If you have to finish the exterior walls of the building, clinker tiles for the facade will be the best option. High-quality durable material is not afraid of negative external influences and has a decent appearance. We offer you to get acquainted with its features, varieties and technology of building cladding.

Read in the article

- 1 Facade clinker tiles - what is it

- 2 Production technology

- 3 Specifications

- 4 Forms of production of clinker tiles for the facade

- 4.1 As individual tiles

- 4.2 As part of clinker panels without insulation

- 4.3 As part of thermal panels with clinker tiles

- 5 Facade clinker tile design

- 5.1 Color solutions

- 5.2 Texture

- 6 Advantages and disadvantages

- 7 Leading manufacturers

- 8 How to choose clinker tiles - recommendations of our editorial staff

- 9 Building cladding technology

- 9.1 Easy tiling on the wall

- 9.2 Ventilated facade organization

- 9.3 Installation of thermal panels

- 10 Facade clinker in the exterior of the house

Facade clinker tiles - what is it

It is a facing material used mainly for facades. In its composition and characteristics, it is similar to clinker bricks, but much thinner. Thanks to this, it can be used to finish external walls without significant thickening of the walls. Has a fairly wide range of applications. It can be used for decoration of private houses and public buildings.

Production technology

In the manufacture of clinker tiles for the facade, a mixture is used based on special refractory types of clay, to which a certain amount of sand, iron oxide and a number of other substances are added. Often, special additives are introduced to change the color of the original mixture.

Typically, such a facing material for the facade is made by extrusion. This technology makes it possible to form a product with a complex configuration. As a result of annealing at a temperature of 1200 ° C, sufficient strength and hardness of the manufactured elements, their resistance to moisture are provided.

Specifications

The dimensions of the decorative elements for the facade may vary. Most often, such a tile is 24 cm long and 7 cm wide. The thickness can vary from 8 to 12 mm. This material for facades is characterized by:

- frost resistance at least 50 cycles. Manufacturers guarantee up to 300;

- water absorption up to 1%. For low grade clinker tiles, this indicator can reach 6%;

- the weight of one piece is 350 - 540 g;

- density within 1400 - 1900 kg / m³.

Attention! The technical characteristics of a particular clinker tile directly depend on the manufacturer.

Forms of production of clinker tiles for the facade

Clinker tiles are available in various formats. Before choosing the right option for your home, you should familiarize yourself with the available products and their distinctive features.

As individual tiles

In its shape and size, such a finishing material coincides with a single, one-and-a-half or double facing brick. This basic tile is complemented by the corner tile used for interior and exterior corners on facades.

As part of clinker panels without insulation

The panels are much larger than individual tiles. Their dimensions depend on the manufacturer. Clinker panels from Gerrad have panels of 60 × 29 cm and 80 × 40 cm. With the help of such cladding, it is easy to create a stone imitation.

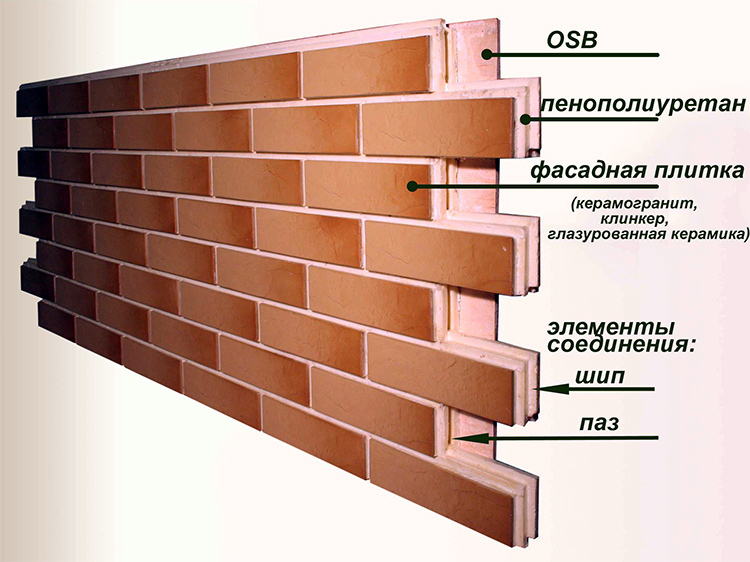

As part of thermal panels with clinker tiles

If it is necessary not only to decorate the facade beautifully, but also to insulate it, thermal panels with clinker tiles will be the best solution. They consist of two layers: insulation and clinker tiles. Depending on the model, expanded polystyrene, polyurethane foam or mineral wool is used as a heat-insulating material, the thickness of which varies between 30-100 mm.

Attention! Thermal panels with polyurethane foam are most in demand.

Facade clinker tile design

The appearance of the finished facade depends a lot on the design of the clinker tiles. Manufacturers offer products with various design options. We invite you to get to know them.

Color solutions

Manufacturers offer clinker tiles in different colors, ranging from gray to burgundy. This greatly expands the possibilities of designers when choosing the right shade.

Texture

Surface texture can vary significantly. Manufacturers offer the following facade clinker tiles:

- smooth. This is the most common type that attracts with ease of care;

- with a relief surface. Such facing material can imitate brick or masonry;

- imitating aged brick, on the surface of which there are characteristic cracks and chips.

Advantages and disadvantages

Choosing clinker tiles for facade decoration, most consumers focus on its undeniable advantages:

- high strength, comparable in value with the strength of porcelain stoneware and natural stone;

- light weight, which greatly simplifies the transportation of the finishing material and its installation. In addition, the requirements for the foundation of the finished building are reduced;

- low level of moisture absorption, amounting to about 1-6%, depending on the model;

- frost resistance. The porous structure ensures the timely removal of moisture outside the tile, which prevents it from freezing inside the material;

- long service life, averaging half a century;

- resistance to atmospheric precipitation, ultraviolet radiation;

- preservation of geometric parameters after significant temperature fluctuations;

- resistance to aggressive environments. Clinker tiles are not afraid of alkali and acid;

- biostability, hygiene. No fungus or mildew forms on the surface of the facade;

- uniform pigmentation of clinker tiles, making cracks and chips that appear during operation invisible;

- high adhesion to the base due to grooves on the inner surface;

- versatility. Clinker tiles can be used to decorate the facades of buildings built from different materials;

- a large assortment. Available in a choice of colors and designs;

- ease of installation and subsequent maintenance;

- environmental friendliness. There are no harmful substances in the composition of clinker tiles;

- fire resistance.

Among the shortcomings, it is worth noting:

- high cost of finishing facades with clinker tiles;

- fragility. If the installation technology or operating rules are violated, the clinker tiles may collapse;

- the need to correctly calculate the dew point when installing panels with insulation.

Leading manufacturers

High-quality clinker tiles are made by many manufacturers. Leading positions are traditionally occupied by products of a number of German manufacturers:

- WesterWalder;

- Feldhaus Klinker;

- D.W. Klinker;

- Korzilius;

- Penter Klinker and several others.

Among other European companies, the products of the following companies deserve attention:

- Gresmanc from Spain;

- KingKlinker from Poland;

- Vandersanden from Belgium;

- ST-Joris from the Netherlands.

Among domestic manufacturers, the products of "Ideal Stone", Keralite and a number of others are of interest. In terms of its operational characteristics, such a finishing material for the facade is not inferior to imported counterparts.

How to choose clinker tiles - recommendations of our editorial staff

In order for the facade cladding to last longer, it is worth approaching the choice of clinker tiles with all responsibility. First of all, you should pay attention to the density. The higher the value, the stronger the material will be.

The color of the facade surface must match the color of the roof. With a successful combination, it is possible to enhance the decorative component of the facing material. Otherwise, the effect will be reversed. The texture of the front surface of the finish deserves special attention. The more complex it is, the more beautiful the facades will look.

Building cladding technology

The procedure for performing installation work directly depends on the goal pursued. We offer you to get acquainted with the technology of simple installation, the organization of a ventilated facade and the installation of thermal panels.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

"If clinker tiles are purchased from different batches, the elements should be mixed before installation so that the shade is uniform over the entire area.

Easy tiling on the wall

Before the beginning finishing works the walls are carefully leveled. At the same time, the integrity of the base is necessarily ensured. All existing irregularities, delamination are removed with the help of a reinforcing mixture. The plastered surface is additionally primed and dried

Attention! The drop of 1 m² should not exceed 2 mm.

After that, the work is performed in the following sequence:

| Illustration | Description of action |

| The markup is in progress. The upper edge of the door or the lower edge of the window most often acts as a beacon. The spatial position of the laid row is controlled using a level. A metal profile is attached along the marking line, which is used as a starting bar and prevents the lower row from displacement due to gravity |

| An adhesive composition is being prepared. It is imperative to ensure the mixing ratio specified by the manufacturer. The finished composition is applied to the substrate with a notched trowel. |

| A 1 mm thick layer of adhesive is applied to the mounting side of the decorative element to be glued. |

| Each element is carefully pressed to the base, fixing in the correct spatial position. Plastic spacer crosses provide the required clearance |

| The subsequent rows are being laid. The thickness of the gaps between the rows is 10 - 14 mm |

| Corner bases are designed with corner pieces. In this case, their position on the opposite side is necessarily controlled with the help of a level. |

Ventilated facade organization

The procedure for organizing ventilated facade radically different from the order of installation of conventional tiles. Watch the following video to understand the intricacies of the process:

Installation of thermal panels

Facade cladding is performed in the following sequence:

- Preparation of the base. If alignment is difficult, a wooden or metal frame is mounted to which the thermal panels will be attached.

- An aluminum profile is attached to the bottom. It will act as the starting bar. A similar element is attached at the highest point of the wall.

- Installation work is carried out from left to right, starting from the corner panels.

- The first panel is attached and fixed with self-tapping screws and screws.

- The next thermal panel is inserted into the strip. At the same time, its spikes are treated with polyurethane foam or sealant.

Attention! The next row can be mounted only after the completion of the first one.

We suggest watching the following video in order to understand in detail the order of installation work:

Facade clinker in the exterior of the house

To evaluate the appearance of the facade finished with clinker tiles, we suggest looking at the following photos. Perhaps among them there is a suitable option for decorating your home.

1 out of 4

Share in the comments if you have ever used clinker tiles for facade decoration? Are you satisfied with the result you received?