During the operation of the power tool, an abnormal situation may occur at any time (overheating of the engine, breakage of the drill or disc, jamming, etc.). The most common problem when working with angle grinder (angle grinder) or grinder - clamping cutting or grinding disc. In today's HouseChief review, we'll show you how to unscrew the clamping nut if it gets stuck.

Read in the article

- 1 Spin the disc in the opposite direction

- 2 Retaining flange heating

- 3 Nail to help you

- 4 Using an adjustable wrench

- 5 Rotary hammer or impact drill

- 6 Tapping the nut

- 7 Disk destruction

- 8 Flange sawing

- 9 Preventing disc seizure

- 10 A few words in conclusion

Spin the disc in the opposite direction

This method is good because you can unscrew the locking flange without a standard wrench and even with a broken spindle lock. Novice locksmiths often believe that if the stopper is broken, then the nut will be impossible to unscrew using conventional methods. This is a misconception, since you don't even need the key that comes with the angle grinder.

The essence of the method lies in the fact that the grinding or cutting wheel needs to be given short-term sharp rotations in different directions. To do this, it is necessary to put on tight work gloves, preferably leather, and sharply hit the working edge of the consumable several times. If it did not work out the first time, you need to repeat the operation. Usually 2-3 such blows are enough to unscrew the lock nut of the grinder.

Retaining flange heating

This is one of the easiest and most effective ways to replace a cutting disc on a grinder when there is no special key nearby. The lock nut must be heated with a hot air gun, a gas torch, or by pressing it hard against a block of wood. Once the flange is sufficiently hot, it can be easily squeezed out with a hand protected with a welding glove. However, this method has one drawback: there is a risk of damaging the plastic case of the angle grinder.

Nail to help you

Another effective way to unscrew the clamped nut on the grinder if there is no key. To do this, you need a nail with a length of 100 mm, from which you need to bite off the cap, and then give it a U-shape. The distance between the ends of the nail must match the holes in the clamping flange of the angle grinder. Insert the resulting structure into the holes of the nut and turn it. If the flange does not give way, then you can use a screwdriver as a lever or pliers.

Using an adjustable wrench

The use of an adjustable wrench of the "toad" type in order to unscrew the clamped disc on the angle grinder has its advantage due to the increased lever. Be aware, however, that applying too much force can damage the spindle stop and the pressure flange.

Rotary hammer or impact drill

Honestly, it is not the best and easiest option to unscrew the clamped nut on the grinder, but it is used if other methods do not work. As an attachment for a drill or hammer drill, you need a drill of a suitable diameter, most often 6 mm. If a drill is used, then you need to put it in the jackhammer mode in advance. It is better to fix the grinder in a vice, clamp the spindle stopper, insert the drill into one of the holes of the clamping nut with an emphasis in the direction of unscrewing, and briefly press the "Start" button. This method allows you to move even a tightly clamped flange. The disadvantage is that you can break the bore holes for a standard wrench this way.

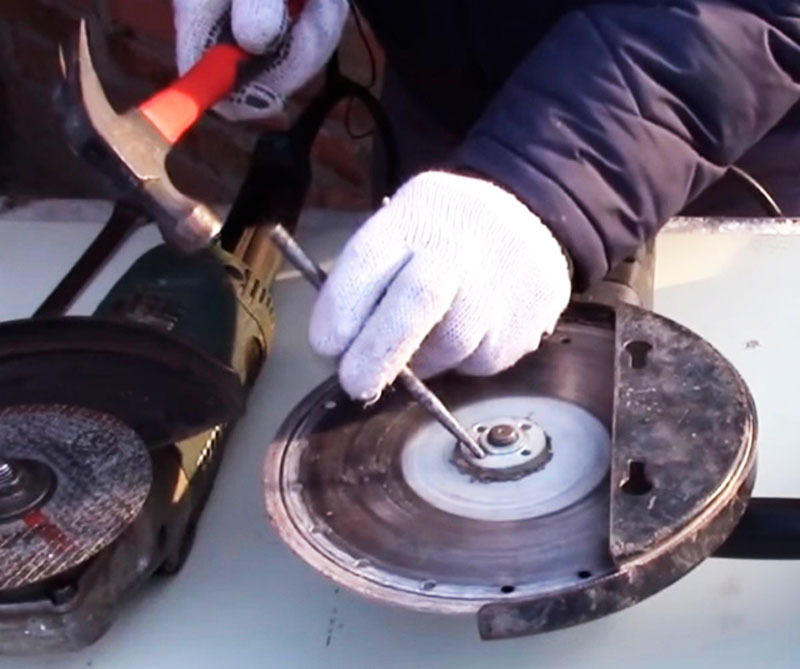

Tapping the nut

This method is similar to the previous one, with the difference that instead of a hammer drill or hammer drill, a chisel or metal rod of a suitable diameter is used. Having locked the grinder's spindle, you need to insert the rod into the hole in the nut and tap it with a hammer in the direction of the wheel's movement. By slightly moving the flange from its place, it can be unscrewed by hand. This method has the same disadvantage as when using a hammer drill.

Disk destruction

The cardinal solution for unscrewing a clamped lock nut is the destruction of the disc. It is necessary to break the disc with pliers or pliers. As a result, a ring and hard-to-reach fragments will remain. Next, you need to take the largest piece of the disc and clamp it in a vice, with the cutting edge up. Now grind off its remains and the ring on this shard. After that, you can easily unscrew the clamping nut with a standard wrench that comes with the grinder.

Flange sawing

Another radical way to remove a tightly clamped nut on an angle grinder, if other measures did not help, is sawing. This option should only be used as a last resort and provided that you have a spare flange. Some models of grinders from well-known manufacturers are equipped with an additional clamping nut.

Preventing disc seizure

We figured out how to unscrew the clamped nut and change the disk to the angle grinder, and now we will consider how to safely operate the grinder so that this problem does not arise anymore. This requires:

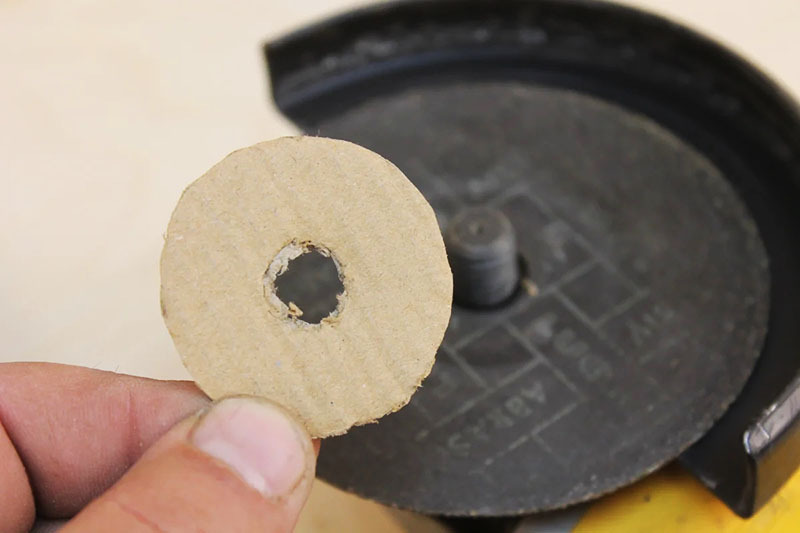

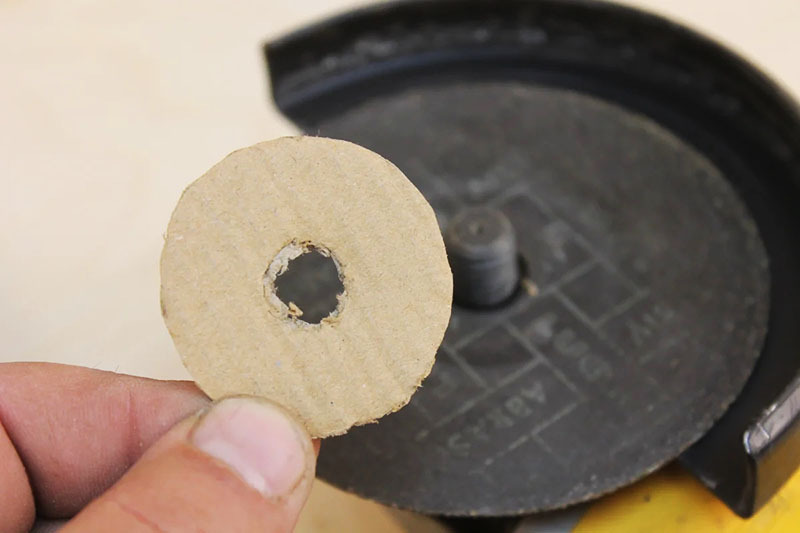

- Place cardboard, rubber or plastic washers between the nut, the spindle head and on both sides of the disc. They will not allow the nut to be tightened too tightly and significantly reduce the likelihood of tool jamming, and if clamped, they can be easily and quickly removed and the clamping flange unscrewed.

- Install the cutting or stripping disc correctly. It must be mounted face-down on the spindle head.

- It is advisable to weld a regular nut onto the clamping flange, which will allow you to use a regular wrench in case of jamming.

- Check the tightening force of the clamping nut. Excessive force will cause the tool to stall under heavy load.

A few words in conclusion

An angle grinder is a multifunctional tool necessary in any household, but "biting" the clamping nut is the most common problem when using a grinder. We have considered the most effective ways to solve it, but maybe you have your own options. Share with us and other readers how you unscrew the clamped nut of the grinder.