The range of finishing materials for interior work on the shelves of Russian construction stores is very large. However, home craftsmen are increasingly choosing natural materials. This is natural, because a person is always drawn to nature, everyone wants the family to live in the most environmentally friendly atmosphere. One of the most demanded materials for interior decoration is imitation of a bar. It is about the cladding and installation of a false timber inside the room with your own hands today and will be discussed.

Read in the article

- 1 What is imitation timber: what does this material look like?

- 2 The choice of a raised beam: what you should pay attention to

- 2.1 Types of wood for imitation of timber on the Russian market

- 2.2 Deciduous tree species and their uses

- 2.3 The type of wood used for the manufacture of false beams

- 2.4 Panel sizes suggested by the manufacturer

- 3 How to calculate the amount of imitation timber needed for finishing

- 4 Compositions for processing imitation of timber for interior decoration

- 5 Do-it-yourself installation of imitation of a bar: how the sheathing is performed

- 5.1 Tools and materials for attaching a false beam to the wall

- 5.2 Algorithm of actions when installing an imitation of a bar indoors

- 6 Several options for interior decoration with imitation of a bar in photo examples

- 7 Final part

What is imitation timber: what does this material look like?

Imitation of a bar is a type of lining, which is made from natural wood. Externally, the material may look like a regular (or rounded) timber, which is also called a block house. Although in fact it is almost identical material. Moreover, if you do not look closely, it may seem that the wall does not have any finishing at all. This gives the room a natural look.

Imitation of a bar is used for external cladding of facades, interior walls and ceilings. This material can be painted, varnished or waxed. Here everything is at the discretion of the master or owner.

The choice of a raised beam: what you should pay attention to

When purchasing an imitation of a bar for interior decoration, you should pay attention to 3 main parameters - the type and type of wood, the size of the panels and the company that produces this material. As for the manufacturer, we can say the following - always, before any purchase (finishing materials are no exception) it is worth talking to those who have already used imitation of a bar, and it also makes sense to get acquainted with the opinions of users networks. Better to lose a couple of days on familiarization than after "biting your elbows."

Types of wood for imitation of timber on the Russian market

There are two types of wood used for the manufacture of false beams - these are coniferous and deciduous trees.

Among conifers, pine, spruce, cedar or larch are used. Each of the breeds has its own advantages and disadvantages. For example, pine is easy to process, there are few knots on it, but over time it turns yellow, and after that it even darkens. Larch is more often used for exterior decoration. Its resins contain antiseptic substances that prevent rotting and the appearance of mold, but larch is very heavy. Recently, Altai cedar has been increasingly used to make imitation of timber. This is probably one of the few wood species in which it is difficult to find cons. Distinctive features of cedar are weather resistance, dense structure, amazingly beautiful pattern and almost complete absence of knots.

Deciduous tree species and their uses

Most often you can find a false timber made of linden and oak. But if the oak is resistant to ultraviolet light and has sufficient strength, linden does not have such characteristics. Therefore, it is more often used for finishing saunas and baths. Sometimes you can find an imitation of aspen timber, but this is very rare. And the fact is that the core of this tree is subject to decay, which does not improve the quality of products made from it.

The type of wood used for the manufacture of false beams

Like almost any product, imitation of a bar is divided into grades. Let us analyze which false beam is better to purchase, and which one should be discarded.

The list of varieties will go from the most expensive to the cheapest:

- "Extra" - panels with a perfectly smooth surface, without stains, rot. Maximum one knot per panel. Unpolished parts are allowed, but only on condition that they will not be visible after installation.

- "BUT" - knots are present, but they should not fall out, there is no decay, mold, wormholes. Stains are possible that occupy no more than 10% of the surface.

- "IN" - no rot. Dead knots (up to 10 mm) may come across. Wormholes are allowed, but no more than 3 per panel. Blues and stains are also allowed.

- "WITH" - the lowest grade of wood, in which holes, dead knots, not planted areas, wormholes are allowed. Such a false beam is used only for painting with opaque paintwork materials.

It is interesting that in the Russian market it is extremely difficult, and sometimes even impossible, to find products of the "Extra" variety. This is used by negligent sellers, passing off products of category "A" as the highest grade.

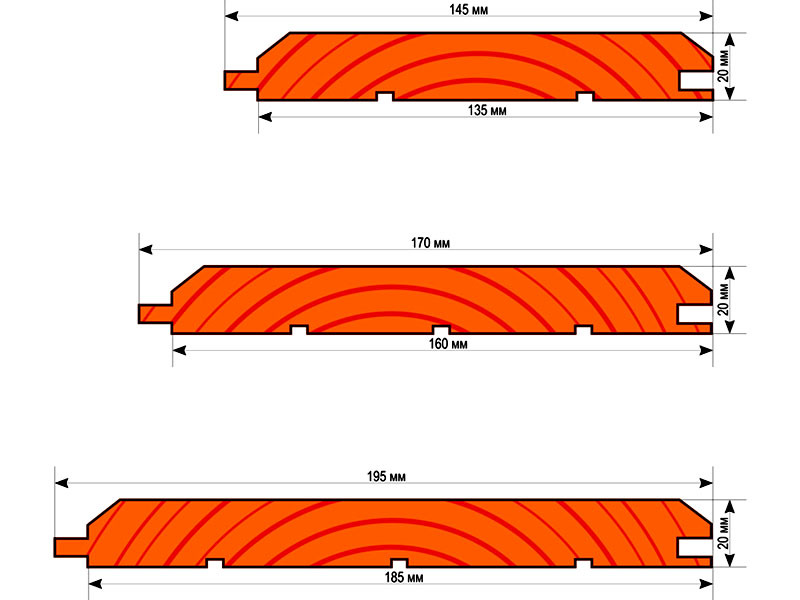

Panel sizes suggested by the manufacturer

The most common are the following trim panel sizes:

- length - 2.5-6 m;

- width - 1.1-18.5 cm;

- thickness - 1.6-3.5 cm.

However, the manufacturer meets the buyer halfway, and therefore today on the market wider panels are also offered, which significantly reduce the installation time.

How to calculate the amount of imitation timber needed for finishing

In order to calculate the number of false beam panels, it is necessary to clearly define their width and length. And then there will be nothing complicated. Having calculated the total surface area (excluding windows and doors), it is necessary to divide it by the area of one panel. However, you should not buy the material "back to back". It is necessary to add at least 20, or even 30% to the result obtained for insurance.

If the seller does not have the required number of panels available, you should not hope to buy them from another. The entire false beam must be from the same batch. Otherwise, over time, the color of one batch will change more than the shade of the other, which will not have the best effect on the appearance of the wall.

Compositions for processing imitation of timber for interior decoration

Before using a similar material for interior decoration, the panels are impregnated with antiseptic compounds that prevent the appearance of fungus, mold, insects. However, this is not enough for the false beam to retain its original appearance for a long time. After installation, the surface is coated with wax or varnish. Stains, if they appear over time, are removed using special compounds designed for natural wood.

As for leaving, everything is simple here. Periodic removal of dust from the surface is sufficient. However, it is worth remembering that such a finishing material is afraid of excessive moisture.

Do-it-yourself installation of imitation of a bar: how the sheathing is performed

Such work cannot be called simple, but there is nothing super complicated in it. Let's try to figure out how the panels are attached to the walls inside the house, in detail. To begin with, it makes sense to understand what tools and materials will be needed to create the interior of a log house.

Tools and materials for attaching a false beam to the wall

In order to fix the false beam on the wall, you will need the following materials:

- slats with a side width of at least 5 cm for mounting the battens;

- insulation and vapor barrier material;

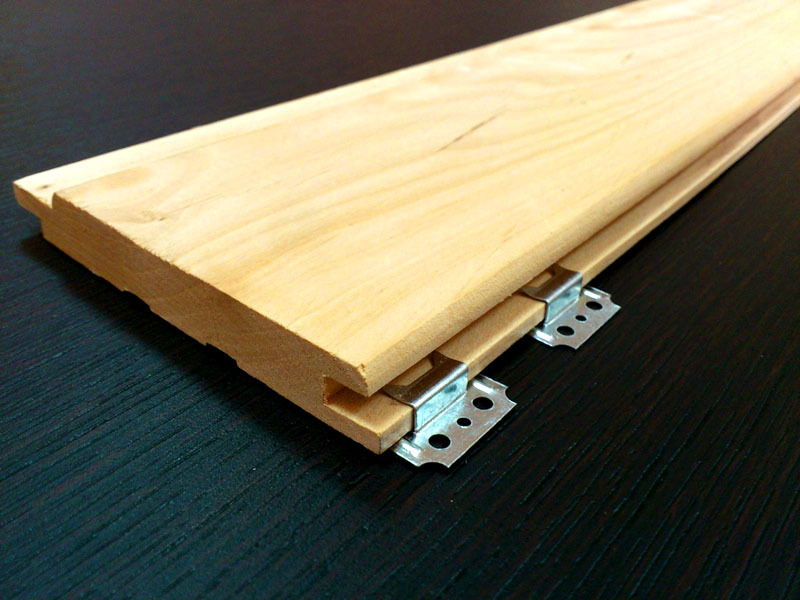

- fixing elements - these can be nails, screws or clamps.

The tool is the simplest - a perforator, a hammer, screwdrivers (screwdriver). Let's try to consider step by step the technology for installing imitation of a bar inside the room.

Algorithm of actions when installing an imitation of a bar indoors

First you need to decide on the type of installation. In this case, it will be very convenient to use special clamps - clamps. However, to speed up the process, it is better to use a pneumatic nailer, or a nail gun, as it is also called.

| Illustration | Action being performed |

| The first thing to do is to fix the lathing bars on the wall, previously treated with an antiseptic. For concrete and brick surfaces, the use of a metal profile is allowed. The step of the lathing is 3-4 cm less than the width of the insulation, so that the plates fit tightly. The voids are filled with mineral or basalt wool. |

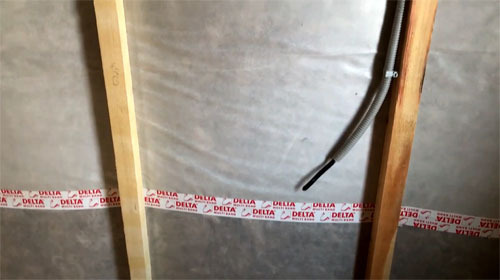

| Next, using a stapler, a layer of vapor barrier is attached. You can ignore small irregularities in the surface, they will not interfere in further work. |

| Places where one strip of vapor barrier material is superimposed on another are glued with special adhesive tape. It is also sold in hardware stores and markets. |

| Now you need to assemble the counter-lattice. The bars are attached to the main grill on top of the vapor barrier. This is necessary so that there is a gap between the insulation and the imitation of the timber. Then the air here will circulate freely, which will create the necessary macroclimate in the room and prevent mold and mildew from developing. It will also be possible to install electrical cables and other utilities here. |

| The easiest way to fix the panels to the counter-lattice is to use a pneumatic nailer. Special cassettes of nails are loaded into its clip; in this case, their length is 60 mm. |

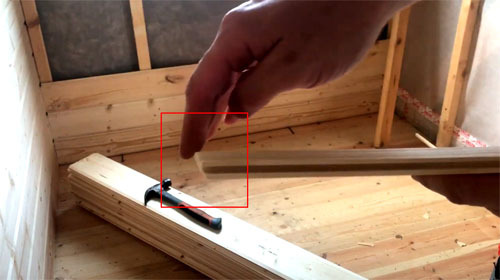

| In order to protect yourself from squeaking when walking on the floor, nails are placed under the lower panel, which is attached first, providing a small gap between the wall and the floor. Installation of panels starts from the bottom. |

| In the corners it is necessary to exclude gaps. To do this, one of the sides of the panel is cut at an angle. In this case, the imitation of the timber will fit perfectly. |

| As a result, it should look something like this. All panels are fitted, it remains to lay the skirting boards and moldings and cover the false timber with a protective layer. However, do not forget about the junction boxes, which are also hidden. |

| The junction box is recessed under the imitation of a bar, and the cut hole can be covered with a decorative ventilation grill. |

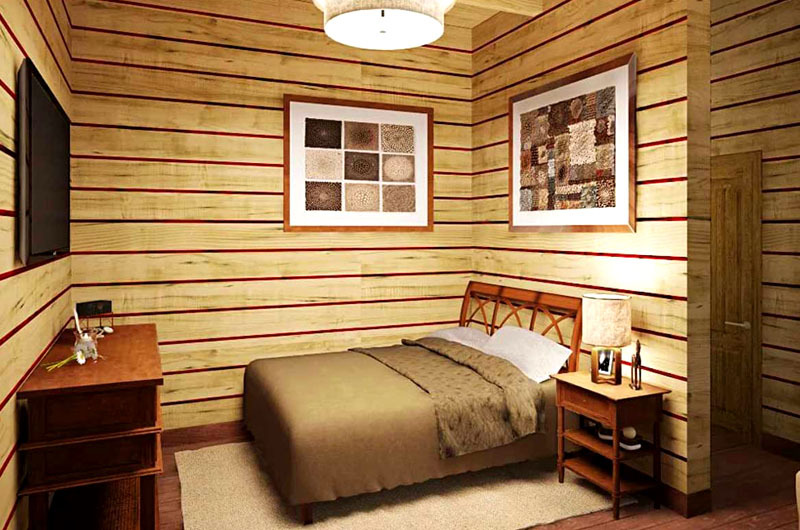

Several options for interior decoration with imitation of a bar in photo examples

Such a finish is suitable for almost any room in a country house. Imitation of a bar allows you to feel at one with nature, creates a feeling of naturalness even in concrete and brick buildings. Here are some photo examples of similar interior decoration.

1 out of 6

PHOTO: roomester.ru

PHOTO: dekoriko.ru

PHOTO: eurolesmarket.rf

PHOTO: studiominibrusa.rf

PHOTO: roomester.ru

PHOTO: roomester.ru

Final part

Sheathing and installation of imitation of a bar indoors is not a very simple and fast process, but quite exciting. After all, it is very interesting to modify a simple bare wall to the state of an ideal natural array. At the same time, additional insulation is organized, which is important. Of course, it is difficult to call such a finish cheap, but with proper installation and proper care, you can enjoy the interior, feeling as if in a forest house, for many years. On average, for an employee without any experience, a room with an area of 5-7 m2 can be finished in a couple of days. And this is if only one person will work. As for aesthetics, here it is at the highest level.

We really hope that today's article will be useful to our esteemed home master. HouseChief editors will be happy to answer your questions, if any, during the reading process. All you have to do is explain them in the discussions below. There you can also comment on what you read, express your personal opinion about such a finishing material as a false beam. Also, don't forget to rate today's article. Your opinion is extremely important to us - it will help us develop in the right direction. And finally, we bring to your attention a short but very informative video that will help you to more fully reveal today's topic. Take care of yourself, loved ones and be healthy!