresponding switch.

Thanks to this simple movement, the capacitor is charged, then discharged, the circuit closes, a spark passes, which ignites the burner. In this case, a single spark arises.

Automatic ignition

There is no button on this plate. Just turn the switch, pushing it lightly. Unlike mechanical ignition, with automatic there are a lot of sparks that skip at a frequency of 50 Hz.

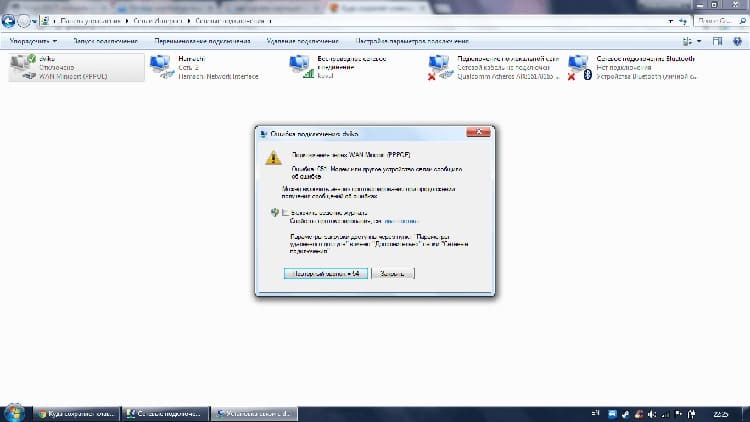

to the contents ↑How to determine if the system is out of order?

And now one moment you turn the switch, you hear that the gas starts to come out, and the sparks do not. What to do? First, check all the burners. If you everywhere see the same picture - the electric ignition of the gas stove is clearly in need of repair or, at least, in maintenance.

There may be other signs: the

- spark has passed, and the burner does not ignite;

- there are continuous clicks;The

- system constantly gives sparks, even when the burner is off;

- handle released - and the ignition does not turn off;

- when the plate is turned on, automatic protection in the shield is triggered;

- no one knows where the water appears under the handles after cleaning.

If the electric ignition of the gas cooker does not work on all the burners, a more thorough diagnosis is needed. It is not excluded that the slab or some of its parts will have to be dismantled.

Important! Before starting any manipulation of the ignition, the gas must be blocked.

to the contents ↑We perform diagnostics

Before we sort out something, we need to understand what exactly happened. To do this, it is enough to perform some fairly simple actions.

Burner problems and not only

You have already verified whether other burners are ignited from the ignition system. Now try to do the same, but with matches or lighters. Start with the problem burner. You will see one of the following pictures:

- The gas burns evenly over the entire circumference.

- The gas burns only on one side.

In the first case, the burner is, of course, serviceable, and the cause of the malfunction must be sought in the spark plug, transformer or the current paths of the ignition system.

If the fire appeared only on one side - most likely, the ignition system is working. In this case, two options are possible:

- The burner is deformed for some reason. Do not try to fix the hotplate yourself - this is a dangerous thing. The best way is to call the master, and he will change it in a few minutes and the minimum payment.

- The clogger is clogged. Clean the nozzle and replace the divider. Of course, all this must be done by turning off the gas.

Switched switching

The cause of the malfunction may be the improper operation of the "electrode-switch" connections. They are connected in parallel. The electrodes receive voltage from the same ignition module, but they are switched on by means of different switches.

It makes sense to try this option:

- Turn and push the handle, as you normally do, including the burner.

- Without releasing the handle, turn exactly the same way.

If the gas is on fire, look for a cause in the commutation or switch. This is where the repair of the gas cooker with the electric ignition is required.

If sparks fall constantly

The reason that the electric ignition of the gas cooker is constantly sparking can be several:

- dirt;

- dampness;

- fat;

- oxidation of switch contacts;

- deformation of the contact switches.

It's not difficult to cope with water, grease and dirt. It's enough just to clean the switches and what's under them. Oxidation of contacts is also a solvable problem. But with deformation, it's much more difficult to handle, switches have to be changed.

Important! Inspection of all the elements must be done by disconnecting the plate from the mains.

to the contents ↑We deal with the electronic unit

The clippers are clean, the switches got rid of the fat, but there is still no ignition? I'll have to deal with electronic circuits.

The electronic unit breaks down quite often, especially at plates of the European manufacture. The cause may be voltage in the power grid that does not meet the manufacturer's requirements - for example, 200 V instead of 220 V. If the system failed for this reason, it is almost impossible to repair the gas stove with the electric ignition, it is necessary to completely change the ignition unit.

But there are other reasons:

- aging of parts;

- combustion of individual elements;

- dirt.

What elements are included in the system?

If the ignition does not work on the gas stove, you will have to carefully consider not only the details of this system, but also the parts of the plate that are in contact with it. And the first thing to do is to inspect the candle.

Candle

The candle is a small white pin that is located under the dissector. If there is a problem with this element, there is a spark, and the fire on the burner does not appear. In this case, it is sufficient to clean the areas of the candle and the burners that contact each other. To do this:

- Remove the sparger.

- Wipe the spark plug and the burner parts in contact with it with a cotton swab dipped in alcohol.

- Install the diffuser in place.

After cleaning, check the operation - the spark must go clearly into the burner opening, that is vertically.

Important! You can not check the results of work with the burner removed.

to contents ↑High-voltage module

It is located under the working surface of the plate. The scheme is not very complicated, and for someone who understands even a little bit about radio components, it is not difficult to deal with it in order to repair a gas cooker with an electric ignition.

The module consists of the following elements:

- current paths;

- transformer;

- capacitor;

- diode;

- transistor( switch);

- resistors.

In some expensive modern models there are still a thyristor or triac that allows you to control the spark with the help of a chip. The process, which looks like a switch with the simultaneous click on it, actually looks like this:

- Voltage is supplied from the transformer to a capacitor mounted in its housing.

- It is from this that the capacitor is charged.

- Voltage from the capacitor goes to the triac.

- A spark is formed, which is fed into the hole in the burner.

Running tracks

Start diagnostics from the conductive tracks. The path should look like a continuous silvery strip on which lacquer is applied. Lacquer is needed in order to protect the conductor from moisture, dust and other troubles. If the track is solid, and the varnish is scraped - restore its layer. For this, any varnish, even for nails, will do.

If you see a layer of carbon, you will need:

- skins( zero);

- alcohol.

Strip off the place where the deposit has formed, with a sandpaper. Degrease it with alcohol, and then cover with varnish. If the tracks themselves broke, they can be restored by soldering the jumpers. This will be the entire repair of the gas stove with the electric ignition.

Resistors

Resistors need to check how much they match the specified denomination( you can find out by marking - numbers or color strips).Burned detail is easy to determine - it often becomes completely black.

Important! In some cases, you can put more powerful elements, but do not abuse it.

You can check the operation in two ways:

- by calling an ohmmeter;

- putting in place of the "native" another resistor.

Important! Since for testing it is necessary to separate the part from at least one side, it is better to have at hand new resistors with the same marking. Most often in gas stoves, resistors are applied at 3.9 kΩ with a dissipation power of 0.5 to 1 W.

Condensers

Capacitors inspect visually. If they are out of order, it is usually noticeable. Such details have the property of swelling, and under adverse conditions - even bursting. As for the transformer, it is checked by an ordinary tester for the presence of a cliff.

The capacitor is selected according to two parameters:

- capacitance;

- voltage.

Transformer

The most vulnerable part of any device. The transformer of the electric gas ignition system of a gas cooker, like any other, has two windings:

- primary;

- secondary.

Primary is two half-windings with different magnetomotive forces at the ends. What does it mean? The thyristor control electrode alternately has positive and negative charges. With a positive pulse, the thyristor opens, the current increases to the nominal value.

The output voltage is generated on the secondary winding. It leaves about 10 kW.The process is repeated at a rate of 1 spark per second. The secondary winding consists of two windings with parallel excitation, which is fed to the candle.

To test the transformer, the tester or multimeter must be set to the minimum resistance position.

Important! The burnt out element is best replaced simply. If you want to wind it, of course, you can rewind, but this requires accuracy - the number of turns must be strictly defined.

Thyristor

This part is checked for conductivity. It is put into the resistance position and checked in several places:

- voltage between the control electrode and the anode;

- voltage between anode and control electrode;

- voltage between anode and cathode;

- voltage between cathode and anode.

The absence of voltage at least on one site indicates that the part has to be changed.

to the contents ↑What else can break?

Problems and the need to repair gas stoves with electric ignition may be different. Here are a couple of reasons.

Button

If you have a cooker with a mechanical ignition - pay attention to the button. This detail is very important, because it is she who starts the circuit. On its contacts passes a standard voltage of 220 V. But contacts it from brass. If you are unlucky and there was a short circuit in the house - brass almost melted with a guarantee. You just need to clean up the contacts. At the same time does not prevent to ring the multimeter switch.

Combustion Control Scheme

This is usually a thermocouple. If you have already determined that the ignition system is absolutely working, but there is still no flame, check this sensor, since it is he who is responsible for the gas supply. If the circuit is burned, the gas supply is shut off.

This module has 4 or 6 outputs. The problem is determined visually or with a tester. The thermocouple must be replaced.

From this article you have learned all that is necessary to make the repair of a gas cooker with an electric ignition or at least to understand the causes of a malfunction of the combustion system. We hope you managed to correct the situation, and again you can easily prepare your favorite dishes.