Most often, interfloor stairs in private homes are made of concrete. Such designs are characterized by increased strength and long service life, but the material is cold and unattractive in appearance. To correct this kind of shortcomings, concrete stairs are faced with tiles or natural wood. However, this type of finishing work has many nuances, without knowledge of which it is almost impossible to perform high-quality cladding. Homius experts in this article will tell you what is the finishing of a concrete staircase with wood and why this option is better than others.

Read in the article

- 1 Concrete stairs

- 1.1 Elements

- 1.2 Operating characteristics

- 2 Features of wooden cladding concrete stairs

- 3 Material selection

- 4 Methods for facing a concrete staircase with wood

- 5 Finishing a concrete staircase using plywood

- 5.1 Materials and tools

- 5.2 General preparations

- 5.2.1 Foundation preparation

- 5.2.2 Step Correction

- 5.3 Installation of blanks from plywood sheets on treads

- 5.4 Complete veneering of concrete surfaces

- 5.5 Cladding with wood details

- 5.6 Railing installation

- 6 Simplified options for installing wooden cladding

- 6.1 Installation on metal fasteners and glue

- 6.2 Installation with chemical anchors

- 7 A few words at the end

Concrete stairs

Concrete stairs, despite their heavy weight and unpresentable appearance, are in demand for several good reasons. Concrete, with the right composition and the observance of the pouring technology, has high performance characteristics:

- the material is not exposed to moisture, therefore, there is no corrosion;

- perfectly tolerates high mechanical and thermal loads;

- does not collapse from exposure to a chemically active environment;

- has a long service life.

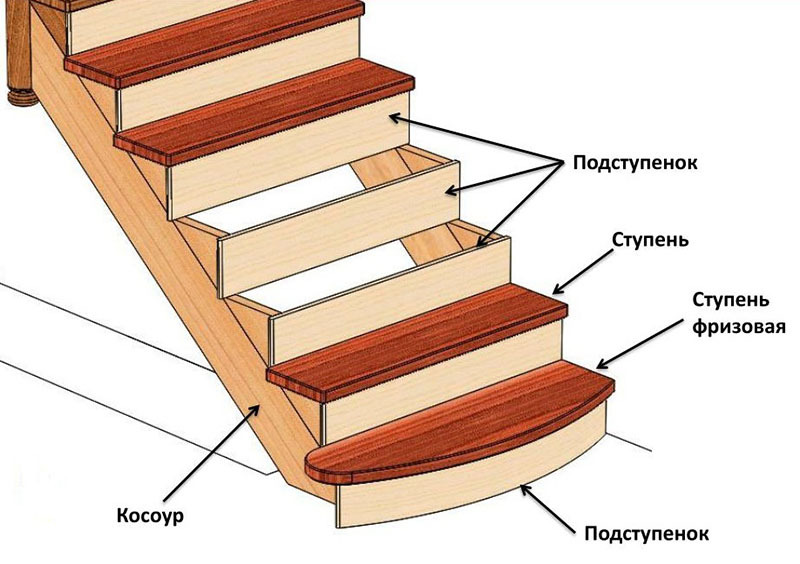

Elements

Before proceeding with the sheathing of a concrete structure with natural wood, you must first study its structure and terminology. Any staircase, as a rule, consists of the following elements:

- March (flight of stairs). An integral section of steps, which begins and ends with the platform. Depending on the project, there may be one or more flights of stairs.

- Tread. The horizontal plane of the step, which takes on the entire load.

- Riser. The vertical part of the step, which increases the bearing load.

- Railing. Low (up to 1 m) fencing of the flight of stairs and landings.

- Baluster. This is a vertical column, which is the basis of the railing.

- Handrail. The upper element of the railing, designed to support during the descent / ascent. It can be mounted directly on the wall if the fence is not provided by the project.

- Filing. Facing the stairs from the wrong side. You can even use not very durable materials, since the filing does not take on the load and performs a purely decorative function.

Operating characteristics

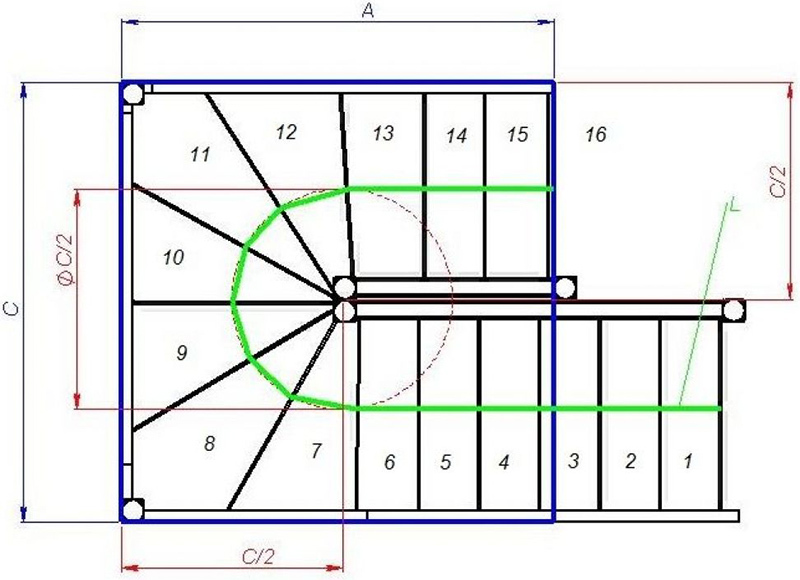

In addition to terminology, you should know and take into account some operational characteristics. And it is necessary to do this even at the stage of designing the structure, taking into account the intended finish, since changing the dimensions of the flight of stairs after its installation is quite problematic. The following important points must be taken into account:

- useful march width is the distance between two handrails or between a wall and a handrail. Measurements are taken at the level of the handrail, not the step;

- winder - a kind of step on the turn of a flight of stairs or landings. The tread is smaller at the pivot point;

- travel line - a conditional line along which a person moves, leaning on the main handrail. It is located at a distance of 30-50 cm from the handrail.

Features of wooden cladding concrete stairs

Sheathing a concrete staircase with natural wood is a great way to give even the most nondescript design a beautiful and presentable appearance. Such a finish will increase the level of comfort, but it has some features. There are only two ways of laying wooden cladding on the concrete base of flights of stairs and landings:

- on the logs

- on plywood.

Both of these methods are expensive and labor intensive. And, regardless of the option chosen, it is necessary to comply with some requirements for the material, and the order of finishing work:

- for facing steps it is necessary to use very durable wood, since they are subject to high mechanical stress;

- in order for the material to meet the requirements of operation, its thickness must be at least 30 mm;

- cladding of steps should be carried out last, after all finishing work on the upper floors has been completed, in order to exclude premature loading of the stairs.

Finishing concrete stairs with natural wood is only suitable for structures located inside the building, because under the influence of negative external atmospheric influences, this natural material will quickly begin to collapse. Wood cladding does not weigh down the structure and, with proper processing, lasts a very long time. Wooden lamellas are easy to install and have high maintainability. Since natural wood is an expensive material, experts suggest using MDF panels, moisture-resistant plywood or laminate as an alternative.

Material selection

Before sheathing a concrete staircase with natural wood, you need to study the main characteristics and properties of each of the species that is supposed to be used in the decoration. It is not recommended to save on the material, since the appearance, strength and durability of the cladding depend on its quality. The following types of wood are suitable for cladding stairs:

- Larch. Hard, durable, non-corrosive material. This applies only to wood that has been stored in a warehouse for a long time, since this species acquires its high characteristics over the years. Fresh lumber is unsuitable for facing work. Larch has a beautiful texture and a large selection of textures.

- Oak. Strong, durable and noble breed of wood. It is not subject to rotting, differs in moisture resistance, has a pleasant texture and color. All this makes oak a sought-after and at the same time expensive finishing material.

- Beech. Durable wood with a uniform beautiful texture. In the steamed state, it is flexible, which greatly facilitates many technological processes. Beech is not inferior in strength to oak, but it is cheaper.

- Ash. This breed has excellent hardness and viscosity, rich texture, does not rot. Relatively inexpensive, but difficult to process.

- Maple. Difficult to process, but very durable wood, which, after laying, is characterized by high stability and a long service life. Maple products can cost more than oak counterparts.

- Pine. In terms of cost, it is the most affordable and easy-to-process material. However, the low cost is due to the fact that pine is short-lived, not strong enough, and dents and cracks easily appear on it during operation.

Important! In pursuit of beauty, you need to be careful about exotic rocks, since some of them are not suitable for finishing staircases in their characteristics.

Methods for facing a concrete staircase with wood

Regardless of the choice of material for facing a concrete staircase, its attachment to the base of the structure must be as reliable as possible. The method of installation of steps and risers largely depends on the design and the chosen technology. Wooden cladding elements can be joined together butt-to-butt or with a slight overlap of tread over the riser. The parts are fastened alternately or an assembled section of wood is installed on a concrete base. Stairs can be lined with lumber completely. This will give the impression that it is entirely made of natural wood or partially sheathed (tread, wrong side, sidewalls, etc.).

Whatever method of cladding is chosen, it is necessary first of all to take measurements, prepare concrete surface and constantly check horizontals and verticals using a construction bubble level.

Finishing a concrete staircase using plywood

Sheathing a concrete staircase with natural wood using moisture-resistant plywood as an additional layer is the best finishing option. This, of course, makes the cladding process more expensive and increases the number of operations, but wooden steps will be mounted on an almost perfectly flat surface. In addition, plywood will perform a heat and waterproofing function, and the wood will not have direct contact with concrete.

Materials and tools

No business begins without careful preparation. For facing a concrete staircase with wood, you need to prepare the following materials and tools:

- perforator;

- electric drill and screwdriver;

- hacksaw or jigsaw;

- Sander;

- milling machine;

- hammer;

- bubble building level and plumb;

- roulette;

- construction square;

- drills for wood and concrete;

- facing material;

- plywood;

- cement-sand mixture for leveling;

- glue;

- dowels with screws;

- paint or varnish.

General preparations

Sheathing a concrete staircase with natural wood involves three mandatory steps: preparation of the base, veneering and finishing work. The main preparatory work includes the elimination of defects and the correction of degrees.

Foundation preparation

For high-quality sheathing of stairs with natural wood, it is necessary to first eliminate all existing defects in the concrete base. The surface must be free of cracks and bumps. After removing irregularities and before sealing holes and cracks, remove dust and apply two coats of primer to improve adhesion. When the last primer layer is completely dry, a putty or cement-sand mortar is applied to the concrete surface.

Step Correction

Often the steps of concrete stairs differ from each other in size. In case of strong deviations, it is necessary to correct them with self-leveling compounds. To fill the steps, you must first set the formwork. Often, tile adhesive is used to correct steps, which should be thicker in consistency than a mortar for laying ceramics or porcelain stoneware.

Correction should begin with the markup, which is applied to the wall adjacent to the flight of stairs or flight. The surface of the steps must be strictly in a horizontal plane.

After marking, beacons are installed, for which self-tapping screws are used, which are placed around the perimeter of the treads and leveled using a building bubble level. Lighthouses are designed to facilitate the leveling of the solution and create a perfectly flat surface.

Installation of blanks from plywood sheets on treads

The next stage of preparatory work is veneer. From moisture-resistant plywood, blanks are cut that correspond in size to the steps being trimmed. Further, everything depends on the chosen veneer technology. You can sheathe only treads with plywood or completely veneer the stairs. The first option is cheaper, but there is a possibility of condensation, which will affect the durability of the finish. In the second option, the consumption of materials increases, but greater rigidity, strength and durability are achieved.

Plywood blanks are laid on a concrete surface, the horizontal is checked, and holes for fasteners are drilled. Fixation is carried out using not only self-tapping screws and anchors, but also an adhesive solution, which will provide reliable fastening and additional waterproofing.

Complete veneering of concrete surfaces

With full veneering of the concrete surfaces of the stairs, the algorithm of actions will differ from the partial cladding of the structure. First of all, the panels for risers are fastened with anchors or dowels, after which a strip of tread is installed. To facilitate the work, you can pre-assemble each step separately, using self-tapping screws for fastening. Installation of plywood panels is carried out from the first, lowest step.

Cladding with wood details

After installing the plywood substrate, false bowstrings and drying the adhesive composition, you can proceed to the direct finishing of the staircase structure with natural wood. Facing with prefabricated elements is not difficult, since grooves for risers and holes for fasteners are cut into the material. In the case of working with home-made parts, you need to drill the appropriate holes and grooves in them with a milling machine and a drill.

The risers are attached first, fixing on the bottom of the panel with self-tapping screws. Next, liquid nails or polyurethane foam glue are applied to the plywood substrate, and sometimes both. Next, a wooden tread is laid, the groove of which is aligned with the riser and fixed with screws or anchors on a concrete base. It is not recommended to immediately tighten the fasteners to the stop, it is best to do this after the entire structure has been assembled.

In the event that the concrete base of the stairs is completely sheathed with plywood, the wooden cladding can only be fixed with assembly adhesive. For a snug fit of the skin, a load is placed on the tread (buckets of water, bags of sand or cement, etc.). The glued elements must dry for at least 24 hours.

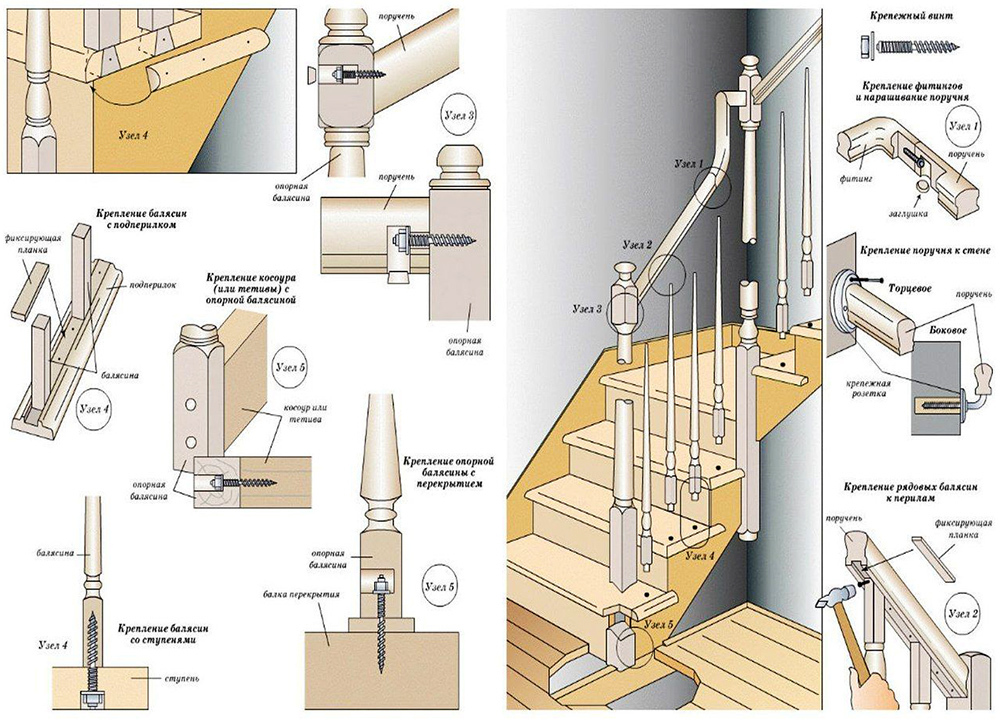

Railing installation

In the process of finishing the concrete structure with natural wood, the installation of stair railings is carried out at the same time. Installation technology depends on the type of fence. All parts are usually fixed with self-tapping screws. To mask the hats, use special plugs or putty with staining in the desired color. After installing the railing, the entire staircase structure is covered with two or more layers of tinted or colorless varnish.

Simplified options for installing wooden cladding

Veneering a concrete staircase before finishing with natural wood is the best option, but there are easier, cheaper, and less time-consuming ways. They are inferior to classical technology, but sometimes you have to resort to them.

Installation on metal fasteners and glue

Facing the stairs with a tree in this way is performed according to the following algorithm:

- The concrete surface of the steps is leveled.

- The top tread is installed and fixed.

- The riser is installed and wedged all the way along the line of contact. The horizontality and perpendicularity of the parts are checked.

- The remaining steps are also laid with careful marking of all elements and fastener points. Often, metal corners are used for fixation, which are subsequently closed with a riser and tread.

- The risers and treads are assembled into a single structure using self-tapping screws.

- The adhesive composition or mounting foam is applied to the concrete surface of the stairs and installed wooden structure with checking of horizontal and vertical surfaces using a building level.

- The wooden structure is fixed with corners and the riser is fixed with plastic dowels with self-tapping screws.

- All steps are lined in the same way.

Installation with chemical anchors

To fix the wooden sheathing on the concrete stairs, chemical anchors can also be used, which are two-component adhesives that fill holes drilled in the base designs. Fasteners are installed in the channel drilled in concrete, the adhesive solution fills all the voids and hardens, providing reliable fixation.

This option is used where steps made of plywood are not used and the installation of risers is not provided. The entire installation comes down to careful marking, drilling holes and fixing the steps.

A few words at the end

Often, cladding a concrete staircase with wood is a must. But when choosing a material, it should be borne in mind that it must fit into the overall style of the interior. We hope that the information provided by us will help you when finishing the concrete stairs in your home. If you have your own ideas and suggestions, please share them with us and other readers.

Those who usually suck at life really do not understand a lot of things. And in general they regretted ...

That blogging shit again... Suck on!!!

I just can’t understand: where do juvenile cockerels and swallowers get such incomes from? Who encourage...

Basements in cities and private houses should not be built, they are often drowned. Regarding similar...

There was an idea to buy a country house with a carport. We found an interesting place near the…

We have been wanting to buy a painting on canvas for a long time and recently we were pleased with this by the company Va…

Didn't like the renovation. The kitchen is narrow, it was necessary to visually solve this particular pr …

unlike the palaces of our president's friends, this is just a miserable hut, albeit in style ...

Hello, my name is Andrey. I am buying information sites. There is…

and if the top layer of foam is not broken, then the lacquer surface greatly reduces the hygroscopic ...

strange reasoning regarding sealing. If the log is doused with sealant, foam ...

In the 80s he worked in one NPO, then hammer enamel was sintered. It turned out great,...

While in the summer I lived in the country a lot of different situations I saw and no one fines anyone. Uch…

You won't find a normal apartment for such a sum in Moscow. Even for a country house that …

Thanks. Briefly and clearly...