CONTENT

- 1 What is catalytic oven cleaning

- 2 Pyrolytic oven cleaning - what is it

- 3 Hydrolysis oven cleaning - what it is and how it works

- 4 The traditional way to clean the oven - what is it

- 5 What type of oven cleaning is best

- 6 Which oven cleaning is best, according to experts

What is catalytic oven cleaning

Many users cookers with oven read in the instructions for the purchased equipment about the presence of such a function, but do not understand what it is - a catalytic type of cleaning. In order to understand the essence of the process, it is necessary to get acquainted with the features of this technology, which is increasingly being equipped with modern stoves that have an oven.

FOR YOUR INFORMATION!

The principle of operation is to cover the walls and blades of the fan with special enamel, which has a porous structure that is invisible to the eye, but its properties are similar to blotting paper.

What does catalytic oven cleaning mean? During the cooking process, a lot of fat builds up on the inside of the oven. For its high-quality removal, the process of chemical decomposition is activated. As a result of this chemical reaction, the following components are released:

- carbon;

- organic;

- water.

Fat-absorbing substances located on the porous surface of the enamel are responsible for regulating the decay process. To implement such a cleaning method, it is required that the enamelled part includes the following components:

- absorbent containing nanoparticles;

- special backing;

- oxidizing agents required to catalyze a chemical decomposition reaction.

FOR YOUR INFORMATION!

The best quality oxidizing reagents are copper oxide, cobalt, cerium dioxide or manganese. Typically, the active ingredient is applied to the top and back of the oven, and they are also contained on the blades.

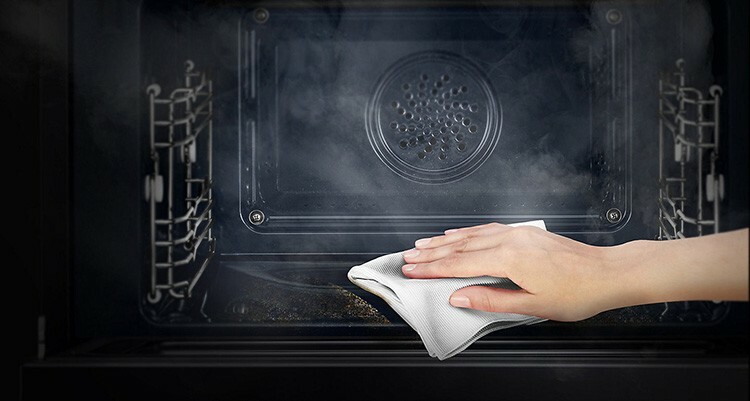

One of the positive features of the process of catalytic cleaning of the oven, according to customer reviews, is the absence of the need for human participation in the process. To get started, you only need to heat the oven to a certain temperature. Most often, the beginning of cleansing occurs when it reaches 140 ° C, and the best efficiency is achieved at 200-250 ° C. After finishing cooking, the hostess only needs to wipe the surface with a damp cloth to make it look like new.

Oven catalytic cleaning system: pros and cons

Any technology has its own advantages and disadvantages, the knowledge of which allows you to make the right choice when purchasing new equipment. The oven cleaning system also has its pros and cons. The positive features of the method are:

- fully automated start-up during cooking;

- saving energy, time and energy;

- versatility, which makes it possible to use the technology in any type of oven;

- the presence of a special coating practically does not affect the cost of the finished product;

- the principle of manufacturing catalytic enamel is unchanged, therefore, any brand of stove will have characteristic qualities;

- all manufacturers have ovens in their model range equipped with such a function, so there will be no problem of choosing.

The disadvantages of this method should be highlighted:

- lower cleaning efficiency when compared with other methods (hydrolysis or pyrolysis);

- the bottom of the oven and the surface of the door do not have catalytic properties, since the coating is sensitive to the ingress of sweet or dairy products;

- maximum efficiency can be achieved only with frequent use, since it is not possible to clean up strong pollution at a time;

- the average service life of the catalytic plate is 5 years, after which it needs to be replaced.

Features of catalytic ovens

A technique that has similar functions has a number of specific features. They should be taken into account when deciding to purchase a catalytic oven:

- It is worth preventing the ingress of sugar or dairy products on the surface of the enamel, since they can spoil the active layer. This is why the base of the oven is not enamelled. Therefore, you will have to clean it manually using household chemicals or grandmother's recipes.

- The question often arises as to which type of oven cleaning is best. It can be immediately answered that the priority does not belong to the catalytic method, since it is less effective than other methods. When cooking, a large amount of fat can be released, which is not cleared the first time, which causes it to burn in the future.

- The wall coating material is sensitive to abrasives, therefore, to maintain its integrity, it is required to use soft sponges and products devoid of large particles that can spoil the surface.

- The service life of the catalytic panel is 5 years, after which it needs to be replaced. This is done independently according to the instructions from the manufacturer, or you can contact the service center specialists for help.

FOR YOUR INFORMATION!

Some manufacturers produce double-sided panels. If the cleaning qualities of the protective surface decrease, you should simply turn them over with the back side.

In addition to the panel system, the oven can be equipped with special grease filters that prevent the formation of a large amount of plaque on the walls, which reduces the duration of the catalytic panel process in repeatedly. The filters are easy to clean, only the oil is first drained from them.

Pyrolytic oven cleaning - what is it

The next way to get a clean inside of the oven is the pyrolysis cleaning process. What it is? The essence of the method lies in the name itself, since in translation from Greek "feast" means "heat", and "lysus" means "decay". In other words, this technology is called thermal decomposition, since the inside of the oven must be heated to at least 450 ° C to remove the remaining fat. Under the influence of such high temperatures, all organic compounds simply burn out with the formation of ash, which is simply removed from the oven with a cloth after it has cooled down.

IMPORTANT!

The pyrolysis process is only possible in electric models, since gas devices are not able to heat up above 250 ° C.

Advantages and disadvantages of the method

This method also has a number of invaluable advantages, which are side by side with disadvantages. They should be taken into account if you wish to become the owner of an oven with pyrolysis cleaning. The advantages of the method are:

- high efficiency. When choosing which method of cleaning ovens is better, pyrolysis confidently takes a leading position, because through this technology it is possible to get rid of even the most old and strong pollution;

- versatility, allowing the removal of all types of plaque;

- cleaning the entire area of the oven, which is especially important to remove dirt in places where, using another method, only manual cleaning would be needed;

- no need to use household chemicals, after which there is a plaque and an unpleasant odor that affects the quality of food.

The disadvantages of this cleaning method can be considered:

- higher cost of equipment with pyrolysis, which is due to the use of heat-resistant types of steel and specially tempered glass to withstand high temperatures;

- the duration of the cleaning process, which can last up to 2 hours;

- energy consumption, the value of which depends on the degree of pollution, but on average varies from 4 to 7 kV;

- requirements for the surrounding furniture, which must also withstand higher temperatures;

- the presence of an unpleasant odor. An oven equipped with a pyrolysis function has special filters to trap odors, but with heavy pollution, they simply may not cope with the assigned task.

How to use pyrolysis correctly

In order for the pyrolysis cleaning process to be of high quality, a number of rules must be observed, which also ensure the safety of others during the procedure:

- It must first be removed from the oven. trays and racks, which are simply not designed for such temperature conditions.

- When choosing a specific model, you should pay attention to the presence of a door lock function, which should be activated when the temperature rises to 200 ° C.

- We recommend cleaning at least once a month to avoid significant carbon build-up. Many modern stoves are equipped with a special catalyst that determines the degree of contamination and notifies the owner of the need for cleaning.

IMPORTANT!

Even if there is a blockage in inexpensive models, significant heating of the glass is observed, therefore, it is advisable not to let children near the stove during cleaning.

Hydrolysis oven cleaning - what it is and how it works

Another method of cleaning the inside of the oven is hydrolysis, or steam cleaning of the oven. What it is? The method involves the use of a special reagent called a hydrolysis fluid. It is poured into the drip tray and the oven turns on. The gradually generated steam begins to settle on the walls and leads to a softening of the fatty deposits. Further, the natural drainage of fat into the pan with liquid occurs.

IMPORTANT!

In case of severe contamination, this method is not enough, and the final cleaning will have to be done manually.

The main requirement for modern ovens equipped with a hydrolysis cleaning function is the manufacture of surfaces from high quality acid resistant enamel to keep grease out of the device.

Advantages and Disadvantages of Steam Cleaning

Knowing what it is - cleaning the oven with steam, allows you to highlight the advantages and disadvantages of this method. They also need to be considered when choosing a new oven for the kitchen. The advantages of the method are:

- simplicity of the method;

- low cost;

- implementation of the process without the use of aggressive reagents;

- the cleaning procedure takes place at low temperatures, which allows you to preserve the surface of the oven.

The disadvantages of the process are:

- the need to use a rag or sponge to remove softened fat;

- self-cleaning of additional elements;

- inability to remove old fat.

How to properly carry out hydrolysis cleaning

The process of hydrolysis cleaning of the oven, called AquaClean or AquaSmart, takes place in several stages:

- All additional elements, such as baking trays, racks, fasteners, should be removed beforehand.

- Further, the required mode is selected on the control panel and the cycle is set with the support of such technology.

- The required amount of liquid is poured into a tray or a special recess in the bottom of the oven.

During hydrolysis cleaning, you will need to remove all additional elements from the oven - After the end of the vaporization process, allow the oven to cool slightly and clean the surface with a clean, soft cloth.

FOR YOUR INFORMATION!

Budget models of stoves are not always equipped with a special tray for water, therefore, the steam cleaning process in them can be carried out by pouring liquid into heat-resistant dishes, which are installed on the grate.

The traditional way to clean the oven - what is it

Perhaps the last method to get the inside of the oven clean is the traditional method, which involves the use of industrial detergents, a sponge or rag, and your own hands. According to most housewives, this method is the most costly in terms of time and effort. To obtain purity, not only store-bought formulations are used, but folk recipes (lemon juice, vinegar, soda) can also be used.

Advantages and Disadvantages of the Traditional Method

When talking about the mechanical method of removing fat and dirt, the disadvantages should be listed first, since they are more obvious than the advantages. The disadvantages of this method include:

- the mechanical nature of the work;

- separate cleaning of all parts, including the door;

- products containing an insufficient amount of abrasive do not remove grease well, and the use of powders can ruin the surface;

- harsh chemicals leave a smell.

The advantages of this type of cleansing are:

- minimal costs, since the purchase of a special oven is not required;

- no spending on electrical energy.

How to clean the oven with "grandma's" methods

In the kitchen of each housewife there are components that allow you to clean the oven in the traditional way. These include:

- soda;

- vinegar;

- salt;

- lemon.

From water, vinegar and soda, you can prepare a solution that cleans old fat well if you leave it on the surface for two to three hours and then remove it with a rag. Ordinary vinegar can be used for steam cleaning by leaving a heat-resistant container inside the oven and heating it to 200 ° C. The use of citric acid involves mixing it with a little vinegar. The resulting solution should be used to treat the walls, which are preheated to 100 ° C. Another component for preparing a cleansing paste is hydrogen peroxide, which is mixed with baking soda. The resulting composition is applied to the walls for 4 hours, after which it is washed off with a sufficient amount of water.

What type of oven cleaning is best

The presence of a large number of ways to clean the oven poses a choice of which one is the most effective. There is no single answer here, since each housewife chooses a method that is convenient for herself. The only thing that can be noted is that the traditional method is the least popular.

Which oven cleaning is better: catalytic or steam

In this "duet" the palm belongs to the catalytic method, since its application allows cope with even the most stubborn fat, without the need for significant investment in time or electrical energy. Steam cleaning is only useful when fresh fat is present and needs to be cleaned quickly. But here gentle household chemicals will come to the rescue.

Which oven cleaning is better: catalytic or pyrolytic

Comparison of these two methods, in which cleaning is carried out by means of a temperature regime, will be in favor of pyrolysis, since this technology allows you to completely clean the surface. oven without human intervention. Even in spite of strict safety and equipment requirements, pyrolysis is a more effective method.

Which oven cleaning is best, according to experts

A large number of methods for cleaning the oven can be confusing for an inexperienced housewife. The presented video will allow you to once again hear the opinion of experts in order to determine for yourself, which method of obtaining a perfectly clean oven surface will be most effective and optimal.