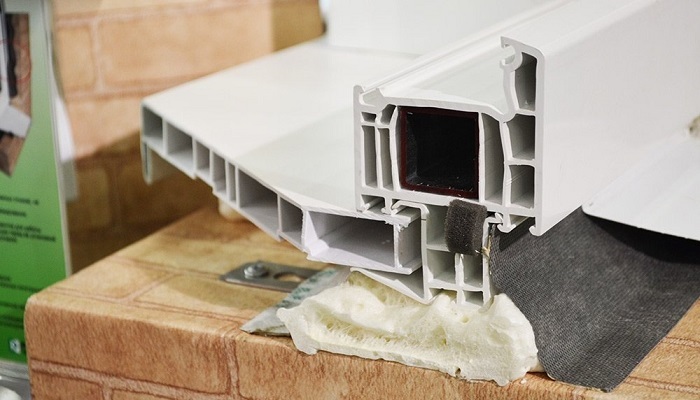

The technological element of the window structure, which is installed under the window sill and serves to support and fix it, is called the stand profile for PVC windows. The structural element is made of various materials such as wood, plastic or metal. Plastic window sills provide strong support to the window sill, preventing it from sagging or warping. The plate can also have a decorative function, adding aesthetic appeal to the window structure.

What is the purpose of the stand profile?

When installing windows in a house or apartment, one of the important elements is the striker for plastic windows. This is a special design that is installed under the window frame and performs several functions:

- The mount serves to creating a reliable support for the window frame. Lining plastic prevents sagging of the window sill and deformation under the influence of the weight of the double-glazed window and other window elements. Thanks to this, windows remain reliable and durable, without requiring regular repair or replacement.

- Substitute aluminum block ensures the tightness of the window structure. There are no gaps between the frame and the wall through which cold air or dust can penetrate. This significantly reduces heat loss in the room and creates comfortable living conditions.

- Profile for window sill PVC improves the sound insulation of windows. The tape prevents the penetration of noise from the outside, which is especially true for residential premises located in noisy areas or near roads. Thanks to this, a quiet and calm atmosphere is created inside the room, which has a positive effect on the quality of rest and sleep.

- Use advantage connecting lining profile - its aesthetic function. Plastic allows you to hide wall irregularities and other defects that may occur when installing windows. Due to this, window structures look more neat and attractive.

The installation profile for plastic windows is made of plastic, aluminum or wood. The choice of material depends on individual preferences and interior style. Profiles can have different colors and shades, which allows you to choose them for window frames and the overall design of the room.

Window frame protection during transport

When transporting window frames, it is necessary to ensure their reliable protection in order to avoid damage and maintain quality. This is especially important when transporting windows over long distances or in adverse weather conditions.

One of the most common ways to protect window frames is to use special packaging. It may include a film or bubble wrap that reliably protects frames from scratches, chips and other damage. The packaging must be strong enough to withstand external influences and prevent deformation of the frames.

Additionally, to protect window frames, you can use wooden or plastic corners, which are fixed at the corners of the frame. This prevents deformation and damage due to impacts or falls during transport, including window support profiles.

Ease of fixing the sill and window sill: convenience and aesthetics in one

Fastening the ebb and window sill is an important step in the process of installing window structures. Excellent fastening guarantees the reliability and durability of the structure, gives the windows an aesthetic appearance.

For ease of fastening the ebb and window sill, manufacturers offer various fastening systems. For example, these can be special clips or brackets that are easily and quickly fixed to the window frame. Such systems avoid the use of additional tools or complex installation work.

It is recommended to take into account the aesthetic component when fixing the ebb and the window sill. Many manufacturers offer a variety of finishes that allow you to choose the color and texture. ebb and window sill in such a way that the structural elements are in harmony with the interior premises.

Improved thermal insulation: energy savings and indoor comfort

One of the key points that you should pay attention to when choosing and installing windows is the thermal insulation of PVC joint profiles. High-quality thermal insulation of windows reduces heat and energy losses, which leads to savings on heating and increased comfort in the room.

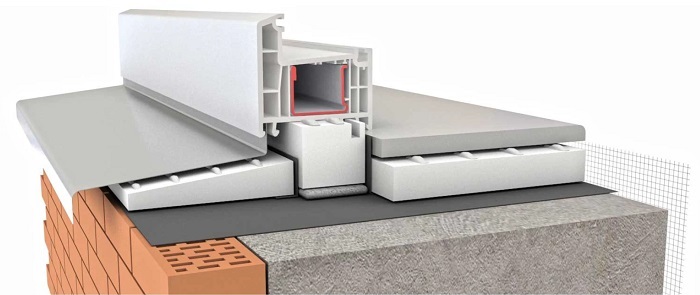

To improve the thermal insulation of windows, various technologies and materials are used. For example, multi-chamber profiles made of PVC or aluminum with a thermal break provide complete thermal insulation due to the presence of air chambers inside the profile. It is also important to pay attention to quality of double-glazed windows, which should have low thermal conductivity and good tightness.

Proper installation and durability of the window: a guarantee of reliability and durability of the structure

Proper window installation is an important factor for its durability and reliability. Incorrect installation can lead to problems such as freezing, drafts, condensation, and others.

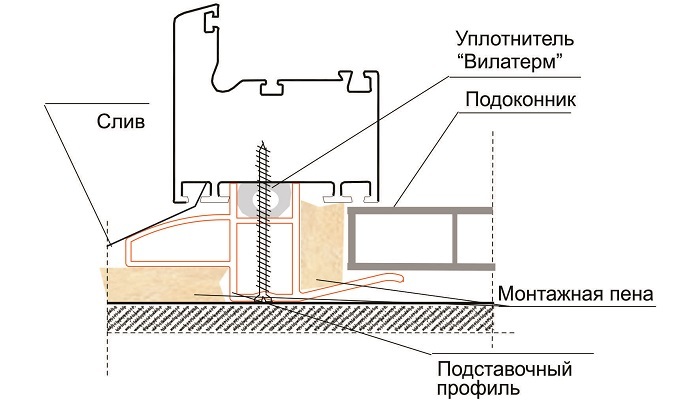

For the correct installation of the PVC window sill profile, it is necessary to pay attention to several working points.

- Properly prepare the opening under the window so that the design matches the dimensions of the frame and provides a secure fit.

- Pay attention to sealing the opening and joints between the frame and the wall. This option will avoid the penetration of cold air and condensate.

- To make windows last longerthey need to be properly cared for. Regular cleaning and maintenance will help to keep in good condition and extend the service life of the installation profile for plastic windows.

Protection of the window frame during transportation, ease of fixing the sill and window sill, improved thermal insulation and proper installation of the window are important points that should be taken into account when choosing and installation. These measures ensure reliability, durability and comfort when using windows.

Types of substitution profiles for windows

The reciprocal plate for plastic windows is an integral part of the window structure. Profiles are installed between the window frame and slopes, providing tightness and thermal insulation. Depending on the design and functional features, substitution profiles can be of various types.

Insulated substitute profiles

The PVC joint profile is a special design in which an additional layer of heat-insulating material is used, such as expanded polystyrene or mineral wool. Insulation of profiles significantly increases the thermal insulation of the window structure as a whole.

Advantages of insulated substitution profiles:

- improved thermal insulation; an additional layer of insulation reduces heat loss through window openings, which helps save energy and reduce heating costs;

- increased sound insulation; insulated profiles reduce the level of noise penetrating from the outside, which creates more comfortable living conditions;

- resistance to moisture and rotting - the insulation used in such profiles is resistant to moisture and does not rot, which prolongs the life of the window structure.

Hollow wildcard profiles

Aluminum hollow substitution pads are structures in which there is a cavity inside the profile that is not filled with heat-insulating material. Such profiles have certain advantages, but they also have some limitations.

Advantages of hollow substitution profiles:

- low cost - pads are cheaper than insulated pads, which makes them more affordable;

- ease of installation - profiles are easier and easier to mount, since they weigh less and do not require additional operations to install insulation.

Restrictions of hollow substitution profiles.

- Low thermal insulation. Since there is no additional layer of insulation, thermal insulation is less effective. This leads to an increase in heat loss through the windows.

- Weak soundproofing. Hollow linings do not have the same high degree of sound insulation as insulated counterparts. This is a major drawback for operation in noisy areas or close to highways.

Depending on the requirements for heat and sound insulation, as well as on financial possibilities, the choice between insulated and hollow substitution profiles is not always unambiguous. It is necessary to take into account all factors and consult with professionals in order to choose the most suitable option for your home or office.

Advantages of the insulated stand profile under the window

The insulated stand profile under the window has the following advantages;

- improved thermal insulation prevents the penetration of cold air and heat leakage through the window opening;

- protection against condensation prevents the formation of moisture on the window opening, which can lead to mold and mildew;

- improved sound insulation helps to reduce the penetration of noise from the outside into the room;

- increased strength and stability provide additional rigidity and stability to the window opening;

- Enhanced Appearance: Allows the shoe to be available in a variety of colors and finishes while creating an aesthetically pleasing window opening.

Sizes and manufacturers of the insulated base profile

The dimensions of the stand profile for windows vary depending on the type and dimensions of the structure. Dimensions are selected to provide optimal support and stability to the window structure and range from 20 to 50 mm in height and 30 to 100 mm in width.

Shoe manufacturers offering different models and sizes.

- Rehau is a German company specializing in the production of window and door systems;

- Winkhaus is a German manufacturer of window systems, which also offers stand profiles in different sizes;

- Veka is a German company specializing in the production of plastic profiles for windows;

- Aluplast is a German manufacturer of plastic window systems;

- Deceuninck is a Belgian company specializing in the production of window and door systems;

- Salamander is a German manufacturer of plastic window systems.

These are just some of the many manufacturers of window support profiles on the market. When choosing a profile, it is important to take into account not only its dimensions, but also the quality of the material, the reliability and strength of the structure, as well as compliance with safety requirements and standards.

Step-by-step procedure for installing profile strips for PVC windows

The algorithm for installing profile strips looks like this:

- Prepare slopes and openings for window installation. Make sure they are level, clean and free from obstructions.

- Check the dimensions of the window opening and make sure they match the dimensions of the window with the substitution profile.

- Install the window frame in the opening. Make sure it is properly positioned and evenly distributed around the opening.

- Secure the frame with the fasteners provided with the window. Make sure that they securely fix the frame in the opening.

- Check the tightness of the installed frame. Make sure there are no gaps or gaps between the frame and the opening.

- Install the double glazing in the window frame. It must fit exactly in size and be correctly oriented inside the frame.

- Fix the double-glazed window in the frame using special fasteners or glue.

- Install window hardware such as handles and locks. Make sure they function properly and are securely attached to the frame.

- Check if the window works by opening and closing it several times. Make sure it opens and closes easily and tightly.

- Close the gaps between the frame and the opening with sealant or special insulating tape. This will help prevent air and water intrusion.

- Clean the window from installation traces and conduct a final check of its performance.

- Enjoy the new substitution profile window and its benefits such as energy efficiency and soundproofing.

Conclusion

Using window replacement profiles is a smart and efficient solution that saves warmth, provides comfortable living or working conditions, and also improves sound insulation premises. uPVC window strikers are reliable and durable, making them an excellent choice for any type of building.