The development of small business has revealed the need for entrepreneurs in various services and goods, including tools. One of the services is to determine the thickness of the protective and decorative coating on different surfaces. For example, it is necessary for buyers of used cars, with the purpose of revealing repainting of car elements, if the latter has been in an accident. Determination of the size of the coating is done with the help of a specialized tool - a thickness gauge. There are many manufacturers on the market that offer different devices with different characteristics from each other. Which one is the best? Which one to choose without overpaying the excess? We invite you to familiarize yourself and consider the models closer.

Contents:

- Thickness gauge of which firm to choose

- The best ultrasonic thickness gauges

- The best magnetic thickness gauges

- The best combined thickness gauges

- The best combined thickness gauges

- The best mechanical thickness gauges

- What thickness gage to buy

Thickness gauge of which firm to choose

Thickness gage -total thickness of the part or workpiece, as well as protective and decorative coating( primer, putty, mastic, varnish, paint andetc.).The tool allows you to determine the size of the surface layer without disturbing it.

The device is divided according to the principle of operation, purpose, measurement method:

- ultrasonic;

- magnetic;

- eddy current( electromagnetic);

- combined;

- universal;

- mechanical.

The review is based on the analysis of customers 'and device users' reviews, as well as on sales ratings in outlets.

The principle of the ultrasonic thickness gauge is based on the passage of an audio signal through the coating, reflection from the base, followed by a sensor recording. The range of error of the device is ± 3%.The defined coating size is from 0.08 mm.

The devices of domestic and foreign manufacturers are presented:

1. Megion( Russia)

2. TESTBOY( Germany)

3. LLC "IC Fizpribor"( Russia)

4. "Acoustic Testing Systems"( Russia)

5 TechnotestMarket LLC( Russia)

Corporate communications and the economic situation allow the owners of brands to place orders abroad.

The basis of the magnetic thickness gauge - the properties of magnets. The non-magnetic coatings applied to the magnetic base are measured. The calculation is made by changes in the force of attraction between the magnetic surface and the magnet of the device.

Magnetic thickness gages are presented:

1. Megaion( Russia)

2. ETARI( Taiwan)

3. AUTO-MAG( Poland)

4. Allsun( China)

5. Blue Technology( Poland)

Actioneddy current gauge is based on the creation of eddy currents in the conductive base. The Foucault currents, in turn, generate their own electromagnetic field, which is opposite to the primary one. The latter is produced by the coil of the device. The created secondary variable magnetic field is picked up by the tool, the thickness of the coating is calculated. Thickness gauge works stably only on conductive bases - ferrous metal, non-ferrous metals and alloys.

Instruments are represented by the trade-marks:

1. ETARI( Taiwan)

2. Megion( Russia)

3. KEEPER( China)

4. Horstek( Germany)

5. LLC "Control. Measurement. Diagnostics"(Russia)

Combined thickness gauges combine two methods based on the eddy current and magnetic principle of reading. This makes it possible to use the tool on magnetic and nonmagnetic bases.

Combined instruments are manufactured by many companies, including:

1. CEM( China)

2. ETARI( Taiwan)

3. ADA( Hong Kong)

4. Condtrol( Russia)

5. Megéon)

Universal thickness gauges are used to work with all kinds of bases( metals, polymers, glass, ceramics, concrete, wood, etc.) and determine the thickness of coatings from dielectrics, magnetic and conductive materials.

High-quality products are manufactured under the following brands:

1. Gradient( Russia)

2. TIME Group Inc( Russia)

3. Constant( Russia)

4. Elcometer( United Kingdom)

5. DeFelsko( USA)

The mechanical method is used in many industries, including machine building, metalworking, plumbing. It is necessary to take readings from the outside of the product.

Instruments are represented by the trade marks:

1. ZUBR( Russia)

2. Fit( Canada)

3. Matrix( Germany)

The best ultrasonic thickness gauges

Megion 19100

The tool produces accurate measurements of coatings in the range of 1200-225000 μm1.2-225 mm).It is used for materials that conduct and reflect ultrasound, for example, polymers, glass, ceramics, as well as ferrous and non-ferrous metals. Widely used in industry to control the thickness of various coatings.

Pros:

- Extended range of materials under study;

- Presence of the self-calibration function;

- Accuracy ± 0.1 μm;

- Up to 10 measurement modes;

- The function of storing the last 10 results;

- Ability to conduct more than 10,000 cycles;

- 12 adjustable measuring speeds.

Cons:

- Road for domestic purposes;

- The need for an additional operation is the application of a binder.

TESTBOY 72

Suitable for all types of non-magnetic surfaces( paintwork, non-ferrous metals, chrome).It is possible to measure the thickness of coatings on non-magnetic substrates( aluminum foil).Found application in garages and sales outlets to determine the coatings after accidents.

Advantages:

- High measurement accuracy at thicknesses of 0-1000 μm;

- Ability to work on forms with small rounding( 1.5 mm);

- Protection against atmospheric influences and solar radiation;

- Complete with a wire for access to remote locations.

Disadvantages:

- High price, does not justify investing for individual entrepreneurs;

- No self-calibration function.

UT-907

Used for controlling the thickness of metal, polymer and ceramic parts. Measurements are made with one-sided access to the surface. It is used in industry for work with pipes, tanks, cisterns and other products, whose surface is destroyed by contact with aggressive substances.

Advantages:

- is included in the State Register;

- Ability to identify delamination material;

- Defines local thinning;

- Identifies corrosion sites;

- Non-volatile memory for 1000 files;

- Single-wire interface;

- USB port.

Disadvantages:

- High price;

- A trained specialist is required for the job.

A-1207

One of the smallest thickness gauges. It is used to determine the thickness of the walls of various structures( metal and plastic pipes, boilers, ship hulls, etc.).It is used in almost all types of industry. Convenient for express tests.

Advantages:

- Small overall dimensions and weight;

- Possibility of express control;

- Verification;

- Duration of work on one charge - up to 25 hours;

- Operating temperature range -30 - + 50 ° C.

Disadvantages:

- High price;

- Specificity of application - large-scale industry.

TEMP UT-2

General purpose device. It is used to control the wall thicknesses of parts made of metal and non-metallic materials. Measurements are carried out in the process of manufacturing, repairing or operating products with or without coated coating.

Pros:

- Presence of built-in sample with reference thickness;

- Memorization of parameters;

- Memory for 4000 test results;

- Robust housing;

- Measurement time, no more than 0.3 seconds;

- Automatic shutdown.

Cons:

- High price for beginners.

The best magnetic thickness gauges

Megion 19200

A simple device for testing non-magnetic coatings on a magnetic base. Equipped with a liquid crystal display. Powered by finger batteries.

Pros:

- Measurements in the range 0-1.8 mm;

- Basic calibration;

- Compact, weight 64 grams;

- Fast preparation and measurement;

- Price.

Cons:

- According to customers, there are no special shortcomings.

ETARI ET-444

It is used for determination of the thickness of paint coatings on ferrous metals and steels with magnetic properties. It is popular when looking at a car to be purchased in order to identify the retouched body defects.

Advantages:

- Measurements in the range 0-2000 μm;

- Ambient temperature from -25 to 50 ° C;

- Russified menu;

- Easy to use;

- High measurement accuracy;

- Can be used for non-ferrous metals and alloys after additional adjustment.

Cons:

- Perhaps a little overpriced.

BIT-3003

Small size, made in the form of a marker, the tester will allow you to perform measurements of the coating and identify the previously produced bodywork.

Pros:

- Compact;

- "Unbreakable";

- Works in cold and hot weather;

- Price.

Cons:

- Low precision;

- Suitable only for ferrous metals;

- Price( subjective assessment).

ET-05( allsun em2271)

Tester for determining the thickness of applied coatings on ferrous and non-ferrous metals. It is simple in application. Convenient for determining the repainted parts of the body.

Advantages:

- Small dimensions;

- Weight 23 g;

- Easy to use;

- Speed.

Disadvantages:

- Works in test mode;

- Low measurement accuracy.

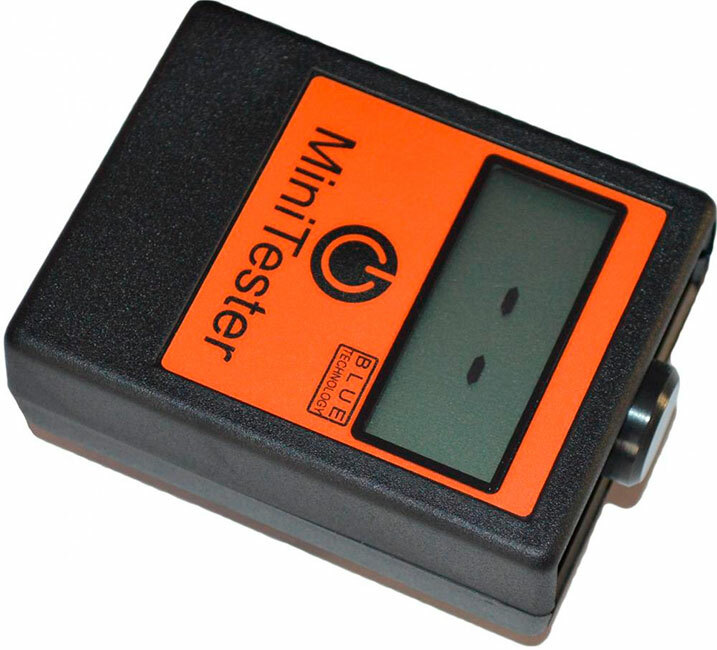

Mini A-10 Fe

Miniature thickness gauge for measuring the sizes of different coatings on a magnetic substrate. Used for preliminary inspection when inspecting the car body.

Advantages:

- High measurement accuracy;

- Speed of thickness determination( 0.3 seconds);

- Large display;

- Operation all year round;

- Ease of use.

Disadvantages:

- Price;

- Work only on black metals.

The best eddy current( electromagnetic) thickness gauges

ETARI LCP ET-110

The device is made in the form of a cell phone model. It is used by buyers, repairmen, appraisers, agents in the control of car coatings.

Pros:

- Measured coating thickness 0-1000 μm;

- Speed, no more than 1 sec.;

- Light weight;

- Convenient form;

- Russified menu;

- Year-round use.

Cons:

- Work only on black metals;

- No self-calibration.

Megeon 19080

The device determines the thickness of the coatings, polymer coatings on metal conductive surfaces. Has no damaging effects on the surface.

Advantages:

- Convenience, simplicity;

- High performance;

- Autocalibration;

- Measurement accuracy.

Disadvantages:

- Price;

- Necessity of zeroing previous results with continuous monitoring.

KEEPER LK PRO

Measures in continuous and single measurements. Designed for use in car centers, workshops, insurance and appraisal companies.

Pros:

- High measurement accuracy;

- Radius of rounding 1.5 mm;

- Auto Calibration;

- Memory for 320 parameters;

- Relationship with PC;

- Software.

Cons:

- Price( subjectively).

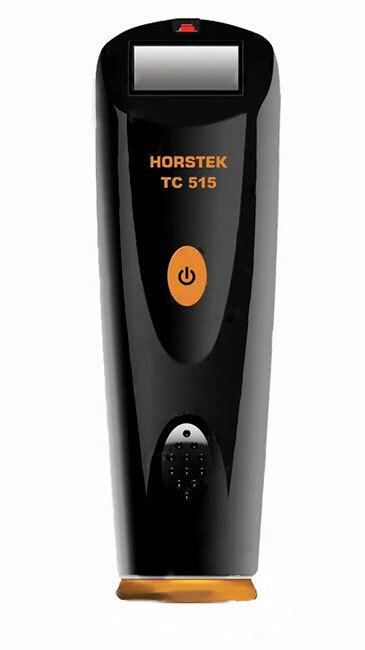

Horstek TC-515

Thickness gauge is used to measure coating applied to ferrous metals or aluminum. A high-speed device is in demand in auto repair shops, insurance agents, appraisers.

Advantages:

- High measurement accuracy;

- Speed is not more than 0.2 seconds;

- Ergonomic housing;

- Russified menu;

- Illumination of the display;

- Compact and lightweight( 50 grams);

- Simple operation.

Disadvantages:

- High enough price.

BT-201

The tool is used for measuring non-magnetic coatings on conductive materials, including aluminum, copper, titanium. Introduced to the State Register.

Advantages:

- Measurement accuracy;

- Wear-resistant probe tip;

- Operating mode for recharging up to 25 hours;

- Memory for 5000 measurements;

- Ability to program.

Disadvantages:

- Price;

- A fairly narrow specialization.

The best combined thickness gauges

CEM DT-156

Specialized device for determining the size of coatings from coatings, polymers applied to a metal or other surface. Used in the automotive industry, car service centers, trade companies offering used cars.

Pluses:

- Measurement on ferrous and non-ferrous metals;

- High accuracy;

- Minimum radius of 1.5 mm;

- Two modes: permanent, single;

- "Alarm size" function;

- Fast preparation;

- USB port.

Disadvantages:

- Price;

- Narrow specialization.

ETARI LKP ET-350

It is operated on magnetic( ferrous metals) and conductive surfaces( non-ferrous metals).Determination of the surface type in automatic mode with display. Setting the units of measure.

Strengths:

- Compact, lightweight;

- Ease of use;

- Several calibration steps;

- Extended configuration.

Weak:

- No self-calibration;

- Readings are floating at negative temperatures.

ADA ZCT 888 A00359

Semi-professional tool. Carries out measurements of coatings on ferrous metals and non-ferrous alloys. Used in garages, laboratories of aircraft and shipbuilding, chemical industry.

Advantages:

- High measurement accuracy;

- Memory for 2500 measurements;

- Continuous and single modes;

- Ability to calibrate;

- USB port;

- Two modes.

Disadvantages:

- No self-calibration;

- Price( subjectively).

Condtrol INFINITER InCO

The device for precise measurements of the thickness of coatings on metallic magnetic and conductive substrates. Designed for the automotive industry, laboratories involved in the control of finished products.

Pros:

- High measurement accuracy;

- Large display;

- Relationship with the computer;

- Memory for 320 parameters;

- Carrying case.

Cons:

- No significant user defects were noted.

Megéon 19125

Portable tool for quick measurement of the coating without damaging it. It is used for magnetic steels and non-ferrous metals. Equipped with a beep.

Advantages:

- Measurement accuracy;

- Single or group measurement;

- Minimum, average and maximum parameter;

- Output to zero;

- Calibration;

- USB port;

- Backlit screen.

Disadvantages:

- No self-calibration;

- Price( subjectively).

The best universal thickness gauges

Gradient TP-2000

Designed to take readings from all kinds of bases on coatings made of metal, conductive material or dielectric. The lining method is used. It is used in construction, road industry.

Strengths:

- Compact;

- Remote probe;

- Measurement accuracy;

- Ability to calibrate;

- Added to the State Register.

Weaknesses:

- Preliminary preparation is required;

- Training is needed.

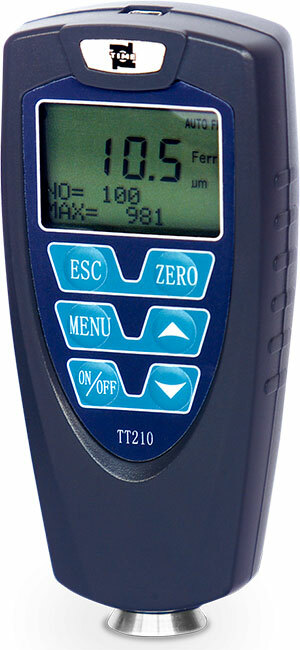

TT-210

Ultra-compact tool with an internal sensor that determines the thickness of the coating on a magnetic or conductive material. It is used in many branches of the economy, including scientific and technical laboratories.

Advantages:

- Material Recognition;

- Minimum, average, maximum value;

- Calculation of error;

- Memory for 500 parameters;

- Single and continuous modes;

- Communication with a computer.

Disadvantages:

- No negative values were detected by the device for consumers.

Constant МК4-ПД

Small-sized device for working with many types of coatings on metal and non-ferromagnetic materials. Used in the automotive and construction industries, laboratories to monitor the quality of protective coating.

Advantages:

- Matrix indicator;

- is included in the State Register;

- Battery or external power source;

- High economy on a single charge( & gt; 60,000 cycles);

- Warranty 3 years;

- Small size.

Disadvantages:

- Price( subjectively).

Elcometer 456 Top

A digital instrument with exchangeable monitoring sensors that allow measurements on many types of coatings, polymers, mastics applied to different types of substrates. It is used in various industries.

Strengths:

- Compact;

- Versatility;

- High accuracy;

- Ease of use;

- Color contrast display;

- Russified menu;

- Weatherproof enclosure.

Weak:

- Price( subjective assessment).

PosiTector 200

Used to determine the thickness of the coating for many types of substrate, including concrete, asphalt, wood and products of its processing, etc. It is used in construction, road construction, production of composite products.

Advantages:

- Immediately ready for action;

- Several layers are possible;

- The Russified menu;

- Ability to work with the device with one hand;

- Durable and resistant to various materials;

- Communication with a computer;

- Working with the printer;

- Software;

- Memory for 10000 readings;

- Backlit screen.

Disadvantages:

- Price.

The best mechanical thickness gauges

ZUBR EXPERT 34480-25

Mechanical tool for working with small parts with high accuracy of measurement. The end faces of the measuring probes are made flat with a high degree of smoothness.

Advantages:

- Simple application;

- Durable and reliable metal housing;

- High service life;

- Measurement accuracy;

- No backlash.

Weaknesses:

- Users do not note shortcomings.

FIT IT 19909

External device for removing parameters or controlling the factory size. It is made in the form of a clamp and a rotary-measuring mechanism.

Strengths:

- Price;

- Sturdy tool steel;

- Wear resistance of the probe surface.

Weak:

- No customers noted.

MATRIX 317255

Precision tool made of tool steel. Removes readings from parts with a thickness of up to 25 mm.

Pros:

- Measurement accuracy;

- No play;

- Workmanship.

Cons:

- No users are marked.

What thickness gauge to buy

The methods and objectives of the measurements are different. Hence, each consumer needs his own measuring device:

1. One-time purchase of a car. The purpose of the device is to reveal the brushed areas of the body repair. With its tasks the budget model Megeon 19200 or Mini A-10 Fe will cope.

2. It is planned to buy another car in the near future, then you should pay attention to the Megeon 19080 thickness gauge. This device can bring additional income when renting it.

3. Do you have a car repair workshop? Are you an insurance agent or an appraiser? Then, at your service, ETARI LCP ET-110, Horstek TC-110 or Condtrol INFINITER InCO.

4. You are engaged in engineering production. You constantly need to control the size of small parts. Micrometer ZUBR Expert 34480-25 will be, as it is impossible, by the way.

5. A serious tool for accurate measurements. For the industry, Megion 19125, Elcometer 456 Top or PosiTector 200 is useful.