Fencing made of corrugated board is not only a modern solution, it has a number of advantages over other options and that is why it is in great demand. How to choose a corrugated board? What to consider in the process of building a fence?

A fence made of profiled sheet is a practical and cost-effective way of fencing a land plot

What is a professional sheet

Content

- What is a professional sheet

- Advantages and disadvantages

- Varieties of protective coatings

- Zinc

- Aluzinc

- Polyester

- Plastisol or Pural

- Types of metal profiles

- C 8

- From 10

- From 14

- From 15

- C 18, C 20, C 21

- What to consider when choosing a professional sheet

- What to look for when buying a professional sheet

- Material calculation

- Video: How to make a fence from corrugated board with your own hands

- Photo: Examples of finished fences from a profiled sheet

Profiled sheet (or corrugated board) is a metal sheet made of galvanized steel. produced by the cold method on special machines. The profiled sheet repeats the shape of the wave and, due to this, retains its rigidity. This material is actively used for cladding houses and for the construction of fences.

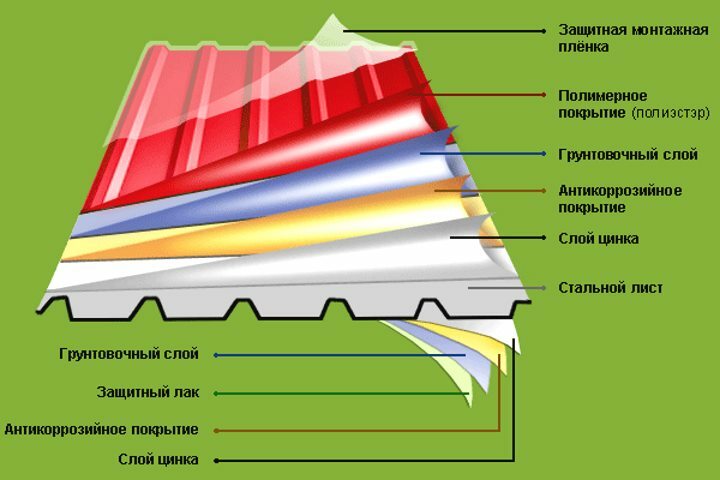

The structure of the profiled sheet with a protective and decorative coating

Standard corrugated board has several layers:

- The base is made of low-alloy steel.

- Zinc layer.

- Anti-corrosion compound.

- Primer.

- Colored polymer: usually a composition of synthetic resins and plastics.

Alternatively, instead of colored polymer, the profiled sheet is covered with plastisol. In this case, the material becomes even more resistant to environmental influences, but it also costs an order of magnitude higher.

The protective polymer coating can imitate wood or stone

Advantages and disadvantages

Like any building material, the profiled sheet has its own strengths and weaknesses.

Advantages:

- Affordable price. A fence made of galvanized profiled sheet will cost you much less than a fence made of a wooden picket fence, or a forged structure.

- The protective coating prevents the material from fading or developing corrosion on its surface. The professional sheet retains its original color throughout the entire period of operation.

- The service life of the corrugated sheet fence is up to 50 years.

- The surface is easily cleaned of dirt, and if there is damage to the paint layer, this place is simply cleaned and again covered with a dye composition.

- The material is offered in a wide range. It is possible to choose different colors of corrugated board for the fence. By the way, if you are not a supporter of monochromatic fences, choose corrugated board for a fence under a tree. It looks very nice.

- If desired, such sheets can be easily combined with brick, stone, polycarbonate and forged elements.

- Installation requires a minimum of time and effort.

- The finished fence is durable and reliable.

A fence made of corrugated board with a polymer coating imitating natural stone

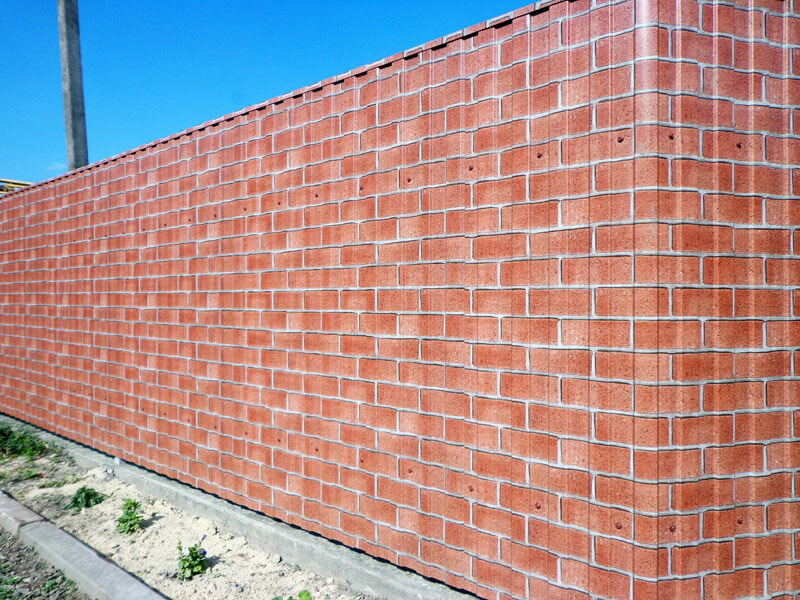

Fence made of profiled sheet with imitation of brickwork

The disadvantages include the impossibility of installation by welding, since the outer coating is damaged under the influence of high temperatures.

One of the main factors affecting the anti-corrosion resistance of the sheet is the zinc coating. The service life of the material depends on its thickness and method of application. Such a coating does not have a tangible effect on the weight of the sheet, but it seriously affects the quality. So to say, a directly proportional relationship: the more zinc, the higher the quality and the longer the period of operation.

Varieties of protective coatings

Since the corrugated board is a multi-layer structure, its durability and strength depends on each layer. If the most expensive coating is applied to low quality steel, the result will be depressing. The same is true for poor quality coverage and a good base. And yet, each of the offered coatings has its own characteristics, which are recommended to be taken into account when choosing a corrugated board.

The service life of the fence and its decorative properties depend on the choice of a protective coating.

Zinc

Budget option, galvanized steel sheet. It is not highly reliable. It is not often used for fencing private houses, but it is ideal for protecting large factory areas, or construction areas. Differs in presentable appearance and affordable price.

A fence made of a simple galvanized sheet is the cheapest option for fencing

Aluzinc

Composition, which includes aluminum and zinc, in a ratio of 55% to 45%. It looks more advantageous than just a galvanized sheet. And yet, the main area of its application is the fencing of industrial zones and construction sites.

The protective coating Aluzinc (AZ), in comparison with simple galvanizing, gives an increase in the durability of steel sheet by 3-5 times

If desired, it can be painted, but financially this is impractical, since high-quality paints are not cheap, and such work will cost many times more than buying a finished painted sheet.

Polyester

If you are looking for material for building a fence around your home, choose a corrugated sheet with a polyester coating. It is dirt-repellent, weather-resistant, chemically inert, and cannot be damaged even by a solvent. The glossy surface always looks clean and well-groomed. If there are drops of dirt or smudges, they can be easily washed off with a jet of water from the pump, or just wait for the next rain - and your fence is like new again.

Polyester coated profile sheet for longer service life

Plastisol or Pural

The most durable coating of all of the above. A significant drawback is the high cost. Typically used in premium construction. The service life is measured in many decades.

And having calculated how many times you have to change a fence made of ordinary corrugated board, you may decide that the material coated with plastisol is not at all as expensive as it seemed at first. Everything is relative.

Profile sheet with polymer coating plastisol

Types of metal profiles

It is only at first glance that the entire corrugated board is "in one person", in fact it is not. Mainly, the material differs in wave height.

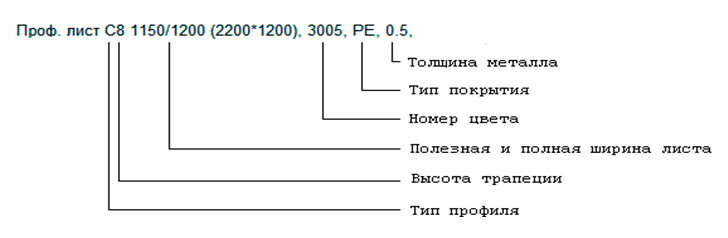

Profiled sheet marking

Universal profiled sheet, which can be used for both roofs and fences, is marked with the designation "HC". The material used for the construction of roofs or slabs is called load-bearing and is marked with the letter "H".

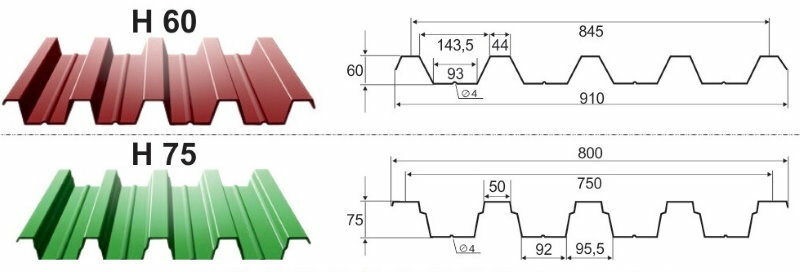

Universal professional flooring NS-18, 21, 35, 44

Wall corrugated board of the N-60, 75 brand

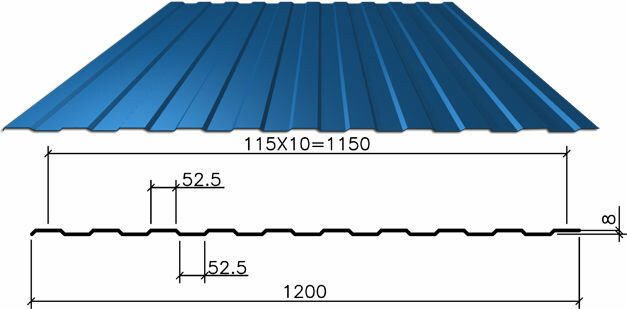

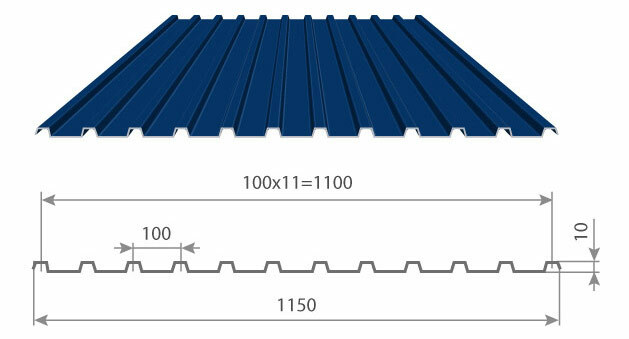

Profiled sheet for fences is marked with the letter "C" (wall version), and then a number indicating this height follows. The higher the number, the greater the thickness, and, as a result, the stability of the fence.

C 8

In this case, the wave size is only 8 mm. This is the lightest and cheapest option of all the brands presented. Such a sheet is suitable if you need to protect a large space for a short period. It is not recommended for long spans or high fences. But it is perfect for decorating buildings outside.

Profile sheet with C-8 marking

From 10

A fairly cost-effective option for a fence. In terms of strength, it is somewhat superior to professional sheet C 8, and costs a little more. This grade withstands gusts of wind and high snowdrifts.

Profile sheet with C-10 marking

From 14

Perhaps the most popular professional sheet. Tough enough. It is perfect for the construction of fences near country houses. The perfect combination of price, quality and decent appearance. Often, such a corrugated board is "in harmony" with brick elements (pillars, for example).

Profile sheet with C-14 marking

From 15

A distinctive feature is the width of the rib. The cost is slightly higher than that of previous brands, and the installation technology is practically the same. No additional tools or skills required.

Profile sheet with C-15 marking

C 18, C 20, C 21

These grades provide the highest reliability due to the highest stiffening ribs. Such a profile can be installed with spans of different widths and heights, it can easily withstand gusts of wind and precipitation. Visually, the fence made from the profiled sheet of these brands is somewhat different from the generally accepted fences from the C 14 sheet. The external roughness of the structure is easily balanced by a brick foundation.

What to consider when choosing a professional sheet

The choice of sheet is influenced not only by the height and length of the future fencing, but two more main factors:

- Terrain relief.

- Climatic conditions.

If your future fence is not high, and there is no strong gusty wind in your area, then professional sheet C8 or C 10 is quite suitable for you. If you need to protect the space with a high fence, and there are winds, choose the C 17 professional sheet. Finally, when the wind load is very strong, buy material marked C 21 - this is the most reliable option in the "C" series.

The variety of colors of the profiled sheets allows you to choose exactly the shade that will harmoniously fit into the surrounding landscape

There is one more important feature that should be taken into account. Each brand of corrugated board differs in its width. At the time of acquisition, the difference seems imperceptible, but during the editing process, it becomes obvious. So, a fence of one length of profiled sheet C 21 will require more than material marked C 10.

What to look for when buying a professional sheet

- External characteristics. For example, if you buy a profiled sheet of non-standard width, this is a serious reason to think about whether the rolled metal is actually made in accordance with GOST.

- Top layer quality. The corrugated board must not have scratches, dents or paint peeling.

- The cut deserves special attention. The presence of "burrs" is unacceptable, this is a sure sign of "clandestine" manufacturing. High-quality equipment does not allow such "mistakes".

- Geometric waveform. Bends should be the same, constantly repeating. An important nuance: the boundaries of the waves should be clear.

- Availability of a guarantee. Only a manufacturer of high-quality rolled metal products will provide a guarantee for their product. If there is no guarantee, this is a reason to think: Is it worth buying anything from this manufacturer at all?

The simplest version of the fence made of corrugated board

Material calculation

To determine the volume of materials, you need to make the following measurements:

- Determine the overall perimeter of the fence. If you plan to make a gate and a wicket, then subtract their width from the total perimeter.

- The resulting value is divided by the width of one sheet. If the result is a fractional number, it is rounded up to the nearest integer.

- When purchasing material, provide one spare sheet.

If you have not determined the working width in advance, then, having determined the total width of the sheet, subtract from it the width of the two "waves" (this is provided that you will overlap the sheets).

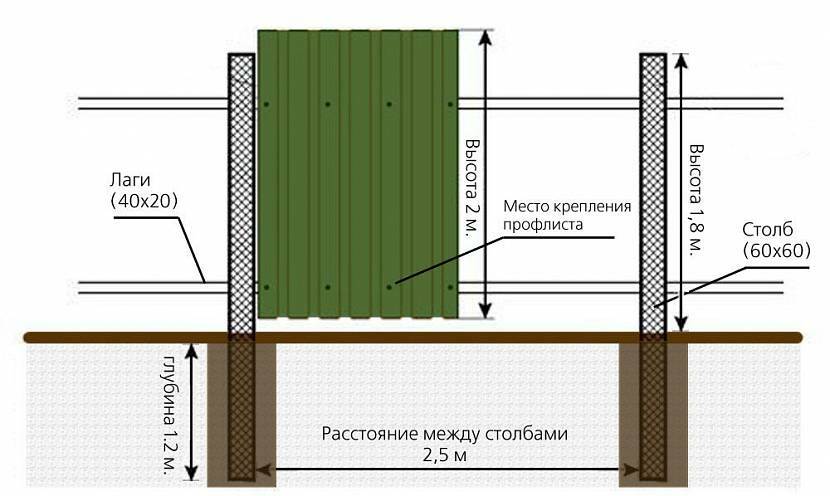

The classic version of such a fence consists of pillars, sheathing, transverse pipes and fasteners. If we take into account the average human height of 175 - 185 cm, then the height of the leaf should exceed it by 10-15 cm. This means that the minimum height of the fence will be 2 meters. In some cases, owners prefer to make a fence 2.5 or even 3 meters high. This will provide protection from prying eyes and a reliable shelter from gusts of wind. It should be noted that sheets of 3 meters high are made to order.

Standard fence made of corrugated board on metal poles

If the main purpose of your fence from the profiled sheet is only to mark the boundaries, or in the case when there are no neighbors, you can make the fence lower, for example, 1.8 meters.

When calculating the height of the pillars, take into account the height of the fence, and the fact that they must be dug into the ground by 1 - 1.5 meters. The number of cross posts is determined based on the perimeter of the fence. For a profiled sheet with a height of 2 meters, the transverse pipes are mounted in two rows.

Corrugated fence with brick pillars

Fence made of profiled sheet, decorated with forged elements

Someone underestimates such rental because of the democratic price, but, as you can see, the profiled sheet can have a very expensive coating and not cheap. And yet, today it is the most demanded building material. It is appreciated for its ease of use and resistance to different climatic conditions.