Everyone knows that the foundation is the foundation of the house. On a strong foundation, the house will stand for a long time and will not shake. But the foundations are different: both in design, and in size, and in the material used.

The vast majority of foundations are built of concrete - this has already been tested and reliable. But they are also different. The slab foundation is a solid reinforced concrete slab on which the house is then built. Columnar consists of several concrete pillars buried in the ground, on which columns are then installed. The tape runs along the perimeter of the entire building and under the internal load-bearing walls. The pile is a support for the superstructure of the main foundation.

Each type is selected for certain characteristics of the soil, the size and configuration of the building. What they have in common is that concrete work is carried out during their manufacture. And their technology is such that concrete is poured into a wooden form called "formwork". In fact, the manufacture of formwork is the second major operation in the construction of a house.

When building a small country house, it is quite possible and cost-effective to make a formwork for the foundation with your own hands.

Read in the article

- 1 Primary requirements

- 2 Formwork types

- 2.1 Removable options

- 2.2 Fixed varieties

- 3 What to consider when choosing a material

- 4 Formwork design calculation

- 5 Preparatory stage

- 6 How to make formwork for the foundation of the boards

- 6.1 What do you need to work

- 6.2 Step by step instructions for making

- 7 How to install shield formwork for the foundation

- 7.1 Tools and materials

- 7.2 Calculation and installation technology

- 7.2.1 Small shield option

- 7.2.2 Large shield modification

- 8 Installation of fixed formwork for the foundation

- 8.1 What is required for work

- 8.2 Installation technology

- 9 Conclusion

Primary requirements

The practice of construction work has developed basic requirements for formwork, which must be strictly observed. Only in this case it is possible to obtain high-quality formwork and, consequently, high-quality concrete casting - the foundation of the house.

The formwork is a three-dimensional form, which gives the solidifying liquid solution the necessary geometric parameters. In order to successfully fulfill its main function, the formwork must have high strength, which allows it to withstand the pressure of a liquid solution inside its boundaries without changing the given shape. It is necessary to be able to pour the solution in the presence of fittings. The assembly of formwork panels does not allow gaps between the formwork components of more than 0.2 cm. The assembled formwork must ensure the horizontality and verticality of the corresponding surfaces in the norms stipulated by the rules: a deviation of only 10 mm in height and 20 mm horizontally.

The first type of systems involves the complete dismantling of the structure after the concrete mixture has solidified. Therefore, when considering the question of how to properly place the formwork for the foundation, it is recommended to take into account that the connection of the system elements must be of high quality, but amenable to simple dismantling. Otherwise, the process of removing the structure may lead to damage to the base. Dismantling of the formwork is carried out only after the concrete has gained 50–65% strength.

Fixed formwork for the foundation is not dismantled after the mixture has solidified. Most often, such structures are used in private housing construction. They have a higher cost, but also advantages:

- serve as an additional heat and sound insulating material;

- strengthen the base;

- high-quality shields for foundation formwork protect against atmospheric and weather influences, mechanical loads.

Formwork types

Depending on the specific purpose of the formwork, there are two main types - removable and fixed.

Removable options

Formworks of the first type allow complete dismantling of the structure after the concrete mixture has solidified. When installing such formwork, it is necessary to carefully control all the connections of the elements and think over the technology of disassembly, which is carried out after the concrete has gained 65% of its standard strength.

For a removable option, you can rent prefabricated formwork in any configuration. For this purpose, a metal version is well suited - aluminum or steel.

Fixed varieties

Non-separable formwork remains in place forever. It plays the role of additional heat and sound insulation. The non-removable system partially strengthens the base. High-quality foundation formwork panels are an additional protection against atmospheric and weather influences.

Such functions are well performed by foam or expanded polystyrene shields. This material is resistant to atmospheric loads, has high thermal insulation characteristics and is environmentally friendly.

What to consider when choosing a material

Formwork can be made from various materials. With your own hands, it is easiest to make formwork from wood or foam. But foam materials are not very suitable for collapsible reusable formwork. In addition, there will be difficulties with the manufacture of all kinds of docking and locking devices.

For a fixed disposable (but eternal) formwork, in principle, any material is suitable. It is important that it provides all the strength requirements for the casting process, does not bend or break under the pressure of liquid concrete. It would be useful to estimate the cost of different materials to create the same design.

Formwork design calculation

Any serious work begins with the study of the issue and calculations. The calculation of the formwork will allow you to find out how much and what material will be required during the construction of the foundation. For example, consider the calculation of the wooden formwork of the strip foundation. During the calculation, you must do the following:

- determine the perimeter of the foundation sole and add to it the length of all load-bearing walls, the thickness and height of the tape base, based on the fact that the foundation is deepened;

- choose the cross section of the board, since the amount of material costs depends on this. It can be in three values - 100, 125, 150 mm, and the material costs depend on the choice of lumber thickness.

Having chosen the size of the board and knowing the area of the formwork walls, the cubic capacity of the boards necessary for the construction is easily considered. In addition to the edged board, you will need a bar, wire, spacer studs - their number is taken from reference books.

Preparatory stage

The preparatory stage begins with the development of a complete set of drawings for the entire formwork. One classic drawing in three projections is not enough here. It is necessary to present the entire formwork in the form of sections and make drawings for each section. A margin is added to the calculated length dimensions just in case.

Real work begins with digging a trench or foundation pit. The width also needs a margin, so it will be easier to assemble. Then this stock is covered with earth.

During installation, the formwork walls are reinforced with braces or supports, otherwise the liquid concrete will squeeze the walls out. If necessary, tightening studs are installed.

How to make formwork for the foundation of the boards

Formwork assembly technology has been worked out for a long time and tested on a huge number of construction sites. A person who knows how to work with wood is able to make parts and assemble the entire structure on his own.

What do you need to work

For work, you need to prepare tools and materials. You need a traditional carpentry tool: a hacksaw (or two are better - for longitudinal and transverse sawing), a planer, a hammer, nails in large quantities, a nail puller. Still need boards of the selected size. Their number is determined by calculation. You will need a bar for the cross ties of the boards, for supports and braces. And, of course, studs, at the rate of one for every 2-3 meters of wall length.

Step by step instructions for making

Formwork installation technology can be represented in the form of several steps:

- digging a trench or pit;

- preparation of formwork wall sections;

- assembly of formwork walls in a trench;

- strengthening the walls with struts and studs;

- a comprehensive check of the correctness of the assembly, the absence of gaps;

- checking the curing of concrete;

- demolition and cleaning of formwork.

When checking, all geometric dimensions, horizontal and vertical installation, and the absence of cracks are carefully checked.

How to install shield formwork for the foundation

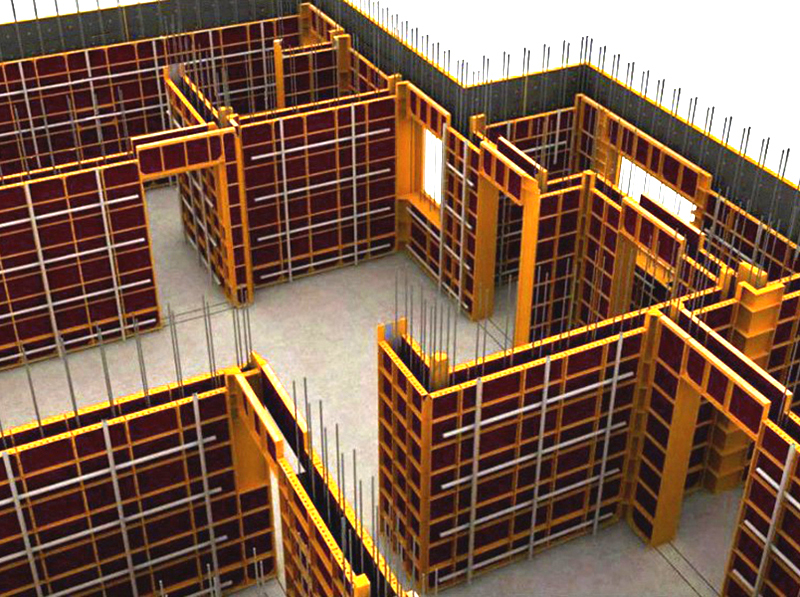

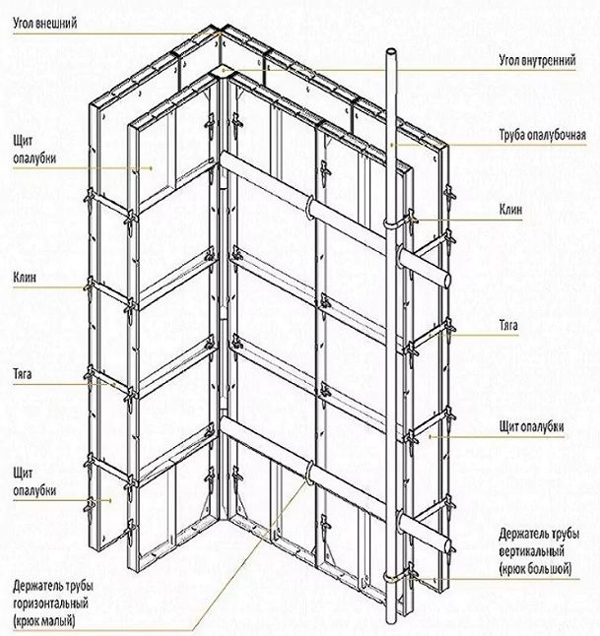

The need to increase labor productivity in the construction industry brings to life new efficient technologies. The method based on the use of panel formwork is based on the creation of a temporary form from panels of different sizes to obtain a concrete casting of complex configuration. The formwork is mounted in a frame not from boards, but from panels of different sizes. The panel formwork for the foundation and walls is a collapsible structure. It is dismantled into its component parts after the concrete has completely cured.

Tools and materials

Tools for working with panel formwork are required, mainly locksmith. You don't need to make anything again. Parts are taken from the warehouse in accordance with the technical documentation, and the desired design is assembled.

Calculation and installation technology

The calculation is subject to the determination of the quantity and nomenclature of the necessary parts. The installation technology can be called a screwdriver, nothing is required to be manufactured and completed. It is only necessary to assemble the structure in a standard way.

Small shield option

In this version, the frame and stiffeners are made of 5 mm thick sheet steel. The board deck is made of laminated plywood 15 mm thick. The width of the elements is in the range of 0.2–1.5 meters, the height is the same, the mass of individual elements is from 12 to 50 kg.

Large shield modification

The main advantage of the large-panel formwork modification is the ability to assemble a jointless formwork system and obtain high quality large free-form products. Even an entire room can be cast in one go. This method is used in the construction of walls, foundations of various shapes, ceilings (floors and ceilings), columns. Installation and dismantling are carried out very quickly, and the savings in time have a strong effect on reducing costs. Large-panel formwork has an important property of reusable use. It can be used dozens or even hundreds of times.

The sequence of installation work is as follows:

- the construction site is being prepared;

- reinforcing body is installed;

- shields are mounted on one side of the reinforcing body;

- shields are mounted on the other side;

- concrete is poured from the scaffold.

Formwork structural elements are lubricated with a special compound to reduce cement mortar adhesion to them. The work uses deep vibration installations. And be sure to involve lifting mechanisms.

Installation of fixed formwork for the foundation

Fixed formwork is often left on the foundation. This partially reduces labor costs, to some extent it is an element of thermal insulation. Sometimes unremoved parts that remain in sight are even decorated.

What is required for work

To perform such work, extruded polystyrene foam is required. It is produced in the form of foam boards. Eliminates the need to purchase expensive wood for traditional formwork, which is simply burned after completion of work. And you don't need to deal with stripping.

When mounting the formwork, the sheets are interconnected closely, without gaps. The connection is made with universal polymer ties and screws. Two operations are combined into one - the construction of the formwork and the thermal insulation of the foundation. This prevents troubles when heaving the soil in cold weather. As a result, the structure withstands the pressure of liquid concrete poured into the volume of the foundation without destruction.

Installation technology

Fixed formwork begins to be mounted from the corners. Holes are drilled along the edges of the foam boards and universal ties of the first row are mounted in them. They are secured with special locks. Then the lower horizontal layer is mounted. It is made from pieces cut to the desired size. In corner joints, all plates are connected to each other using polymer screw screws. For greater tightness, in order to prevent concrete leakage, the seams should be coated with polyurethane adhesive-foam and the sheets should be additionally fastened with nail plates.

The plates themselves have a stepped edge, which provides increased tightness of the joints. The blank of the structure is reinforced with a phased installation of screeds and clamps for reinforcement, iron rods are combined into one piece with a knitting wire.

Concrete is poured into the finished formwork and must be vibrated to remove air cavities.

Conclusion

Construction technologies based on concrete casting are increasingly becoming part of the practice of the construction industry. Concrete casting is impossible without formwork. Therefore, the development of technologies and designs of formwork types are of great importance for increasing the pace of construction.

With my own hands, I can't build very well. My wife and I decided to buy a bath from the tower ...

Partly, I liked the interior, I was impressed by the estate, I started to smile, only …

In my opinion, going to the village is too much, if there are no plans to take care of the household. Could…

It looks more like Lerchek bartered furniture, renovations, décor, and clothing. And there h...

When Buryatia was included in the Far Eastern Federal District, housing prices jumped more than 2 times due to this ...

It's a pity we don't have such a program as in the Far East. I had to buy a country ...

I've been looking at buying a sauna for a long time. I recently found exactly that one at an exhibition in Zyablikovo ...

A friend designed a garage for me. It remains only to find a team for implementation. Well on…

Guys, it's not complete. You do not mention Domorost, but still these guys have a problem ...

Hello, thank you for the informative information. Health to you and your loved ones. Sk…

From strong winds, fences sometimes fall if they are installed unreliably. We have our own at Terem-p ...

We bought a summer cottage with a dilapidated country house. They restored it through the tower. AND …

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?