Adhesion is a combination of different materials with different compositions and structures, which provides their physical and chemical properties. Adhesion is Latin for "sticking". In the construction industry, the term, what is the adhesion of materials, is indicated more precisely - this is a characteristic of decorative and finishing coatings (paint, etc.), sealant or adhesive mixture to the density of fastening with the outer layer of the base.

Kinds

Adhesion in construction is a bond between different materials. Technology is classified into 3 main categories:

- Mechanical - connection through the adhesion of the materials used to the main surface. This technique is based on the introduction of mixtures into the structure of the outer layer or connection with rough products.

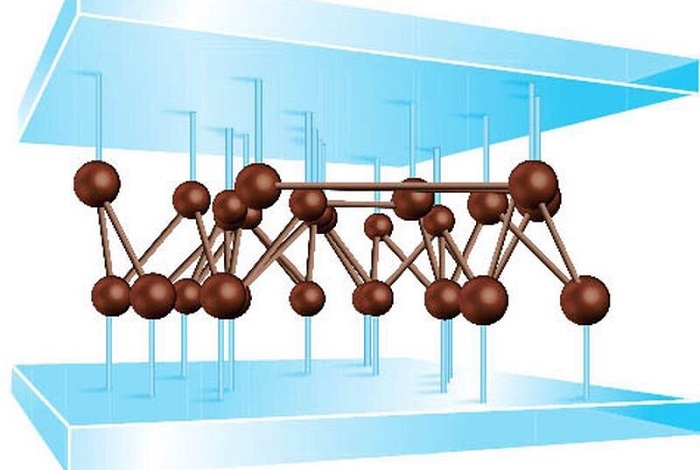

- Chemical — interaction of materials at the level of the crystal lattice (even at different densities). This interaction is provided by catalysts.

- Physical — an electromagnetic bond is formed between the connecting structures at the molecular level. Such a connection provides a static connection or a permanent magnetic or electromagnetic field.

Building and finishing materials with adhesion

The adhesion of building materials is provided mainly through mechanical and chemical bonds. In the construction industry, a huge number of products with different technical properties are used. The strength of adhesion to the main structure depends on this.

paintwork

Adhesion paintwork materials (LMB) with the base is carried out at the mechanical level. The necessary strength and reliability are provided when the main surface of the material is sufficiently rough or porous.

The adhesive properties of paints and varnishes are enhanced by a variety of modification additives:

- organosilane and polyorganosiloxane provide additional water-repellent and anti-corrosion characteristics;

- polyamide and polyester resin;

- an organometallic catalyst for hardening the outer coating;

- ballast fine filler (for example, talc).

Building plaster and dry adhesive mixture

Previously, various gypsum, lime and cement mixtures were used for construction and decoration. More often, these materials kneaded according to exact proportions, due to which the original technical characteristics were preserved as much as possible.

Various building components are added to the mixture:

- mineral - magnesia catalyst, liquid glass, aluminous, acid-resistant or non-shrink types of cement, microsilica, etc.

- polymeric - for example, a dispersible polymer (PVA, polyacrylate, vinyl acetate, etc.).

These additives significantly affect the composition of the mixtures and their technical characteristics, such as elasticity, water resistance or thixotropy.

Sealing mixtures

Sealing compounds, which are used in construction, are classified into three categories. Each type has certain conditions necessary for adhesive ability.

There are the following types of sealant:

- drying out. Polymer components and an organic solvent (butadiene-styrene or nitrile, chloroprene rubbers, etc.) are added to the mixture. Their viscosity is approximately 300-550 Pa.

- Non-drying. Their composition mainly includes rubber, bitumen and various plasticizers. Such sealants have poor resistance to heat and heat (up to 700-800˚С). With its increase, partial or complete deformation occurs.

- curing. When they are applied, irreversible polymerization occurs due to the influence of external factors (high humidity, temperature rise, chemicals, etc.).

adhesive change

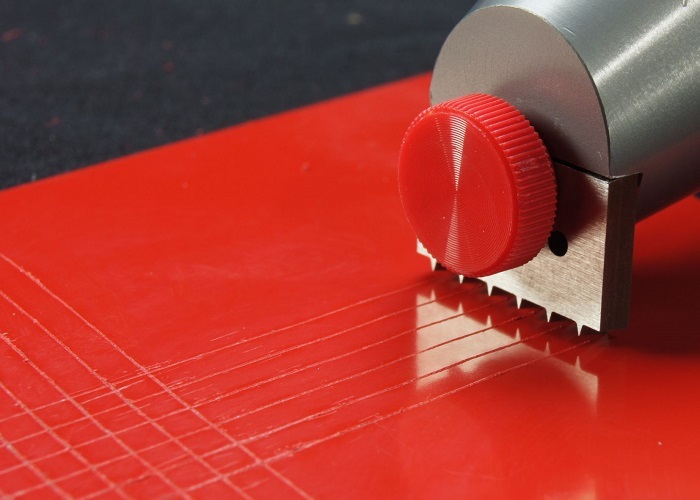

Adhesion strength is analyzed under the influence, in which the material is destroyed, loses its shape. Adhesion is also measured using ultrasonic devices:

- Adhesion knife. It is used to measure the characteristics of the adhesive layer through a lattice or continuous cut (deep but thin). The knife is used for paintwork and film coatings with a depth of not more than 200 microns.

- Pulsar 21. The equipment shows adhesive density. It is used to determine the deformation (crack, delamination of the structure) of the adhesion of concrete to concrete (including in a monolithic product). There are specialized firmware and technologies that can be used to determine the adhesion density with concrete products.

- SM-1U. Used to measure the adhesiveness of polymer and bituminous insulation using shifts (incomplete deformation of the material). The technology works on the occurrence of linear deformation of insulating materials. Basically, the method is used to measure the insulation strength of pipeline systems.

Reduced adhesion under the influence of external factors

Even high adhesion is affected by various physical and chemical factors. Physical effects include changes in temperature and humidity of the environment during the application of decorative and protective products.

Also, various contaminants affect the adhesive interaction, for example, dust on the surface of the outer layer. During operation, ultraviolet rays affect the strength of the paintwork fastening. Also shrinkage, tensile and compressive stress.

Chemical factors that reduce adhesive adhesion include various materials that contaminate work surfaces: gasoline and oil, grease, acidic and alkaline substances, etc.

Ways to increase adhesion

In the construction industry, many universal technologies are used to increase the adhesion of a decorative finishing coating to the main surface:

- Mechanical - the surface of the base becomes rough to increase the area of interaction. For this, processing with large abrasives is used, small pores are made, etc.

- Chemical - a chemical component (or compound) is added to the mixture of the finishing material used. Basically, polymer compositions are used that create strong bonds, which gives the materials high plasticity.

- Physico-chemical - a primer is applied to the main structure, which changes the operational chemical and physical characteristics of the product. For example, after processing, the resistance to high humidity in porous structures increases, the loose outer layer becomes denser, etc.

Ways to increase adhesion with different materials

The technology for increasing adhesive properties depends on the category of materials with which adhesion is required.

concrete structures

Concrete products are used in all types of construction. However, concrete has a fairly high density and smoothness of surfaces, which is why adhesion with other materials is one of the lowest.

To enhance the strength of fastening with finishing compositions, a number of characteristics should be taken into account:

- Dry or wet surfaces grounds. In general, the adhesive bond to dry surfaces is much stronger. However, various adhesive mixtures have been developed that require pre-wetting of the base surface. In this case, it is necessary to pay attention to the requirements of the manufacturer.

- Temperature external environment and the main surface. Almost all finishing materials are used for concrete surfaces at an ambient temperature of more than + 5 ° С... + 7 ° С. The concrete surface itself must not be frozen.

- Primer. It is mandatory. For dense concrete, a composition with quartz sand fillers (concrete contact) is suitable; for porous material (foam, aerated concrete), a deep penetration primer with acrylic dispersion is used.

- Modifiers. Ready dry plaster mixture already contains a variety of adhesive components. When the plaster is mixed on its own, other components are added to the mixture: PVA, acrylic primer, silicate adhesives, which give the finish moisture-proof characteristics.

Hardware

Of great importance for the strength of fastening paintwork materials with metal surfaces is the technology and quality of base preparation. When working independently, the following conditions must be met:

- Base degreasing - the metal is treated with a solvent (650, 646, R-4, white spirit, acetone or kerosene). If such materials are not available, gasoline can be used.

- Surface matting - the base is treated with abrasives of various grain sizes.

- Primer - use special paint-primers. Often they come with the main material.

Wood and wood composite

The wood has a porous surface with large irregularities, due to which the connection with finishing materials is quite strong and deep. However, additional preparation will make the adhesion more durable and resistant to external factors (compared to materials without pre-treatment).

When used together with acrylic paint, it improves properties such as:

- resistance to high temperature and humidity:

- protection against ultraviolet fading;

- biological protection of the material.

The wooden surface is treated with a primer with varying degrees of graininess. The composition of such materials necessarily contains nitrogen compounds and nitrocellulose.

Welding adhesion

Welding of metal products is one of the strongest and most durable ways of joining. Fastening does not require additional materials with which the surfaces are prepared for adhesion (glue, primer, etc.).

This process is based on the thermal activation of molecules. The outer layers of the bonded surfaces are heated to a melting temperature or more, due to which the connection of the molecules and the structures themselves is carried out.

Weld adhesion can deteriorate due to a number of factors:

- oxide films. They are removed mechanically or chemically before surface preparation. With strong heating, the oxide films decompose on their own, additional procedures are not required in such cases.

- Wrong selection chemical compositions of materials and electrodes. A significant role is played by the content of silicon and carbon in the composition of metal surfaces. For welding metals of different grades, electrodes with a minimum content of diffusive hydrogen are used.

- Insufficient melting depth metal. It is affected by the current strength and the speed of the electrode during welding.

Adhesion is one of the most important properties in construction and, in particular, when joining individual structures and surfaces. Because of this, various methods of enhancing adhesive properties are being developed. The use of special techniques guarantees a long service life of building structures and finishing materials, as well as savings in the choice of materials.