Experienced plumber intuitively determines the thickness of the winding and the type of seal. When you have a lot of experience, it is not difficult to get the crane in the right position the first time. But experience, as they say, is the son of difficult mistakes. And before it appears, more than one faucet will flow. So it makes sense to take advantage of useful information from the masters who are ready to share their secrets. For example, as the author of the YоuTube channel TheStroiDom

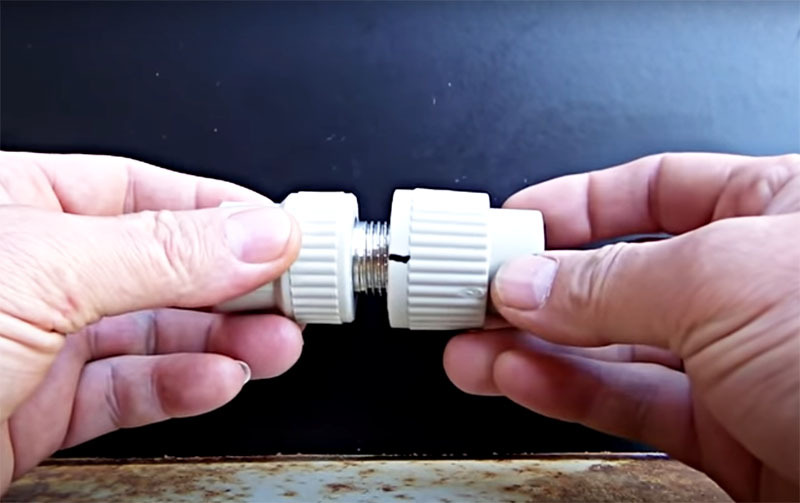

Why you need to twist without a seal first

Many do not attach importance to the features of threaded fittings, and yet now this is the most common and reliable method of connection. Threaded connections are everywhere: in heating and plumbing systems. And the main problem arises when a fitting, angle or faucet needs to be put in a strictly defined position. You miss a little and the line loses the right direction battery will not fall into place.

This happens quite often, and the reason for this is mainly the excessive winding of the seal. This is exactly the case when a lot does not mean good. Therefore, you need to know exactly how many turns of the seal should be made so that the part takes its place, and at the same time the connection does not flow.

To make it easier to count the number of turns, you can put a mark with a marker.

How to wind flax correctly

Why is it about flax? After all, now there are a lot of more modern seals, the manufacturers of which give long-term guarantees. And someone will tell you with confidence that this is the last century. Meanwhile, flax is just the seal that will be more loyal to a beginner in plumbing.

Modern threads and ribbons do not forgive backstop. That is, in case of unsuccessful winding, if you do not want to substitute bowls and basins, you will have to unwind and rewind. Flax, in principle, also does not like the reverse, but will give you a second chance. Well, in addition, it is the cheapest seal possible, not pretentious to the quality of the thread.

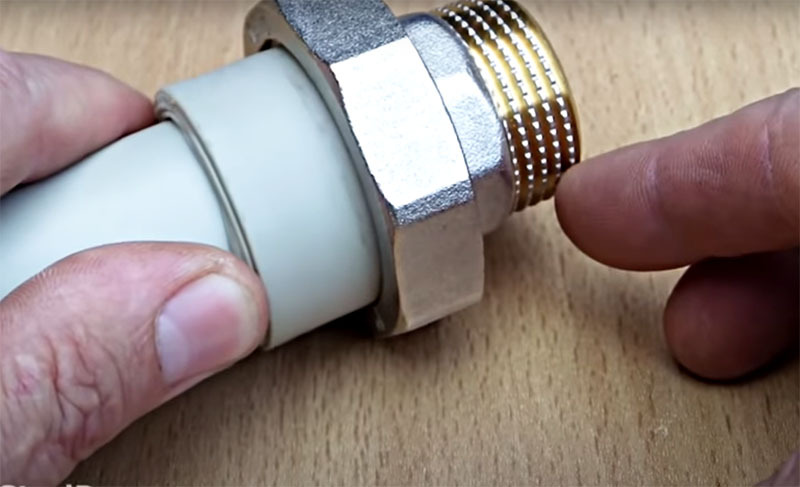

If there are no notches, it is easy to make them yourself using a metal hacksaw, pliers or a regular file.

The winding of the seal must be done in the direction of the thread. The first one and a half to two turns must be left without reeling.

The paste is needed in any case, it will protect the flax from rotting, which all natural materials that come into contact with moisture are exposed to.

It should also be added that it is more convenient to use linen not in bundles, but in spools. It is thinner, easier to wind, and easier to select the desired winding thickness. From pasta - most of all positive reviews about "Unipack". And one more important point: the winding of the seal should not be excessive, otherwise the coupling may burst altogether from excessive load.

And if you are in doubt about the choice of a seal, then here is a small overview video about the features of different types:

What gaskets do you prefer? Do you pre-twist the joints dry? Share your experience in the comments!