Even a simple stool made of natural wood looks very beautiful, not to mention the unique furniture with carved decor. Of course, it is possible to make an exclusive product with a chic finish on your own, only if you have extensive experience working with wood and artistic talent, but anyone who knows how to handle a hacksaw and hammer. In today's material, HouseChief experts will tell you how you can make natural wood furniture with your own hands, having at your disposal several boards and a minimal set of tools.

Read in the article

- 1 Which breeds are suitable for making furniture for home and garden

- 2 Recommendations for choosing quality lumber

- 3 What tools will be needed for work

- 4 How to make a wooden hanger

- 4.1 Schema Design

- 4.2 Step-by-step instruction

- 4.3 Finishing

- 5 Making a wooden table

- 5.1 Drawing preparation

- 5.2 Production Guide

- 6 How to make a wooden stool

- 6.1 Schema Design

- 6.2 Step-by-step instruction

- 6.3 Final processing

- 7 Making a bedside table from wood

- 8 A few words at the end

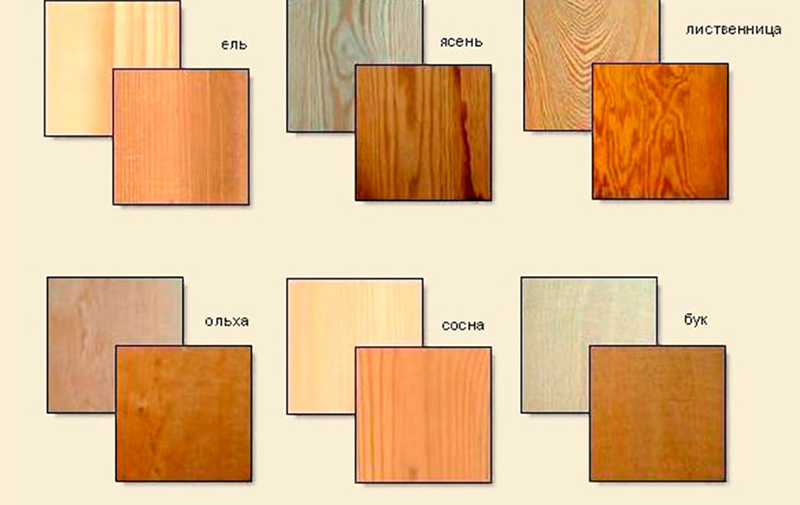

Which breeds are suitable for making furniture for home and garden

There are a huge number of wood species in the world, and each of them has different characteristics, a special color and a unique pattern. Some of them are suitable only for general construction work, others for the manufacture of furniture, and still others for the creation of decorative elements. Therefore, before making a hanger in the hallway or a table from solid wood, you need to familiarize yourself with the brief characteristics of the main types of wood.

Pine. The most popular and affordable type of wood, which has a beautiful color and texture. Pine lends itself well to processing, has antibacterial properties and smell. This lumber has a low density, so you should not use it for the manufacture of products subject to constant mechanical stress. Pine wood is best suited for the production of furniture facades.

Birch. It is one of the most environmentally friendly wood species with beautiful color and texture. The birch has a uniform structure and an average level of density, which ensures density and resistance to damage. Products from this material are recommended for use in children's rooms. Birch wood does not tolerate moisture and pests well, so it needs protective treatment.

Oak. One of the hardest wood species, which is widely used for making furniture. Differs in the high durability, durability, beautiful texture and well gives in to mechanical processing. Lumber perfectly tolerates moisture, temperature changes, is not affected by fungi and insect pests. The only drawback is the high cost of wood.

Ash. This type of wood is similar in quality to oak. Ash is durable, easy to process, resistant to mechanical stress. Due to its viscosity and flexibility, it is excellent for creating curved furniture elements. The wood is difficult to polish and requires a protective treatment against insect pests.

Beech. This type of wood is great for making furniture, because it has a beautiful color and texture, and is not inferior in strength to oak and ash. Beech wood is durable, easy to process and resistant to deformation. Its only drawback is poor resistance to moisture.

Nut. This is a wood with a beautiful texture, high strength and relatively low cost. It is very popular with craftsmen involved in the manufacture of exclusive furniture.

For a better understanding of which wood to choose for making furniture, you should familiarize yourself with this video.

Recommendations for choosing quality lumber

In order for the furniture to be strong and durable, you should choose high-quality lumber, adhering to some recommendations:

- the wood should be carefully examined for the absence of significant defects (cracks, chips, etc.);

- it is necessary to choose not too old wood;

- an array of natural wood should have normal humidity, since raw or overdried lumber is not suitable for making furniture;

- when using several types of wood, materials with a similar structure and characteristics should be chosen so that the shrinkage is the same;

- it is worth choosing lumber with parallel annual layers, otherwise it will crack during operation;

- attention must also be paid to the cut of the wood, because if it is very bright or has many spots, this is a sign that it is most likely infected with a fungus and is not suitable for making furniture.

What tools will be needed for work

In production and in private workshops, woodworking is carried out using various machines (sawing, milling, drilling, etc.). However, at home, for the manufacture of furniture, you can use a hand-held power tool, and preferably of high quality.

So, to make a table from a single piece of wood or any other piece of furniture with your own hands, you will definitely need:

- manual circular electric saw, electric jigsaw, wood saw;

- electric planer, grinder;

- electric milling cutter manual;

- electric drill and screwdriver;

- mechanical, electric or pneumatic furniture stapler;

- gas-burner;

- metal brush or a special nozzle for a drill;

- screwdriwer set;

- paints and varnishes and protective compositions;

- wood glue and PVA;

- paint roller and brushes;

- square, tape measure, ruler;

- clamps.

How to make a wooden hanger

There are a large number of different models of hangers for the hallway. These can be complex designs with a mirror and a cabinet for shoes, as well as simple ones, in the form of a small hanging shelf with hooks for clothes. The choice of design for self-production depends on the desire of the master and his experience with wood.

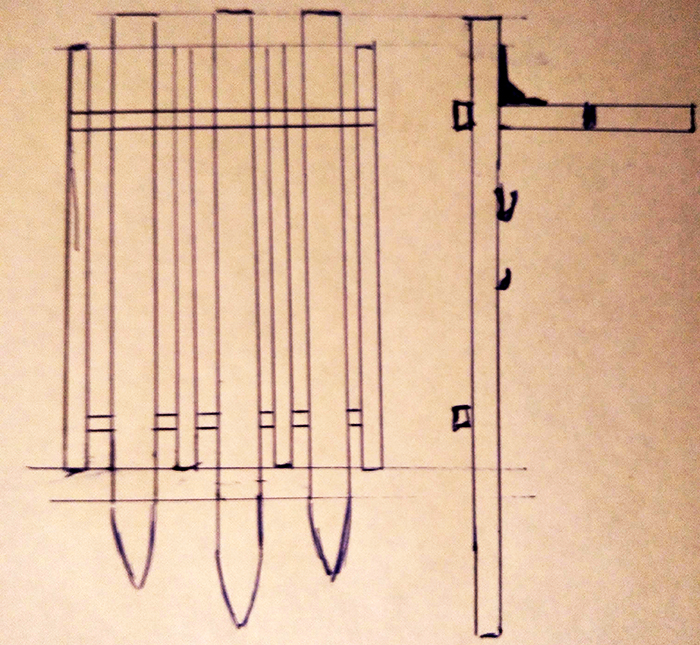

Schema Design

We offer a simple sketch of a wall hanger made of boards and timber. Dimensions are not indicated, but you can set any dimensions based on your own needs, as well as independently choose the thickness and width of the lumber. To make a homemade hanger, you can use boards from an old shipping pallet.

Step-by-step instruction

In accordance with the sketch and calculations, we prepare lumber, tools, fittings and fasteners. After you have collected the necessary, you can start making a wall hanger.

| Illustration | Process description |

| We mark boards and bars in accordance with the dimensions and detailing of our project |

| At one end of each board, we draw a contour that imitates the edge of a sword, and cut it out using a jigsaw |

| Carefully sanding boards and beams |

| We process all parts with a manual electric mill to get a rounded chamfer |

| We paint all the wooden parts of the hanger with stain, paint or colored varnish |

| We install brackets on the extreme side bars, to which we attach the parts of the shelf for hats |

| On the back of the future hanger, we attach two crossbars that will hold the entire structure together. |

| We fasten boards stylized as swords to the crossbars with the help of metal furniture corners and self-tapping screws, and the bars - only with screws. Vertical elements should be played among themselves, keeping a certain distance between them. |

| We mark the places of installation of furniture hooks for clothes and fix them with self-tapping screws. On the rear crossbars we install canopies for attaching the hanger to the wall |

| As a result, we get such a beautiful wall hanger |

Finishing

For finishing, you can use a special oil or stain, which will emphasize the beautiful texture of natural wood, paint or varnish. Brushing technology is also often used, with which you can achieve an antique effect, or firing followed by varnishing.

We suggest that you familiarize yourself with the video instruction for making another version of the original wall hanger made of natural wood, which you can easily make with your own hands.

Important! All elements of furniture structures made of natural wood must be carefully sanded. This will achieve a clear texture, smooth surface and eliminate splinters.

Making a wooden table

No home can be imagined without a table. It is necessary for cooking, studying, working, receiving guests, etc. Consider how you can make a durable and beautiful table of timber and slab with your own hands, which will successfully fit into the interior of a cottage or country house.

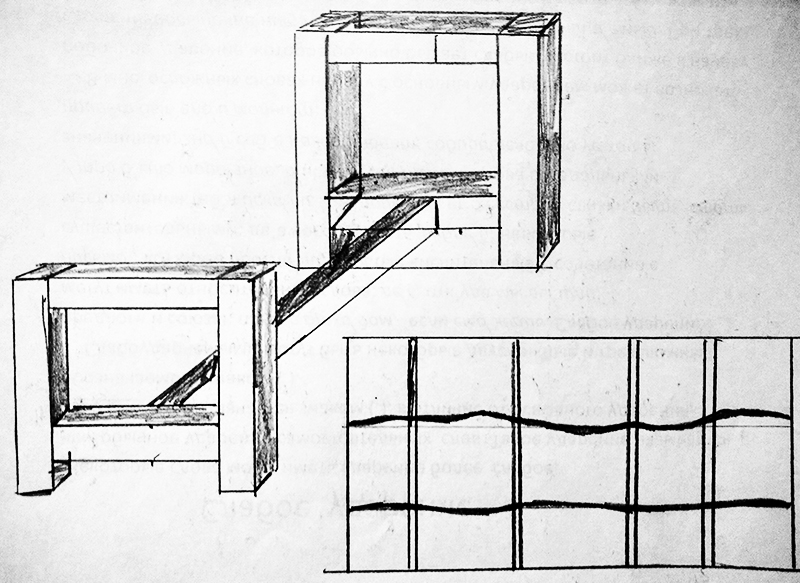

Drawing preparation

We offer a ready-made sketch of the table, and you will choose the dimensions yourself. For the manufacture of the structure, a beam with a section of 100 * 100, 30 * 50 or 50 * 50 mm and a board of 250–270 * 20–30 mm were used. It should be borne in mind that the height of a dining table with a table top should be on average 730–750 mm, and a width of at least 600 mm.

Production Guide

| Illustration | Process description |

| We mark and cut with an electric jigsaw or a hand-held circular electric saw timber, slats and boards according to the selected dimensions |

| On all parts, using a grinding nozzle on the angle grinder, we chamfer from all edges |

| Using glue and clamps, we assemble the frame supports of the table from the timber. We fix the parts together using screw anchors for wood |

| We connect the support frames to each other with a bar made of timber. Fixation is also carried out using wood anchors. |

| We apply curvilinear contours to the inner edges of the boards and cut them out |

| You should get such a blank tabletop |

| From the wrong side of the board we connect with each other with the help of transverse rails. A certain distance must be maintained between the boards |

| To facilitate the construction on the boards from the wrong side, we drill blind holes of small depth. If the thickness of the board is 30 mm, then a marker can be made on the drill by about 15 mm, which will greatly facilitate the task and will not allow drilling through the countertop |

| We cover the tabletop and other structural elements with two layers of colored varnish |

| As a result, we get a beautiful and reliable dining table for a country house, cottage or recreation area in the gazebo |

Watch a video on how to make a beautiful table that is suitable for home and garden.

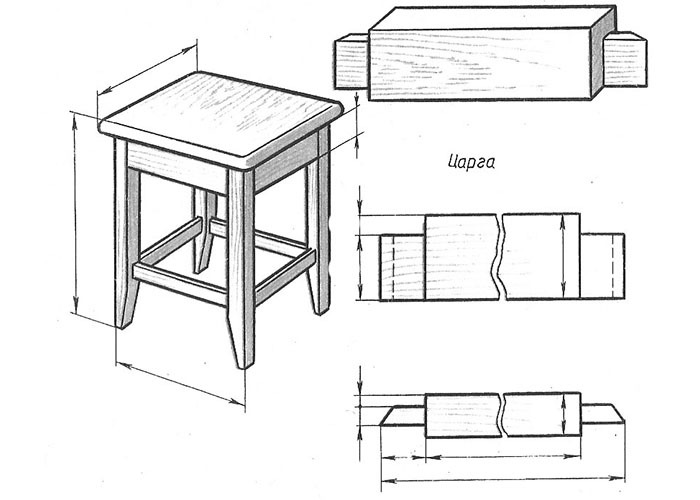

How to make a wooden stool

A stool, like a table, is the most popular and necessary piece of furniture. Consider step by step how to make do-it-yourself stools from old transport pallets.

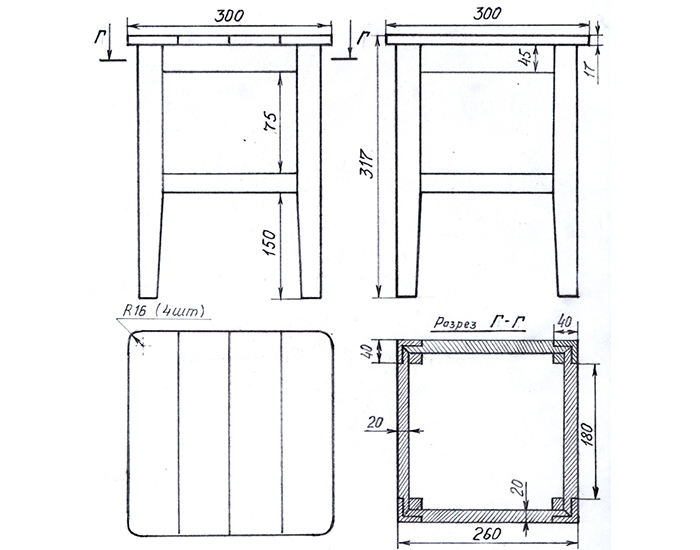

Schema Design

To make a stool, you can develop your own drawing or use a ready-made project from the Internet.

Step-by-step instruction

| Illustration | Process description |

| Prepare and cut boards, beams and rails in size and in the required quantity in accordance with the drawing |

| Using a hand mill or a hacksaw, a chisel and a hammer, make a spike to connect the groove / spike on the drawers and prolegs, and drill the corresponding grooves in the legs |

| From boards with glue and clamps, assemble furniture panels for further creation of stool seats |

| Assemble two support frames from legs, prolegs and tsargs. Glue the joints with PVA and tighten with clamps |

| Fasten the finished support frames together with drawers and prolegs |

| Fixation is also performed using PVA and clamps. |

| It turns out such stool frames |

| Cut the furniture panels to size and install on the frames. Play the overhang of the seat and fix it. Fixation can be done using furniture corners, dowels or self-tapping screws. Places of through fixation can be masked with wood putty or wooden plugs |

Final processing

Most often, natural wood stools were stained, but recently brushing and firing technology has become very popular.

Making a bedside table from wood

These two videos show the complete process of making a natural wood bedside table. This is such a detailed and understandable instruction that even a beginner can make this piece of furniture, provided that there is a desire and minimal skills in working with the tool.

A few words at the end

Handmade natural wood furniture is an opportunity to get unique furnishings. Having a great desire and following the instructions given in this article, you can easily make a table, stool or hallway hanger for your home. We hope that the information provided by our experts was useful to you.

Those who usually suck at life really do not understand a lot of things. And in general they regretted ...

That blogging shit again... Suck on!!!

I just can’t understand: where do juvenile cockerels and swallowers get such incomes from? Who encourage...

Basements in cities and private houses should not be built, they are often drowned. Regarding similar...

There was an idea to buy a country house with a carport. We found an interesting place near the…

We have been wanting to buy a painting on canvas for a long time and recently we were pleased with this by the company Va…

Didn't like the renovation. The kitchen is narrow, it was necessary to visually solve this particular pr…

unlike the palaces of our president's friends, this is just a miserable hut, albeit in style ...

Hello, my name is Andrey. I am buying information sites. There is…

and if the top layer of foam is not broken, then the lacquer surface greatly reduces the hygroscopic ...

strange reasoning regarding sealing. If the log is doused with sealant, foam ...

In the 80s he worked in one NPO, then hammer enamel was sintered. It turned out great,...

While in the summer I lived in the country a lot of different situations I saw and no one fines anyone. Uch…

You won't find a normal apartment for such a sum in Moscow. Even for a country house that …

Thanks. Briefly and clearly...