Jointer knives get dull pretty quickly, especially if they are in the cheap category. Such a knife needs to be sharpened after each use and the material can withstand a limited number of sharpenings, after which you need to buy a new knife. In principle, there is nothing wrong with this process, if not for one "but". You can hopelessly ruin the knife already with the first sharpening, so it is important to observe the correct angle for dressing. But how can you do this if you do not have a special machine for this purpose? And in principle, is it possible to sharpen such a tool by hand? It is possible, and in practice it was proved by the author of the English-language YouTube channel. Paoson WoodWorking. He offered his viewers a simple hand-held device that allows them to sharpen the blades exactly at the desired angle. You can easily make one for your workshop.

Read in the article

- 1 What is required to make a sharpening tool

- 2 How to prepare knives for sharpening

- 3 Making a blade sharpener

- 4 How to sharpen knives by hand

What is required to make a sharpening tool

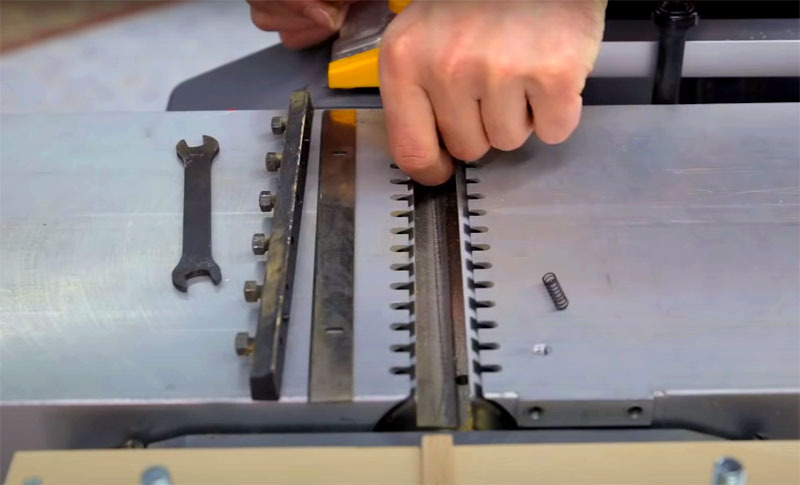

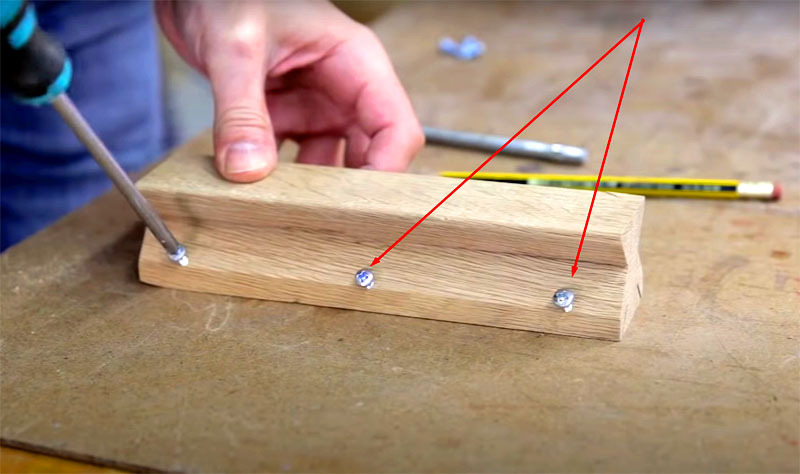

To make a hand tool, you need a block of wood, preferably from a hard wood such as oak. In addition to it, 6 bolts will be useful to you. You need a saw and a drill to cut the tool.

How to prepare knives for sharpening

To sharpen a knife, you must first carefully examine it. If you notice a slight bend on the knife, this is normal, this is done on purpose in order to increase the strength of the blade attachment and increase the rigidity of the cutting edge.

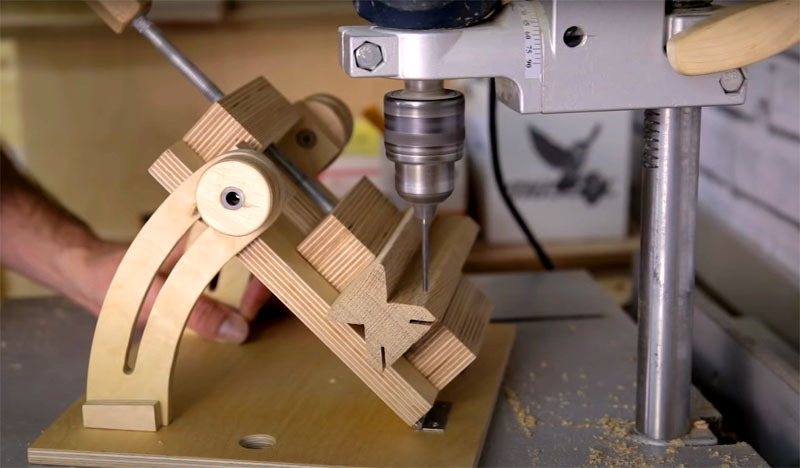

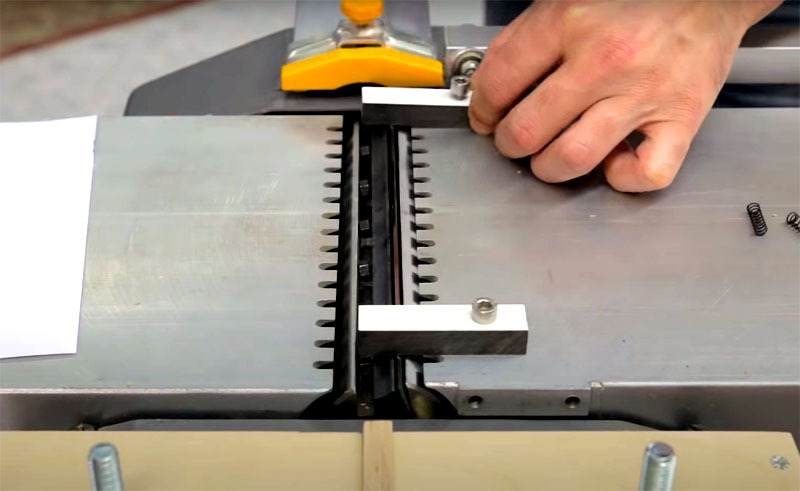

Making a blade sharpener

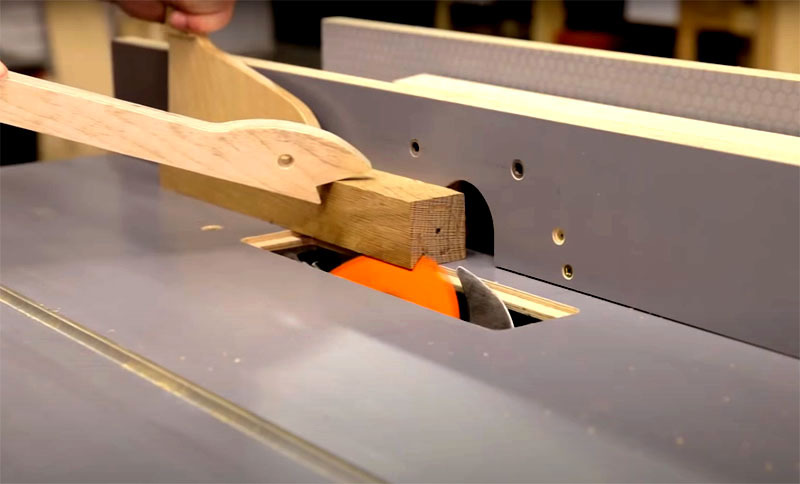

The cutter blade is at a 40 degree angle, so you need to lock it at that angle for sharpening. Just in case, check the sharpening angle with the tools available to you.

How to sharpen knives by hand

It is very easy to check if you have chosen the correct angle on the handheld device.

The second important point is the correct placement of the sandpaper. It is recommended to stick it on glass or perfectly flat stone countertops. For gluing, you can use thin double-sided tape or purchase emery with a ready-made sticky layer on the back.

The device is really very simple and it is quite convenient to use it. The main thing is not to bring the knives to such a position when it will be impossible to edit them. And for this - carefully inspect the boards before work and remove all nails. And here is another option for sharpening the blades, now on the machine:

In this case, the angle of sharpening of the blade can be adjusted by raising and lowering the grinding wheel.

What is your opinion on the manual blade sharpener? If you use a similar one or you have an improved model, write about it in the comments!