What does it cost us to build a house? But a house, even the smallest one, is still taller than human height, not to mention 2 or 3-story ones. And in order to get to the highest point of the construction site and work there safely and comfortably, scaffolding is installed. They are placed around a house under construction or inside it, and several people can work on scaffolding at different heights at the same time. At large construction sites, industrial scaffolding is erected, and when building a summer house, you can use scaffolding made by yourself.

Read in the article

- 1 Varieties of designs

- 2 How to make your own wood scaffolding

- 2.1 Tools and materials

- 2.2 Drawings and dimensions

- 2.3 Frame manufacturing

- 2.4 Frame assembly

- 2.5 Floor laying

- 2.6 Installation of hatches and stairs

- 3 How to assemble metal scaffolding yourself

- 3.1 What do you need to work

- 3.2 Drawings and diagrams

- 3.3 Strut preparation

- 3.4 Manufacture of adapters

- 3.5 Frame assembly

- 3.6 Section installation

- 3.7 Flooring manufacturing

- 4 Conclusion

Varieties of designs

For each type of construction and each type of work, scaffolding of a certain design is needed. They must ensure the safety of workers, provide them with convenience for performing technological operations, have a place to accommodate the necessary building materials and tools, withstand significant cargo.

Previously, scaffolding was made only of wood, but gradually metal began to be used more and more often. Metal is stronger than wood, more durable in operation, allows more design variations. Elements are made from it - modules, from which scaffolding of the required size and configuration is then quickly assembled at the construction site. Arbitrary arrangement of modules allows you to assemble the best option for a particular object.

For metal scaffolding, there is a wide variety of lock structures that allow you to quickly and firmly connect the modules on the site. They can also be quickly dismantled and compactly stored in a warehouse until the next construction site. Scaffolding structural elements perform the functions of a fence and the functions of ladders for moving vertically.

The most widespread are wedge forests, which got their name from the method of fastening the elements. Clamps have the ability to arbitrarily change the shape of the mounting unit during installation. They serve buildings of non-standard form. At suspended scaffolding, sections do not rest on the ground; they can be moved along the building. The cups have a lock that allows for particularly precise positioning of the sections. With mechanical scaffolding jacks, you can change the height of the working platform.

How to make your own wood scaffolding

Not always work, even at low heights, can be performed using a ladder. And you can't do without forests.

Tools and materials

Before you start assembling tools and materials, you need to decide for yourself on several questions:

- What will the object look like - what are its dimensions, how many floors?

- What kind of work is to be done - build a house or paint a facade?

- What kind of work is enough of your own skill and money - for wooden scaffolding or metal?

If it is planned to build a country house with one or two floors, then it is quite possible to get by with wooden scaffolding. And it is easier to work with a tree, and there will be enough skill, and you won’t need much money.

For the construction of wooden scaffolding, the usual carpentry tool kit is enough: a saw for wood, a planer, a hammer, a nail puller, a drill, a screwdriver, pliers. The presence of power tools (power saws, electric drills, screwdrivers) will help speed up the work. Materials - boards 1-2 inches thick and 1-6 meters long. Fasteners - nails, screws.

Pre-treatment of the boards is minimal: remove dangerous burrs on the ribs so that splinters do not drive into the hands. Cut to length as needed. Selected boards should be checked for strength: put the board on two supports at a distance of about 2.5 m from one another and jump on it. If it doesn't break, then it's fine.

Works on the facades can be used goats with flooring. They can be rearranged along the house, but they are not adjustable in height.

Drawings and dimensions

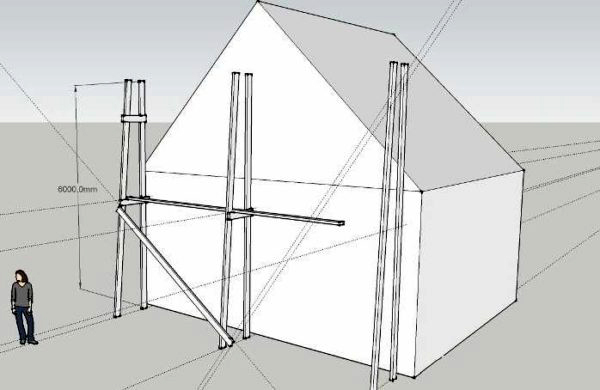

An approximate diagram with dimensions for scaffolding during the construction of a country house is shown in the figure below.

When building a country house, you can get by with scaffolding of varying degrees of complexity.

Attached scaffolds are not attached to the wall. They exist in two versions. Their configuration resembles the letter G, they are installed in different directions. They are not adjustable in height, but they are very easy to make and can be easily moved to a new place.

Frame structures are usually made of metal, but if the builder wants, then it can be made of wood. The set of frame scaffolding includes side frames, racks for diagonal and horizontal connection of frames to each other. Construction frame scaffolding is used in masonry and finishing works.

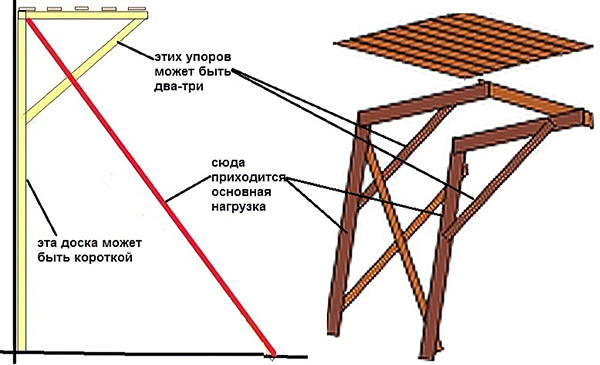

Frame manufacturing

The frame is made of boards 50–60 mm thick. Particular care should be taken to check the quality of vertical racks. Frames for country houses of 2-3 floors are unlikely to have standard, easily disassembled locks. The frame is assembled with nails. It is necessary to think over the design of the vertical frame docking unit. It is possible to mount nests at the top of each rack of the lower tier from short scraps of boards, where the lower parts of the racks of the upper tier will be inserted.

Frame assembly

Before starting the assembly of the scaffold frame, you should prepare a flat, smooth area and mark it out. On a house with a 6-meter facade, you can use three frames with a step of 3 m. Lay planks under the frames. In places of installation of vertical racks on beds, also mount mounting sockets. The frames of the lower tier are installed in these nests, they are set strictly vertically along the plumb line. The frames are interconnected with ties and attached to the wall of the building.

After that, you can install the frames of the second tier. They also need to be placed on a plumb line, fastened to the wall of the house and to each other. The third tier should be installed if the structure has grown higher than the scaffolding of the second tier. From diagonal deformation, each frame and the entire frame structure as a whole are protected by diagonal braces.

Floor laying

The deck is a work platform. Workers move along the flooring, tools and building materials are laid there. The flooring must withstand all this, so there are rules for its manufacture. Floor boards are manufactured in accordance with GOST 8486-86*. As a rule, from pine with a permissible bending stress [sc] = 150 kgf/cm2 .

Floorings are made of edged boards with a thickness of 25-40 mm. A thicker board is required when working with heavy objects. The flooring is formed in the form of an assembly of shields. The shield is assembled in a special way to prevent overturning moment. After the manufacture of the flooring, the entire structure undergoes a special strength test.

Installation of hatches and stairs

When installing the flooring, you should consider how the workers will climb to the tier they need. Ladders can be attached to end frames. Of course, you need to climb the stairs, holding on to the nearest upper rung with your hands. In the frame itself, a window should be provided through which a person will enter the working area of \u200b\u200bthe scaffolding, to his workplace. If necessary, you can make a window in the flooring. The hatch of the window should open upwards, and in the closed position should not reduce the degree of safety of the flooring.

Also, for the safety of workers on the 2nd tier and above, fences should be made at a height of about 1 m from the floor.

How to assemble metal scaffolding yourself

The creation of metal scaffolding requires the ability to work with metal and the knowledge of welding technology.

What do you need to work

First you need to decide on the type and size of future forests. Popular types are wedge and frame. There are others, but for a DIYer, the named ones are more convenient. Then it is worth deciding the issue with the choice of material. Most likely, it will be a profile or round pipe. Profile is more profitable and easier to work with. Its strength and rigidity is enough for such a product. Boards are required for flooring. You need a locksmith tool, and to work with the flooring you will need a saw, a drill and a screwdriver.

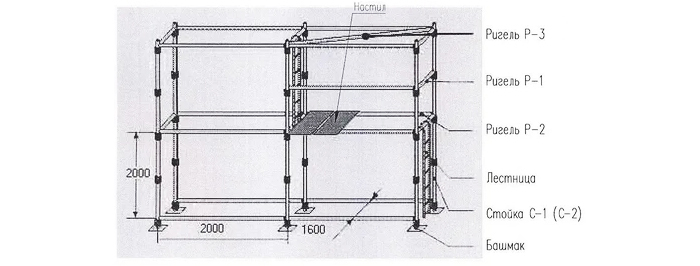

Drawings and diagrams

Any work on the creation of a product begins with its drawing. First, a general view is designed, then drawings of details are made.

Strut preparation

All parts must be made in accordance with the drawings. The work consists in cutting the pipes to size and, if necessary, installing locks on the machined ends. For diagonal struts, cut off 2 meters and for horizontal struts, cuts of 96 cm. On 2-meter blanks, cuts of 6-8 cm are made and the ends of the pipes are flattened.

Manufacture of adapters

Adapters are cut from pipes with a section of 25 x 25 mm 30 cm long, and from pipes with a section of 30 x 30 mm - pieces of 8 cm. The smaller piece is inserted into the larger one and boiled in the middle.

Frame assembly

The assembly of the frame begins with the assembly of the vertical ladder racks, after which the intermediate racks are assembled. Vertical racks are connected by side struts. Then horizontal supports are mounted, and a shield flooring is laid on them.

Section installation

The section appears when two frames are installed in parallel and connected with spacers. In this case, it is necessary to strictly monitor the verticality of the frames and their parallelism. The length of the spacers is determined by fitting. Assembly is done with bolts. The assembly of sections of the second and subsequent tiers is carried out in the same sequence of actions.

Flooring manufacturing

Flooring can be assembled in two ways. According to the first option, the boards are laid across, according to the second - along, parallel to the wall of the house.

In the first method, wooden flooring beams are screwed to the transverse pipes of the frame with self-tapping screws, and floorboards are attached to the beams. The transverse pipes are bolted to the frame.

In the second method, boards with a length of at least 2 meters are laid on the transverse elements of the frame. From below, the boards are fastened with bars so that they do not move apart and do not sag.

Conclusion

Scaffolding is a way of arranging the workspace at any construction site. They must ensure not only the safety of workers at any height, but also the convenience of access to tools and building materials. From a large number of varieties of structures, the construction manager must choose the most appropriate for the construction site and specific conditions. The right choice will lead to a good result.

From strong winds, fences sometimes fall if they are installed unreliably. We have our own at Terem-p ...

We bought a summer cottage with a dilapidated country house. They restored it through the tower. AND …

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?

Four days ago I ordered a Revolts heating kit for our dacha. I'm going to pick up tomorrow...

If the apartment is ready, then why doesn’t Buzova broadcast to the whole world about moving and living ...

Like 10m. Enough tape for 1.5m of fence?!

This is most likely an Internet modem like yota. And, I remember, they used both polarizers ...

Wicker fence is a waste of time and money. When we were equipping the site, we bought: up to ...

6 acres is a fairly small area, so there were no problems with zoning ...