The modern market for thermal insulation products is rich in assortment. However, some of the most popular materials are expanded polystyrene and mineral wool.

This is justified not only by a low coefficient of thermal conductivity and, as a consequence, an excellent ability to store heat, but also democratic cost, thanks to which both materials remain in demand for a long period of time.

However, when buying, you still have to decide, because you need to buy one thing. But since both materials have similar characteristics, this is not so easy to do.

Therefore, we decided to help you in finding an answer to the question of which is better: expanded polystyrene or mineral wool and have collected comprehensive information about both materials.

What is expanded polystyrene: the pros and cons of the material

Expanded polystyrene mostly consists of air. The percentage of its content reaches 98. And only 2% of the material consists of styrene, into the granules of which, as a result of foaming, air enters.

Due to this high bubble content, expanded polystyrene has excellent thermal insulation properties. After all, many people know that an air gap is an ideal heat insulator.

The finished material is formed into sheets of geometrically correct shape. Their thickness and linear dimensions may be different. Standard dimensions are 1 * 1 meter.

Note! Expanded polystyrene is produced not only in the form of plates. Often, builders produce insulation by spraying a liquid material. But this method is convenient only for those who have specialized equipment at their disposal. After all, you see, few people want to buy expensive equipment in order to use it only a few times.

Of course, the ability to retain heat is not the only advantage of expanded polystyrene. It has a number of other advantages, which include the following characteristics:

- high compressive strength;

- low level of water absorption;

- low weight achieved due to the same material composition;

- environmental friendliness;

- excellent adhesion to various substrates;

- resistance to fungus, mold and pests;

- long service life.

Also, the advantages of the material include ease of installation and low cost.

On a note! By the way, almost everyone can mount polystyrene foam. And you don't need to have special knowledge for this. It is enough to stock up on minimal information about the principles of fastening and subsequent finishing of the insulation. And the matter will remain small.

In addition to the advantages, expanded polystyrene, like any other material, has weaknesses. However, there are few of them, but, nevertheless, they are. So, the disadvantages of expanded polystyrene include:

- poor resistance to sunlight;

- lack of the ability to "breathe" (that is, the material has almost no vapor permeability);

- toxicity in case of smoldering in a fire (hydrocyanic acid, phosgene, styrene will be released into the atmosphere).

In general, expanded polystyrene boards are a very effective heat insulator. However, for all their advantages, they belong to the G3 class, which indicates flammability. Yes, products do not flare up like dry grass, but they smolder quickly enough and at the same time litter the environment. In case of combustion, fire retardants will help to correct the situation, which can be added for the purpose of self-extinguishing polystyrene foam.

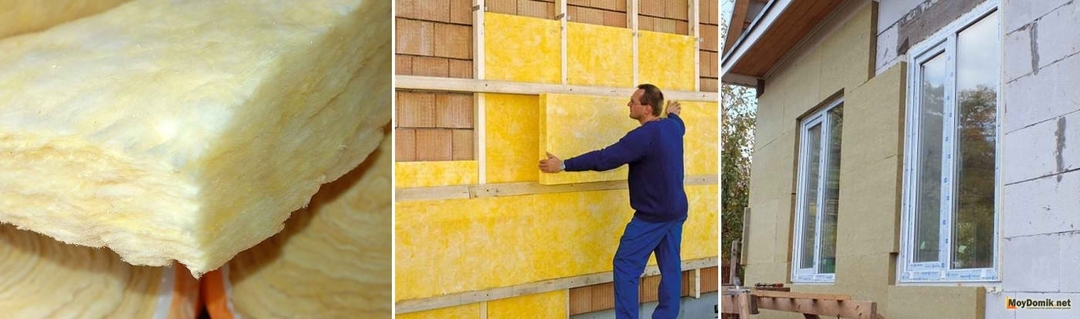

Advantages and disadvantages of mineral wool

Mineral wool is also an excellent material in terms of thermal insulation qualities. It differs from expanded polystyrene in a different structure, represented by fibers.

The thickness of the latter is 4-5 microns with a length of 15-50 mm.

Mineral wool is available in rolls, sheets and mats. The most common size of the slab material is 60 * 120 cm.

It is worth saying that the mineral wool has a classification and, moreover, more than one. The material is distinguished depending on the characteristics of its composition and strength. In accordance with the first criterion, the following types are distinguished:

- glass wool, widely known since Soviet times. Literally everything was insulated with it, from walls in apartments to roofs and communications. Glass wool has a very low coefficient of thermal conductivity, but, at the same time, it has one significant drawback. The fact is that it is literally prickly, so when using it, you can easily cut yourself;

- slag wool produced from blast-furnace slag. Due to the presence in the composition of the latter, such a material has the so-called property of residual acidity. Due to it, being in a damp room, slag wool can adversely affect the condition of metal surfaces. However, if we talk about thermal insulation qualities, then they are quite good. slag wool is capable of retaining heat due to its high heat capacity;

- basalt wool, which is the most modern and demanded subspecies of material. Its main difference from its “brothers” is that it does not contain any binding impurities in the form of slag, glass and mineral components. Basalt wool is perfectly formed into mats, sheets and rolls. It can also be purchased in loose form, but, as a rule, this version of the "execution" of mineral wool is rarely bought.

On a note! We should also highlight stone wool. In fact, this is an analogue of basalt material, but with mineral and binding additives that smolder when burning.

Often, both buyers and builders do not share these concepts, although in fact they indicate different materials. At least, the characteristics of basalt and stone wool, as well as the composition, are different.

As for the classification depending on the density, the mineral wool can have the following indicators:

- P-75. Mineral wool with such a density will insulate various horizontal and vertical surfaces that will not be subjected to significant stress in the future (attics, for example);

- P-125. A material with this density index is excellent for thermal insulation of ceilings and walls, as well as partitions;

- PZh-175. Minvata having a similar numerical value of density is also distinguished by increased rigidity, therefore, it is used when insulating walls and ceilings erected from reinforced concrete or sheet metal;

- PPZh-200. The scope of application of mineral wool with such a density is similar to that described above. But in addition to it, the material with the density of PPZh-200 is often used as protection against fire.

Now let's talk a little about the benefits of mineral wool. So, what is it good for:

- resistance to aggressive environments;

- excellent indicators of elasticity;

- fire safety and resistance to both low and extremely high temperatures (basalt wool can withstand up to 1000 degrees Celsius);

the absence of toxic components in the composition (here, again, we mean basalt insulation).

As for the minuses, they were not without them. However, as is the case with expanded polystyrene, there are not many of them. The fact is that mineral wool is hygroscopic. At the same time, its thermal insulation properties noticeably deteriorate when wet. Another significant drawback is the higher price of basalt material in comparison with the same expanded polystyrene and other types of mineral wool.

We compare materials depending on technical characteristics and properties

Expanded polystyrene and mineral wool, which is better? To answer this question, it is necessary to analyze and compare all the indicators that are important when choosing a thermal insulation material. These include: coefficient of thermal conductivity, fire resistance, environmental friendliness, vapor permeability, ease of installation, service life, as well as resistance to biological, chemical and mechanical impact.

Thermal conductivity

The thermal conductivity coefficient of both heaters meets the requirements of GOST. Therefore, in this regard, the materials, even at the legislative level, are excellent for the thermal insulation of buildings. But if you “meticulously” compare the numerical indicators, then the expanded polystyrene will have them less. The difference, of course, is small, but, nevertheless, it is.

The thermal conductivity coefficient of polystyrene foam varies in the range from 0.028 to 0.034 (W / m * K). Mineral wool has different meanings: depending on the type of material and its composition, the coefficient can range from 0.035 to 0.077 (W / m * K). The conclusion suggests itself: expanded polystyrene, albeit a little, but warmer.

Vapor permeability

The vapor permeability coefficient is one of the main differences between the materials under consideration. Expanded polystyrene is characterized by the presence of an indicator ranging from 0.13 mg / (m * h * Pa) to 0.03 mg / (m * h * Pa). Mineral wool, in turn, has a vapor permeability of 0.4 - 0.6 mg / (m * h * Pa).

This fact indicates that the latter conducts air much better, allowing the walls to “breathe”. And this means that when insulating buildings with mineral wool, the most comfortable microclimate will be established in them, which cannot be said about expanded polystyrene.

What will happen in the premises when thermal insulation is carried out with expanded polystyrene, taking into account its poor vapor permeability? If the installation of an artificial ventilation system is not provided during installation, then in the layer between the main wall and insulation, as well as between the last and the finishing finish, condensation will accumulate due to the difference temperatures. The latter can lead to the appearance of mold, mildew and other adverse effects. But, it is worth noting that this can still be avoided (using the aforementioned ventilation).

Fire resistance

Considering the issue of fire resistance, consumers often doubt which is best for the front door: mineral wool or expanded polystyrene. Many are interested in the option of door insulation due to the fact that during a fire, in addition to windows, you can to get only through it, well, or through an emergency exit, which, as a rule, is present only in public buildings.

We can assure you that neither expanded polystyrene nor mineral wool will block the way to the exit. After all, both materials are not capable of blazing, they can only smolder slowly and, at the same time, emit a very unpleasant odor.

Elasticity

When insulating non-flat surfaces, as well as communications, the bending strength indicator is of great importance for the material. This is not to say that expanded polystyrene does not bend at all, however, you must admit that it will certainly not work to wrap a pipe around it.

This cannot be said about mineral wool, which lends itself easily to almost any transformation. Therefore, in this respect, it is suitable for insulating a wide variety of pipes, columns, complex structures of an asymmetric shape and other elements.

Soundproofing

Sound insulation with mineral wool or expanded polystyrene, which is better? In this respect, the leader is again mineral wool. But it cannot be said that the foam is completely incapable of soundproofing, it is just that this ability is less pronounced in it.

Environmental friendliness and safety

Expanded polystyrene is a safe and environmentally friendly material. Previously, during its manufacture, harmful freon was added to its composition, but over time, manufacturers refused this component.

The composition of mineral wool can include various mineral and binding additives, which include, among others, formaldehydes and phenols. In large quantities, they are dangerous to both humans and the environment. However, in the case of mineral wool, they are harmless, since certain conditions must be created to isolate them (set fire to the material).

On a note! Both materials are completely harmless under normal conditions of use. Although, it is worth noting that in some European countries the use of PPP plates as insulation is prohibited. There is no such ban in Russia. And in our country, almost everything and everywhere is insulated with expanded polystyrene and mineral wool.

Weight

Both mineral wool and expanded polystyrene are lightweight. But if you choose a leader, then the second will definitely win. This is due to the content of 98% of air in the expanded polystyrene, which does not weigh at all.

Biostability

Both materials have good resistance to mold and mildew. But expanded polystyrene, at the same time, is a favorite nesting medium for rodents. Moreover, even the addition of special components to the composition of this material did not solve the problem. Therefore, while this question remains open for producers of expanded polystyrene.

But rodents will not eat basalt. At least if there is at least some kind of alternative.

Mechanical strength

Expanded polystyrene is a relatively durable material. It is not as elastic and flexible as mineral wool, which largely determines its scope. It is, of course, possible to break it, and it is easy to do. But here it is worth considering that this is, nevertheless, a heater, and not a topcoat for walls, floors or ceilings.

Minvata is more elastic. Tearing it apart is difficult enough. It bends perfectly, so it is very convenient to use it to insulate communications, corners with a complex geometric shape, as well as inaccessible places.

Note! The strength and density characteristics of any material are inextricably linked with their ability to store heat. Generally, the higher the density and strength, the lower the heat capacity. Therefore, heat-insulating materials cannot, in principle, possess exceptionally high indicators of resistance to mechanical stress, due to their good ability to retain heat. Simply put, one excludes the other.

Ease of installation

Comparing expanded polystyrene and mineral wool in terms of ease of installation, it is difficult to choose a leader. Both materials lend themselves well to processing, they cut well and are easy to assemble. The only thing is that mineral wool is more versatile when insulated. but this only concerns the shape of the heat-insulated structure, which has already been mentioned more than once above.

Dimensional stability

The geometric dimensions of both heat insulators are stable. Expanded polystyrene, like mineral wool, does not change in size when exposed to heat, and it also does not shrink. In case of deformation, both mineral wool and styrene insulation are quickly restored, taking their original shape and size. But expanded polystyrene with excessive mechanical stress can simply break, which cannot be said about mineral wool.

If we consider the stability of linear dimensions in accordance with GOST, then deviations are allowed, but by a few cm. Much depends on the manufacturer producing the material.

In what cases and how is it better to insulate

The scope of application of materials is determined by their features, which have already been considered by us. Based on them, we will tell you when it is better to use expanded polystyrene, and when mineral wool.

Foundation

If you choose between expanded polystyrene and mineral wool, then when insulating the foundation, it is better to give preference to the first one. This is due to the moisture resistance of the material, which, along with thermal insulation, will protect the base from water.

It is also permissible to use mineral wool, however, at the same time, one should remember about its increased hygroscopicity, which will have to be eliminated by using a waterproofing material.

Floor

The floors are most often insulated with expanded polystyrene. If only because it is cheaper than basalt wool. However, if you do not take into account the price, then both materials are equivalent in the case of thermal insulation of the flooring.

Walls

Which is better: mineral wool or expanded polystyrene for the walls? There is no definite answer to this question. Much depends on the type of premises (residential or non-residential), the localization of the insulation (outside or inside), as well as the finishing option.

So, if the walls are insulated from the facade, then the following nuances must be taken into account:

- preference should be given to mineral wool in case the owner of the building plans to mount siding or any other panel material on top of it;

- if plaster is used as a finishing finish, then regardless of its type, it is better to insulate the building with expanded polystyrene;

- the same applies to the coloring of the building, which in any case will be plastered.

When insulating walls from the inside, both materials are suitable. However, in the case of expanded polystyrene, one should not forget about its poor vapor permeability. Basalt wool will let steam through in any case, but polystyrene foam requires a ventilation device.

But for warming a bath or sauna, expanded polystyrene is perfect. It will perfectly keep the high temperature in the room for as long as possible. In order to avoid increased dampness in the bath, you will have to constantly ventilate the room. And, again, even at the construction stage, ventilation will have to be thought out.

If the bath is insulated with mineral wool, then the situation is fundamentally the opposite: during installation it is necessary to mount waterproofing, otherwise the cotton wool will absorb moisture and let steam through itself.

Ceiling and roof

It is better to insulate the ceiling inside the room with mineral wool, and outside with expanded polystyrene. The same applies to the roof and the attic floor. Although, it is worth noting that builders sometimes do the opposite. And this is quite acceptable if the technology is observed and all the features of the materials are taken into account.

To summarize: what is the best choice?

Expanded polystyrene or mineral wool, which is better? In order to make the right choice, you need to take into account the following nuances and criteria:

- financial component: remember that most subspecies of mineral wool are more expensive than expanded polystyrene (with the exception of expensive brands of extruded type of material);

- the type of room and its features, such as: the level of humidity, the material for the construction of the walls, the need for sound and vapor insulation, and others;

- design characteristics (the presence of irregularly shaped elements, communications that need insulation);

- the purpose of the premises (residential building or, for example, an outbuilding in the form of a garage, bathhouse, basement, etc.).

In other respects, both materials are equally well suited for insulation. After all, it is worth remembering that they are in many ways similar, so the choice, by and large, depends on the consumer.

Reviews and opinions of consumers

Buyers speak flatteringly about both expanded polystyrene and mineral wool. We have collected several reviews on the Internet to show you the subjective opinion of consumers:

- Andrey, 37 years old: “It was not easy for me to make a choice. Trying to figure out what is best for the front door: mineral wool or expanded polystyrene, I re-read a lot of forums and articles on information sites. But, nevertheless, in the end I gave preference to expanded polystyrene and so far I have never regretted it. true, rodents tried to get to it, but after finishing the problem was leveled by itself ”.

- Svetlana, 49 years old: “For insulation, I chose expanded polystyrene, because I subtracted that it has the best heat capacity. We assembled the material ourselves, the process turned out to be very simple. So far, we have not found any shortcomings. ”

- Alexey, 53 years old: “I insulated the attic with mineral wool. As a result, it became noticeably warmer. I even had to turn down the heating intensity because I slept for several days with the windows ajar. It became so warm that even with a bust ”.

- Victor, 35 years old: “Initially I gave preference to mineral wool only because of its sound insulation characteristics, since in terms of heat capacity, its indicators are similar to many other heat insulators. My expectations were met, the noise is much less audible, which makes me very happy ”.

Conclusion

Both expanded polystyrene and mineral wool are excellent insulation materials. When choosing, the main thing is to take into account all the nuances of a room that needs thermal insulation, as well as your own expectations and characteristics of materials.