Wood, stone, concrete and brick are the main materials from which front and interfloor stairs have always been made. They are solid, reliable, can be very beautiful, but have a lot of weight, which is not always convenient, especially when it comes to structures in private houses and duplex apartments. And the use of metal frames made it possible to create strong, reliable and fairly light stairs of almost any configuration. Most often, a metal profile is used for their manufacture. HouseChief experts in this article will tell you that a ladder made of a profile pipe with your own hands is it is quite realistic if you know about its varieties and nuances of manufacturing, as well as perform the correct calculations.

Read in the article

- 1 Features of a ladder from a profile pipe

- 2 Types of stairs from a profile pipe

- 2.1 marching stairs

- 2.2 Spiral staircase

- 2.3 stepladder

- 2.4 Ladder

- 3 How to calculate the parameters of a ladder from a profile pipe

- 4 How to choose a professional pipe for stairs

- 5 Do-it-yourself staircase installation

- 5.1 Materials and tools

- 5.2 Drawings and diagrams

- 5.3 Preparatory work

- 5.4 Ladder assembly

- 5.5 Construction painting

- 5.6 Installation of steps

- 5.7 Installation of fences

- 6 How to decorate the space under the stairs

- 7 Photo options of finished structures

Features of a ladder from a profile pipe

Usually, not the entire staircase is made from a metal profile, but only its frame. This is due to the fact that the all-metal construction will be very heavy and not always appropriate. Therefore, when creating stairs, a profile pipe is used in combination with other materials.

The features of metal stairs, which, in fact, are advantages, include the following:

- visual lightness of the design;

- reliability and long service life, subject to correctly performed calculations and assembly;

- relatively low cost for self-assembly;

- fast installation;

- good performance;

- the possibility of manufacturing a structure of almost any configuration;

- excellent compatibility with other materials, which allows you to make a staircase that can fit into any interior design.

Types of stairs from a profile pipe

A ladder on a metal frame made of a profile pipe can have almost any design. It can be located both outside the building and indoors, be stationary and mobile. However, despite the differences, all metal profile stairs have steps and support systems (kosour or bowstring). As a rule, a supporting beam is a support for a structure made of a profile pipe.

The main support system for stairs is of two types:

- Rectilinear kosour. In this case, a load-bearing beam with vertical supports is installed along the entire length of the flight of stairs, on which steps are attached.

- Broken kosour. The system consists of several horizontal and vertical sections of a profile pipe, interconnected and forming a broken structure, on which the steps directly rest.

According to the design of the stairs, they are divided into mid-flight, spiral, ladders and side ladders.

marching stairs

Stairs of this type are easy to design and install, as well as the most convenient to use. That is why they are preferred to be mounted in private homes. They consist of one, two or more spans, interconnected by a beam, a horizontally installed transition platform or a section with winder steps. All these options are almost equally popular, and the design of the stairs is selected depending on the area and configuration of the room in which it is planned to be installed.

A single-flight staircase is usually installed in a room with a large area. If it is mounted in a small space, then it is given a significant angle of steepness, and this option is mainly chosen for arranging basement and attic stair passages. Also, single-flight stairs are installed outside the house on a high plinth. In this case, they have a small height and angle of inclination.

Staircase with one march allows you to rationally use the space under the stairs. So, for example, you can install a closet under it, equip a small pantry or even a compact bathroom.

Double-flight stairs, as a rule, are mounted in a specially designated space - a stairwell. This option is used in multi-storey residential, public and industrial buildings, but it is possible to use it in country cottages, provided that there is enough free space. For the greatest space savings, double-flight stairs are often mounted along two walls converging in the corner, i.e. set marches perpendicular to each other. This allows you to equip a small pantry under the staircase.

On long multi-flight stairs (on turns), small platforms are installed that provide structures with greater strength than winder steps. In addition, such designs are safer. Winder steps are resorted to if the space allotted for the stairs does not allow to equip the platform between the spans.

Spiral staircase

This type of stairs is the most aesthetic and economical in terms of space use, but in at the same time, the most difficult for design and installation, as a result of which it does not use a large popularity. The screw design looks very original, and it can fit on a platform of 1500 x 1500 mm. The support system of the stairs consists of a central pillar and a spiral stringer or metal plates, on which trapezoidal steps rest with their wide side.

Despite all the advantages, spiral staircases have one big drawback. It is rather inconvenient to walk on them, and even more so to move large items. Therefore, such structures in private homes are installed only when there is no other way out. Of course, this does not apply to spiral staircases installed in huge rooms, where it is possible to create a spacious structure with long and fairly wide steps.

stepladder

This is a mobile design used on the farm for various needs. The factory-made stepladder is made of aluminum and has the shape of the letter "A". A home-made design can be created from a profile pipe. It consists of two ladders, fastened together by a hinged mechanism. Only one or two halves of the ladder can be equipped with degrees, and it is also possible to have a small folding platform at the top. Fixing the ladder in the open position can be carried out using the crossbar, and the lower ends of the uprights often equipped with tips or jumpers-stops to ensure reliable stability on any surfaces.

Ladder

This is the simplest kind of staircase, which is found in almost any private household. Initially, it was made from a wooden beam, but now there are more and more designs from a profile pipe, which are stronger, more reliable, more durable, albeit heavier than analogues made of wood. It is made no longer than 3 meters, and rubber or plastic tips are put on the supports to prevent slipping on a smooth surface.

How to calculate the parameters of a ladder from a profile pipe

In order for the staircase to be strong, durable and safe, before creating it, it is necessary to make calculations and take into account many nuances. It will not be difficult for a specialist to perform the necessary calculations, since he has experience and the necessary tables at hand, but you can make them yourself using the formulas below and online calculators.

To carry out calculations, you must first determine the height of the flight of stairs. To do this, measure the distance from the floor surface of the first floor to the upper edge of the interfloor overlap.

The marching staircase consists of the following elements:

- kosour or bowstring - varieties of load-bearing support beams for steps;

- tread - the horizontal plane of the step on which the foot is placed;

- riser - the vertical plane of the step or the distance between adjacent treads;

- balusters - posts in the fence on which the railing rests;

- underrail - a hidden bar located between the railings and balusters.

The angle of inclination of the ladder structure should not be more than 40 °, since with a greater steepness of the march the operation of the stairs becomes uncomfortable and unsafe, and the number of steps in one flight can reach up to 16 pcs. Also, the comfort of movement depends on the height of the riser and the width of the step. The following values are established by the norms: 150–200 mm and 200–400 mm, respectively.

To determine the number of steps, it is necessary to divide the height of the span by the height of the riser. After that, determine the projection of the stairs. It is calculated by multiplying the width of the step by their number. Since the width of the flight of stairs must be at least 900 mm, taking into account all the norms, with a ceiling height of 2.5 m, a single-flight staircase will be on the floor, the projection is about 5 m. Therefore, with limited free space in the house, it is recommended to install multi-flight rotary designs.

The calculation is completed by determining the length of the kosour. This can be done using the Pythagorean theorem: L = √ (D2 + H2), where D is the height of the span, H is the value of the projection of the stairs onto the floor, and L is the length of the stringer.

How to choose a professional pipe for stairs

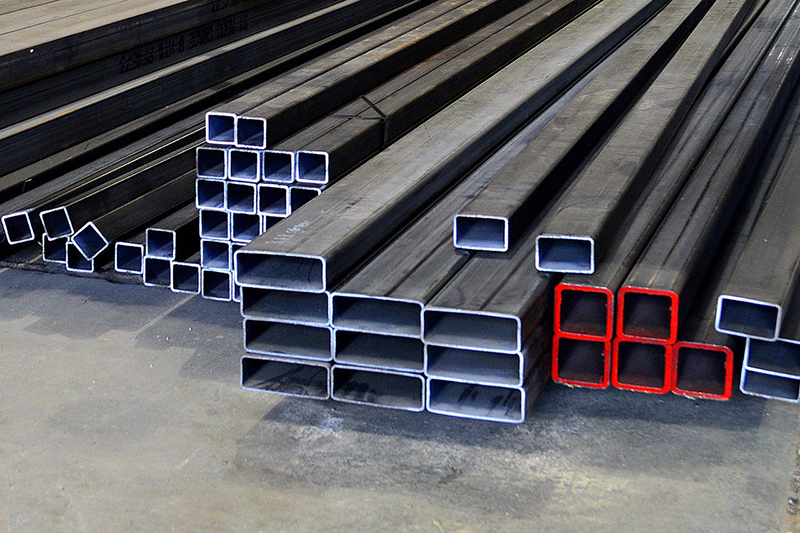

High demands are placed on the ladder frame, because it must withstand heavy loads. To create a support system, a square or rectangular straight-seam profile pipe is used, since it greatly facilitates the assembly of the structure. Profile characteristics directly depend on the type of frame. So, for example, for a small structure on two stringers, you should not use a profile pipe with too thin or thick walls. Due to a thin profile, the ladder will be unreliable, and due to too thick, it will be very heavy.

In order for the staircase structure to withstand daily loads, you need to choose a profile with the following values:

- straight stringer – min. 100 x 50 x 4 mm;

- broken stringer – min. 80 x 60 x 4 mm;

- frame of several parallel stringers – min. 80 x 60 x 4 mm;

- ladder – min. 40 x 40 x 4 or 50 x 50 x 4 mm;

- welded framework for steps – min. 25 x 25 x 3 mm;

- for a ladder, a light profile of 40 x 40 x 4 or 50 x 50 x 4 mm will be sufficient;

- for the installation of a welded frame for steps, a profile of 25 x 25 x 3 mm is suitable.

Check out the table of maximum loads for flights of stairs, depending on their length and the parameters of the profile used.

| The length of the flight of stairs, mm | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 |

| Profile section and wall thickness, mm | Maximum allowable load, kg | |||||

| 50 × 25 × 2 | 684 | 167 | 69 | 34 | 16 | 6 |

| 60 × 40 × 2 | 1255 | 308 | 130 | 66 | 35 | 17 |

| 80 × 40 × 2 | 1911 | 471 | 202 | 105 | 58 | 31 |

| 80 × 40 × 3 | 2672 | 658 | 281 | 146 | 81 | 43 |

| 80 × 60 × 3 | 3583 | 884 | 380 | 199 | 112 | 62 |

| 100 × 50 × 4 | 5489 | 1357 | 585 | 309 | 176 | 101 |

It is necessary to choose the appropriate pipe after the design of the stairs and its basic principles have been determined, as well as all calculations have been made and a drawing has been drawn up.

Do-it-yourself staircase installation

Consider how to independently make a ladder from a profile pipe using the example of a structure on broken stringers with a turntable and winder steps. If you follow the instructions below, then this is quite doable.

Materials and tools

First you need to prepare all the necessary tools and materials:

- profile pipes of the required dimensions and in the required quantity;

- fittings;

- boards;

- round pipe of the required diameter;

- protective composition for wood and metal;

- paint and varnish;

- welding machine and electrodes;

- "Bulgarian" with cutting wheels;

- drill and puncher with a set of drills;

- hammer;

- square;

- roulette;

- building level and plumb;

- grinder;

- clamps;

- spray gun, roller or brush;

- wood saw or electric jigsaw.

You also need to prepare personal protective equipment (tarpaulin suit, gloves, goggles or welding mask, respirator).

Drawings and diagrams

Nothing can be created without a blueprint and an assembly diagram. They indicate the dimensions of all parts, types of connections, corners and the sequence of work.

Preparatory work

First of all, you need to prepare the place where the structure will be installed. In our case, the staircase will be made in the workshop, since it has all the conditions for work.

| Illustration | Action Description |

| Mark the opening on the floor to make it easier to calculate winder steps and not go beyond the existing dimensions |

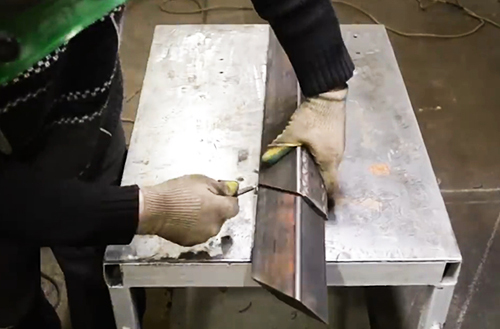

| To facilitate the work, it is recommended to make a template. This will not only simplify, but also speed up the process of manufacturing stairs. Using the template, mark the profile pipe |

| Cut the required number of segments of a broken stringer |

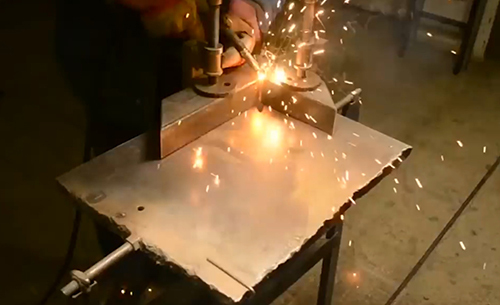

| Set the frame segments at an angle of 90 ° using a square, fix them with clamps and connect them together by welding |

| Increase the segments, thus creating a kosour to the required length. Always check yourself with a square |

| Using a grinder, clean all welds |

| On the stringer, mark and drill holes for fastening the steps |

Ladder assembly

| Illustration | Action Descriptionand I |

| Install the support beams in a predetermined place and weld the bases under the system to them |

| Always check verticals and horizontals with a plumb line and a bubble or laser level |

| In the middle of the structure, where the turn is planned, install a vertical support beam |

| Weld horizontal shaped pipes to the support beam and stringers, which give additional strength to the structure and serve as a support for winder steps |

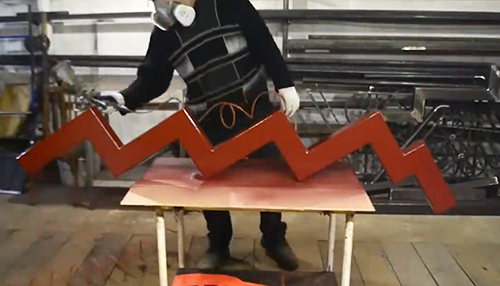

Construction painting

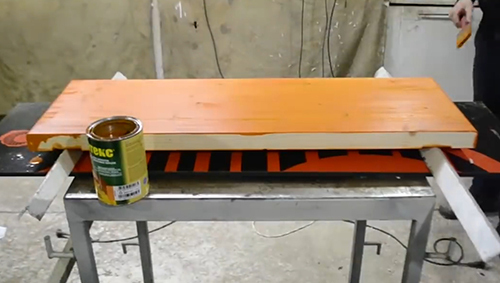

| Illustration | Action Description |

| All metal elements of the stairs are well degreased |

| Next, prime the frame elements, which will give the structure not only durability, but also create a good base for the finish coat. |

| Apply a top coat of the chosen color over the primer. Painting work is best done with a spray gun to get a uniformly painted surface. |

Installation of steps

| Illustration | Action Description |

| To make a tread, take a well-dried board, mark it and saw it into blanks of the desired size. Chamfering wood with a hand saw |

| Try on treads on a metal structure |

| Pay special attention to winder steps |

| After making sure that the treads are cut strictly to size, cover them with a protective primer |

| After the primer has dried, apply parquet or deck varnish |

Installation of fences

| Illustration | Action Description |

| Now you can move on to creating a fence that performs not only a decorative, but also a protective function. In our case, forged elements were ordered for the fence. |

| Using welding, make a fence, linking it to the general structure with the help of "tacks" |

| From a round metal pipe to make support posts and railings |

| Paint the railing in the same way as the entire staircase structure. After checking the fully assembled ladder, disassemble it for transfer to the place of final installation |

| Install the stairs in the stairwell in the house, using powerful anchors. The result is such a strong and reliable staircase with a beautiful railing. |

How to decorate the space under the stairs

There are many options for the design of the space under the stairs. You can simply sheathe it with finishing materials, equip a small pantry, office, closet or even a bathroom. It all depends on the type of stairs, the available space, the preferences and wishes of the owner of the house.

Photo options of finished structures

We offer you to get acquainted with some options for stairs made of metal profiles. You can use these ideas for self-production or develop your own design.

1 out of 12

PHOTO: vanitymagazine.ru

PHOTO: na-dache.pro

PHOTO: dekormyhome.ru

PHOTO: dekormyhome.ru

PHOTO: dekormyhome.ru

PHOTO: www.titaniumstairs.com

PHOTO: zakupka.com

PHOTO: spbrise.ru

PHOTO: zakupka.com

PHOTO: artholl.com.ua

PHOTO: mss55.online

PHOTO: i.pinimg.com

Those who usually suck at life really do not understand a lot of things. And in general they regretted ...

That blogging shit again... Suck on!!!

I just can’t understand: where do juvenile cockerels and swallowers get such incomes from? Who encourage...

Basements in cities and private houses should not be built, they are often drowned. Regarding similar...

There was an idea to buy a country house with a carport. We found an interesting place near the…

We have been wanting to buy a painting on canvas for a long time and recently we were pleased with this by the company Va…

Didn't like the renovation. The kitchen is narrow, it was necessary to visually solve this particular pr…

unlike the palaces of our president's friends, this is just a miserable hut, albeit in style ...

Hello, my name is Andrey. I am buying information sites. There is…

and if the top layer of foam is not broken, then the lacquer surface greatly reduces the hygroscopic ...

strange reasoning regarding sealing. If the log is doused with sealant, foam ...

In the 80s he worked in one NPO, then hammer enamel was sintered. It turned out great,...

While in the summer I lived in the country a lot of different situations I saw and no one fines anyone. Uch…

You won't find a normal apartment for such a sum in Moscow. Even for a country house that …

Thanks. Briefly and clearly...