Contents:

- How do I clean the heat exchanger?

- How do I clean a flame tube heat exchanger for a single-circuit boiler?

- Cleaning of two-circuit boilers

- Mechanical cleaning of plate heat exchangers

- How to clean internal surfaces?

- Chemical Cleaning

- How often should I clean the boiler?

Boiler cleaning is an obligatory procedure that must be performed regularly. It is necessary to know how to clean the gas boiler from soot and scale. Scum collects in the heat exchanger passages, and soot - in the smoke channels of the boiler itself and the chimney. Thus, in order to maintain the heating equipment in working condition, it is necessary to clean both the heat exchanger and the smoke channels, as well as the flue and the burner.

How do I clean the heat exchanger?

The cleaning of the heat exchanger depends on its design and on the type of water used in the system: prepared - with special additives - or unprepared.

By design, the heat exchanger can be one of three types:

- bithermic;

- plate;

- fire tube.

The lamellar is divided into two types - primary and secondary( for heating water).Fire-tube heat exchanger is installed in floor boilers, and bithermal - in compact hanging or floor models.

Cleaning can be done in the following ways:

- mechanical;

- chemical;

- electric discharge;

- hydrodynamic,

Council

Maintenance of gas equipment, including boilers, must be performed by specialists with appropriate education. If you do not have enough technical skills, it's better to invite a master.

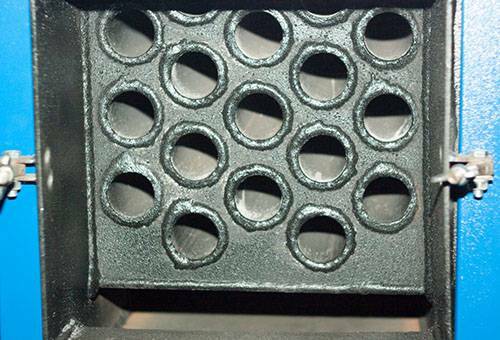

How do I clean a flame tube heat exchanger for a single-circuit boiler?

Cleaning of floor boilers with a flame tube heat exchanger differs from a similar procedure for attachments. Here, for the procedure, the heat exchanger is not removed, but only access to it is ensured.

To perform the work you will need such tools:

- spanners;

- metal brush-ruff;

- hand brush for metal;

- screwdriver;

- natural nap brush or nylon brush.

The first mandatory action is to close the gas supply valve. Then you need to perform three stages of work - providing access to the heat exchanger, cleaning the parts, assembling the boiler. The stages of disassembly / assembly depend on the specific model. How to clean the boilers model MAYAK - 12 KS, you can see in detail in the video.

Cleaning of two-circuit boilers

For boilers with a circuit for heating water, it is mandatory to flush the secondary heat exchanger from the scale inside. Moreover, it should be cleaned more often, because a stream of unprepared water passes through it and salts of hardness( mineral deposits) settle on the walls. The same applies to bithermic heat exchangers. Cleaning of double-circuit boilers is carried out in two stages. The first is mechanical cleaning of the outer surface of parts and chimneys from soot, the second - chemical, hydrodynamic or electric discharge flushing from scale.

Mechanical cleaning of plate heat exchangers

You can clean the boiler from soot without removing the heat exchanger. To do this, it is enough to remove the lid, arm with a rigid nylon brush and close the gas nozzles, so that dirt does not get there. Clearly the whole process is shown in the video:

If the soot has become attached to the surface and is not removed by mechanical treatment with a brush, the heat exchanger is removed and soaked in special cleaning solutions for several hours. Such funds are available for sale in a wide range, as an example, you can bring funds Fauch and MAZBIT +.But you can also use household chemicals - gels for cleaning grills, ovens.

Before disassembling the boiler, it is necessary to disconnect it from the gas, and the ignition switch - from electricity. In addition, it is necessary to drain the water from both the circuits and the expansion tank. The secondary heat exchanger is removed first, it is immediately behind the boiler cover. Primary( main) is more problematic, as it is necessary to disassemble the combustion chamber.

How do I clean internal surfaces?

Flushing of the inner surface of a plate, flame tube or bithermal heat exchanger is possible only with the help of special equipment.

- High pressure pump - hydrodynamic flushing. Used to remove small deposits. Advantages - the speed of the procedure and the possibility of cleaning without removing the heat exchanger.

- Booster( acid-resistant pump) - acid( chemical) flushing. Removes even the old scum. Advantages - removes scale, which can not be removed by other methods. Disadvantages - with improper selection of reagents( acids and neutralizers) reduces the life of the heat exchanger.

- Streamer complex for electric discharge cleaning .Used to remove scale of any strength. Advantages - the metal of the heat exchanger is not destroyed, a high degree of purification is provided. Disadvantages - the noise and duration of the procedure.

Of all these methods at home, only chemical cleaning is possible, since the factory booster can be replaced by a low-pressure pump. The rest of the equipment is both expensive and voluminous, so that such washing of boilers can be carried out only by service centers.

Chemical cleaning

In the presence of a booster, rinsing can be performed independently. The booster can be made by hand - it's a pump and a capacity of 10 liters with two hoses. To help remove the scale, but do not damage the metal surface, it is important to choose the right acid. If the boiler is cleaned regularly, there are small deposits on the pipes, then the best way is to use citric acid. The concentration of the solution is up to 200 g of acid per 5 liters of water.

If the scale is old or unprepared water is used with a high content of minerals( hard water), you need to take more radical means - compositions based on orthophosphoric, sulfuric or hydrochloric acid. Use a hydrochloric acid solution without corrosion inhibitors is not recommended, as this can damage the equipment.

After acid treatment, it is necessary to rinse the heat exchanger with a neutralizer. Alkaline composition is selected based on the acid used. For example, after the citric acid, ordinary baking soda is suitable. If the washing liquid is bought, it is better to buy a neutralizer immediately: usually, firms that produce acid formulations offer alkaline solutions for neutralization.

Flushing video:

How often should I clean the boiler?

The technical documentation for the boiler indicates how often it is necessary to maintain it. For closed circuits with the addition of reagents( single-circuit heating boilers), cleaning is required less often. It can be performed once every 2-3 years. The bi-thermal and secondary heat exchanger must be washed every year, and under difficult operating conditions( "bad" water composition) - twice a year.

Signs that the boiler is in urgent need of cleaning:

- boiler is slowly gaining temperature;

- insufficient traction;

- burner does not light up or burns badly;

- with the same gas consumption the heat output is less;

- traces of soot or partially burnt paint in the viewing window.

Do not neglect the preventive measures, because the result of this can be not only broken equipment, but also a threat to the safety of all tenants at home. Choked smoke channels and pipes with outgrowths inside can cause serious accidents.