Even 5-10 years ago, underfloor heating can be safely described as expensive. Water heating, which uses a floor heating, element considered luxury. Such a method of heating in most cases installed in the elite housing. Today the situation has changed radically. Water floor becomes commonplace. A growing number of consumers prefer it to this embodiment, residential heating. The main reason for the popularity of water warm floors - it is their efficiency, affordable price and high efficiency.

Also appeared on the market supplies of heating equipment, instruments and devices to be equipped with their own heating floors in your home, saving both money and time. You can always choose materials that meet the technological parameters of the heating system and your personal requirements to such a method of heating. If the equipment included in the kit pump-mixer unit underfloor heating, a separate conversation, the pipes are particularly noteworthy.

Despite the fact that today the selection of consumables is great enough, preference is given to an embodiment, when the floor heating is done polypropylene tubes. Why? Let us examine in detail.

Main article about polypropylene tubes.

Heated floor - the characteristics of this heating system

To begin with, the floor heating can be used as the main heating variant in a living room or act as an additional heat source. Depending on the technological characteristics of the residential buildings, which use a heating option in the case of under-floor heating, you decide. For an apartment in the house a warm floor can be an exception. In some cases, the inhabitants try using heated tiled surface to increase comfort in the bathroom or in other technological areas.

Important! It should be recalled, the current ban on assembly and installation of warm water floor in a residential area of apartment buildings. The reason for this situation lies in the lack of preparation of engineering designs of residential homes for the installation of a complex heating system, which is the water floor.

In the situation, when it comes to installing the "warm floor" heating system in a private home, no restrictions and obstacles to the implementation of the project no. Possible installation and installation of underfloor space in any different combination ..

For those who still dare to laying the floor heating in its housing, it is important to be aware of the necessary equipment and supplies. Pipes for any water heating systems are the main operating member. It is for them prepared water circulates, transferring thermal energy heat sources. This can be a radiator or in case of floors with water heated concrete screed, composing a wooden floor structure. heat transfer from the heat medium through the floor heating circuits water. The material from which is made a water pipe loop depends speed of installation of underfloor heating pipeline and quality of the floor surface.

Why today for underfloor heating circuits selected polypropylene?

To date, the company - manufacturers are ready to offer consumables for all tastes. It all depends on the financial capacity of the consumer. On the practical side for floor heating equipment, you can use the following types of pipe:

- copper;

- corrugated, metal;

- metal and plastic;

- a consumable material from a crosslinked polyethylene;

- Polypropylene.

Either option has the right to sell, but here comes in the factor of efficiency and technological feasibility. Polypropylene pipes in this aspect seem preferable in many ways. Why today, many consumers prefer consumables made of polypropylene.

Underfloor heating pipes made of polypropylene is currently the most popular option. The whole point is price. When installing large-scale heating systems, when it comes to water floors with a total pipeline length of several hundred meters to the fore the economic component. Polypropylene heating circuits in this respect are a good solution of the problem.

The following options can be safely attributed to advantages such Consumables:

- the necessary mechanical strength and elasticity of the polypropylene tubes;

- necessary for leaks;

- durability;

- high technological characteristics, simplifying installation of heating circuits;

- low cost.

It should focus on a couple of points. Polypropylene is highly resistant to low temperatures. Freezing the coolant in the conduit will not result in mechanical damage to the heating circuit. Such a tube is suitable for underfloor heating, equipped cottages and country houses, where the heating system works intermittently.

Special welding method provides polypropylene pipes for leaks. The pipeline, laid in the concrete floor, can safely operate in normal mode than a dozen years. By following instructions and stacking technology, you can make a warm floor in your home for a long time forgetting about its design and on the device.

For reference: in accordance with the instructions to products polypropylene tubes capable of withstanding the working temperature of the coolant to 750C at an operating pressure of 7.5 atm. According to the passport products, polypropylene pipe can be used 25-30 years.

Assess the merits of this option, do not forget about the negative aspects of polypropylene heating circuits.

Important! Polypropylene has performed in a conventional high coefficient of thermal expansion, so the thickness of screed to be installed in concrete pipe made reinforced polypropylene tube.

The main drawback of the consumables on the basis of polymers, are poor-quality raw materials and non-compliance with installation work technology. In other words, the tube is often encountered in which a result of the extremely high temperatures observed swelling of the upper layer. Bending water circuit may be configured correctly, excluding the coefficient of thermal expansion of the material.

Features of the application of polypropylene pipes for underfloor heating equipment

Simple polypropylene tubes usually used for water and sewage pipes. Underfloor heating systems use a simple polypropylene pipe dangerous from the point of view of non-compliance products thermal and hydraulic loads. Underfloor heating is better to establish on the basis of reinforced pipes. Such a product has all the characteristics peculiar to this method heating. The channel is triple-layered. Between the inner and the outer layer is a polypropylene reinforcing layer made of aluminum foil or a woven filament (fiberglass).

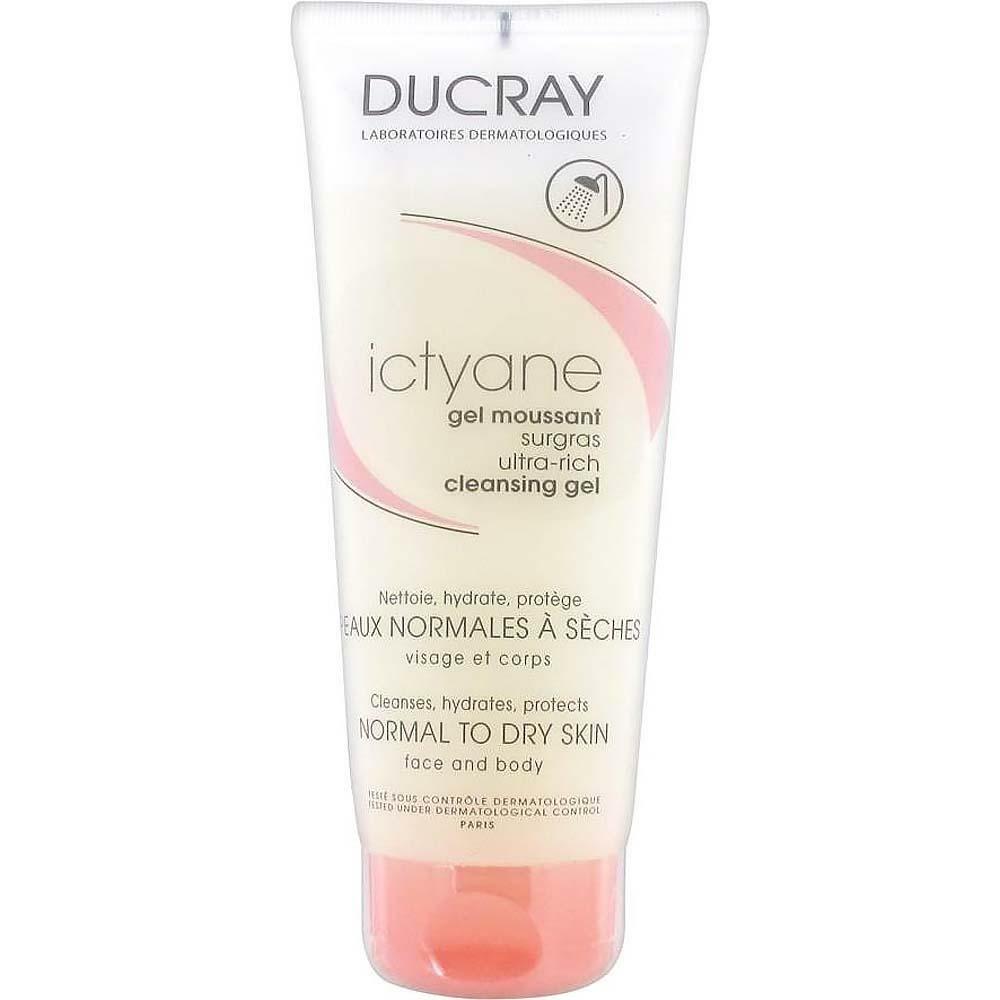

The photograph shows two variants of the manufacture of pipes with an aluminum layer and glass fiber in the middle.

The presence of the reinforcing layer allows free pipeline, immured in the concrete floor to withstand temperatures up to 950C and the water pressure to 10 atm.

Existing marking tubes of polypropylene

In order to avoid errors during the process of installation, should deal with the existing marking on polypropylene products. Today, the company - manufacturers offer the market the following types of polypropylene pipes:

- PN10, marking, which stands on the conventional product with a homogeneous polymer structure. These supplies are conventional hardware water systems at operating temperature in water of 200C and operating pressures up to 10 atm. The diameter of such a tube typically ranges 20-110 mm.

- PN16, marking the corresponding homogeneous product which can be used for the installation of warm water floor. Acceptable coolant temperature setting should not exceed 800FROM. Permitted operating pressure - 10 atm. The outer diameters of similar type articles PN10, but in this case there is an increased thickness of the pipe walls.

- PN20, a uniform marking for pipes in which hot water circulation temperature is allowed to 950FROM. There may be already working pressures up to 6 bar. Pipes produced with diameters 20-110 mm.

- PN20 AL (PN20 GF), marking for polypropylene, which is present in the reinforced layer of aluminum or of glass fibers. For all other parameters, these products comply with the PN20 marking pipes. The main difference from other consumables, a lower coefficient of thermal expansion (thermal linear expansion factor).

What nuances must be followed when laying pipes polypropylene

What would make radiant floor heating in your home efficient and effective, it is necessary to make preliminary estimates of the number of tubes required for installation. Thermal and hydraulic calculations will help you put the right water heating circuit and connect all heating equipment in a specific sequence.

Working with polypropylene, it is better to focus on laying the scheme: the snail. Despite the fact that this method of laying a little more difficult to install, but in the future you will feel the undeniable advantages of this scheme.

On a note: snail scheme provides full and uniform heating of the floor surface due to the fact that the feed line and the tank line are adjacent to each other. You can easily create the desired bending of the pipe, since for this scheme curvature heating circuit is crucial thanks to the elasticity of the material.

Polypropylene water circuit is laid on the already prepared surface, fixing metal clamps or plastic clip. In order to accelerate the process of installation, you can use a different technique. Basis is laid on a prepared grid with large cells in which the heating pipes are laid. Grid executes immediately and the role of reinforcing the foundations for a future concrete screed.

After laying the polypropylene conduit connected to the distribution equipment. During the test run, checked the place to leaks. Only after verification of the heating circuit under all operating conditions, you can proceed to the equipment concrete screed or stacking the stacked structure.

In custody

Difficulties in the installation of polypropylene pipes there. The material is so convenient and practical work that allows for laying underfloor heating alone. It should be reminded about the details of installation. For floor heating compliance is an important step of laying pipe. By using warm water as a main genders heating pipe must be laid at step 12-15 cm. If desired, make floor heating more intense pipe laying step should be 30 cm.

In emergency situations related to breakthrough the main heating circuit is undergoing renovations. Find place breakthrough polypropylene pipes can use the imager, or using the map - laying scheme heating floors. After removal of the damaged area is cut ties, and replaced with a new fragment. Tightness is achieved by compounds of welding work. Polypropylene pipes in this area is very convenient and practical.