Bath is a symbiosis of water and fire. Water in tanks and vats. Fire in the oven. The stove is usually stone, brick. The furnace and fuel loading into the furnace are located in the sauna section. This is not very convenient. And the firewood is filled with water, and the smoke from the firebox goes into the washing room. It is much more convenient if the firebox is located in the dressing room. Only it is necessary not to redo it, but immediately install the stove in a bathhouse with a firebox from the dressing room. The furnace must be designed double-sided.

Read in the article

- 1 Design Options

- 2 Choice of mounting location

- 3 SNiP requirements for construction

- 4 How to install a stove in a bath with a firebox in a dressing room

- 4.1 Foundation arrangement

- 4.1.1 Monolithic deep variant

- 4.1.2 Pile-grillage modification

- 4.1.3 shallow slab

- 4.2 Preparatory work

- 4.2.1 Floor

- 4.2.2 Walls

- 4.2.3 Furnace installation

- 4.2.4 Metal variant

- 4.2.5 Brickwork

- 4.3 Chimney installation

- 4.4 How to bring the firebox through the wall

- 4.1 Foundation arrangement

- 5 Putting the stove into operation

- 6 How to make ventilation in the bath

- 7 Conclusion

Design Options

There are as many options for bath stoves in the world as there are baths themselves. Each owner of the bath wants to realize his ideas and Wishlist. You can buy a ready-made oven or order according to a model, but it's boring, own design is more interesting.

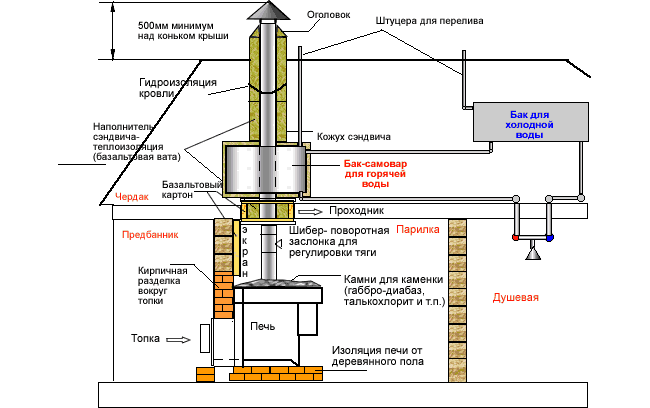

But the furnace is not a simple structure, it must meet certain requirements and rules. Furnaces run on different types of fuel - wood, coal, peat, garbage. Sometimes on gas. Furnaces are built from various materials - brick, stone, metal. The furnace must heat the water - for this you need a tank. It can be removable or built-in. Top or bottom. The tank can be built into the furnace masonry and heated by flue gases. And you can build a kind of samovar. metal passes through the tank chimney, and the hot smoke heats the water in the tank. Furnaces are built both large and small. In the furnace, chimneys are laid out in different ways. The stove can be single-sided - for heating one room or double-sided - for heating two rooms. And the firebox can be located either on one side of the furnace, or on the other.

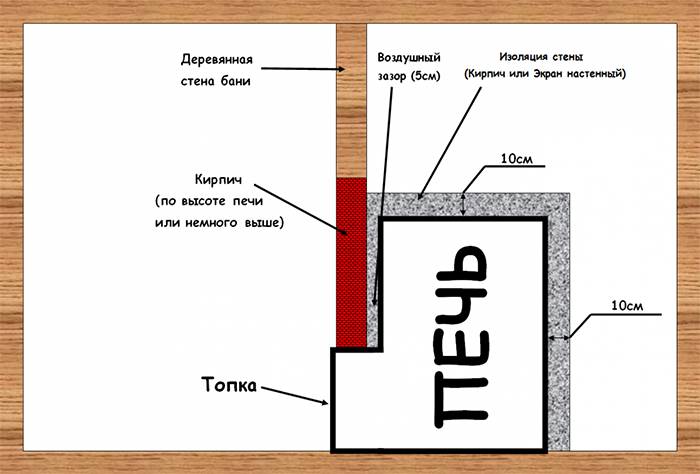

When developing a project sauna stove special attention should be paid to fire safety issues. The furnace is built in a wooden room. It is necessary to build so that the hottest parts of the furnace do not touch the wood. And moreover, thermal insulation made of asbestos or other non-combustible material should be laid in these places.

Choice of mounting location

Still, the main element in the bath is the stove. It produces heat, warms up the entire bath room, heats the water and creates steam. And at the end of the bath session, the stove should dry the steam room. Its effectiveness largely depends on how the stove is located in the bathhouse.

The main requirement for the stove and its placement is dictated by concern for the preservation of health and even the very life of bath visitors. People must be saved from possible burns and death in a fire. The first mandatory rule is that the stove must stand on a solid foundation with a horizontal surface. The floor in the bath must be isolated from the furnace circuit. The edges of the window around the foundation should be edged with sheet iron or asbestos for half a meter. The distance from the stove to any wooden objects must be at least 50 cm. The hottest parts of the furnace body should be covered with non-combustible materials, such as sheet asbestos.

The location of the furnace largely depends on the number of rooms in the bath. If in the bath there is only a dressing room and a steam room combined with a washing room, then this is a cheaper option. If the bath has its own room for each function, then this option is arranged in a completely different way. After meeting the fire safety requirements, the stove can be placed arbitrarily. But the following circumstances must be taken into account. If you put the stove in the steam room, then it will be difficult to maintain it in cramped conditions. The fuel in the steam room is garbage, and the smell of smoke will come out of the furnace in the steam room. In the tightness of the steam room, it is easy to get burned on the stove. If the stove is installed in the washing and steam room, and the firebox with the door is in the dressing room, then problems with garbage leave the main functional area, and the cramped area worries less - the service turns into a more relaxed room.

SNiP requirements for construction

The requirements that must be met during the construction of bath stoves are set out in building codes and regulations (SNiP). Fire requirements for stoves and chimneys are set out in SNiP 2.04.05-91.

The requirement for the main material during the construction of the furnace - the furnace must be built from solid red bricks on clay mortar. The elevation of the furnace above the combustible floor is regulated. The stove should rise above the floor to a height of 140 mm to the ash pan and to the bottom of the gas circulation - 210 mm. A thick metal sheet measuring 70 × 50 cm is laid in front of the furnace door, the large side of which is adjacent to the furnace. There must be a distance of at least 1.25 m from the furnace door to the opposite combustible wall or furniture.

The main requirement is the presence of fire breaks. The adjoining of the furnace close to wooden structures is prohibited. Furnaces and chimneys should be kept at a safe distance from the wooden wall. The furnace wall, insulated with a steel sheet over an asbestos gasket, must be separated from the wooden wall of the house by a gap of 70 to 260 mm.

How to install a stove in a bath with a firebox in a dressing room

The stove must be installed absolutely vertically on a horizontal surface of a good foundation.

Foundation arrangement

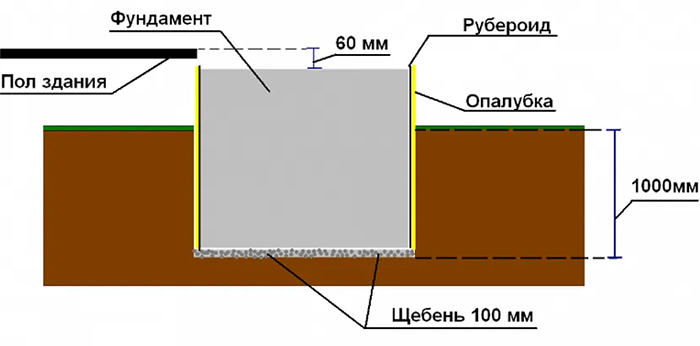

Foundation built completely separate from the foundation of the main building. This is done so that the possible settlement of the house does not damage the foundation of the furnace. Foundations can be built in a variety of ways. The size of the foundation for the stove is determined not only by the weight of the stove, but also by the quality of the soil on which the stove will be built.

Monolithic deep variant

The technology of foundation construction is not fundamentally different from the construction of other foundations. First, markup is done. The foundation is marked in linear dimensions 100 mm more than the base of the furnace. According to the marking, a pit is digging with a depth of about 1 m. The bottom of the pit is covered with sand, which is filled with water and rammed. Then the operation is repeated again. Then crushed stone is added. And formwork is installed in the pit almost to the floor level. The remainder of the height will then be lined with bricks. The formwork along the entire contour is closed with polyethylene. After that, reinforcement is welded from rods with a diameter of 12 mm. The pit is ready for pouring concrete. Concrete mortar is prepared from one part of cement, three parts of sand, five parts of crushed stone and water. Concrete is poured in layers of 20 cm. Each layer is fluffed to remove air from it. Before pouring concrete, the formwork boards must be well wetted so that they do not absorb water from the cement mortar. The finished filling should be covered with plastic wrap for three weeks. Then it will be possible to remove the formwork and fill the empty space with rubble. After drying, the upper surface is covered with a layer of waterproofing, and then two rows of bricks are laid to the floor level.

Pile-grillage modification

The foundation of any kind for the furnace is made independent of the main foundation. If the house begins to slump, then the stove should not notice this. The pile foundation fully satisfies this requirement. In addition, it turns out to be more economical than other options. And another important advantage - driven reinforced concrete pillars, bored reinforced concrete piles and screw rods are fireproof. The lowest foundation costs will be in the case of using screw piles. The pile diameter is selected according to the weight of the furnace. For furnaces weighing no more than 3 tons, rods with a diameter of 89 mm are needed, for 4.5 tons, a diameter of 108 mm is required. Installation of piles does not require special equipment. The pile can be installed by three people.

shallow slab

There are many different slabs on sale that can be used as a foundation for a sauna stove. Japanese-made fiber cement boards belong to the highest class of fire resistance. The appearance of these plates eliminates the need for additional finishing work. The material of the plates withstands sudden changes in temperature and high humidity, does not rot, does not emit harmful substances and is absolutely harmless to humans. Lightweight metal stoves can be installed on stoves.

Preparatory work

The construction of a furnace in a bath is a multi-step technological process. The first step of preparation is at least a sketch of the stove, its placement in the bath, dimensions. For independent work, proven orders are needed.

Floor

The floor in the bath is made either from concrete or from boards. If from boards (according to tradition), then the wood needs strong and dense. This requirement is met by oak, larch and alder. But oak is very expensive. And the other two breeds are not much cheaper. In most cases, the floor is made of pine. Pine flooring is cheap, but not durable. Boards before laying should be dry, humidity - no more than 12%. Floors can be solid or leaky. The first option for water flow should have a slope, but not more than 5%.

Walls

Walls are tricky. If the bath is built of brick, then the inner lining should be wooden. Inside a brick or concrete box, a person will be uncomfortable. If the bath is made of logs or timber, then you can take your time with additional internal lining with boards, for the first time you can start using the bath without it. Partitions between compartments, of course, will be made of boards.

Furnace installation

You first need to choose a stove, there are a lot of sauna stoves that are very different in design, material, size, and cost.

Metal variant

If it is not supposed to arrange crowded meetings in the bathhouse, then it is quite possible to install a metal potbelly stove. You can buy it ready made. It will not keep warm for a long time, but it will warm up quickly. Under the metal furnace does not need a powerful foundation. And the water tank needs to be removable, not built-in. This option is easier to repair. One tank will rust, you can quickly replace it with another.

Brickwork

The brick oven in the bath is a classic. The first and important property of a brick oven is its fire safety. The brick oven is heavy, it weighs one and a half to two tons. Under it, you need a powerful (but also expensive at the same time) foundation. The furnace firebox is laid out of refractory fireclay bricks, the rest of the furnace body is made of red brick. The combustion chamber is laid out as an independent product, without a rigid connection with the body - the coefficients of thermal expansion for fireclay and red bricks are different. The connecting link is fireclay refractory clay, it can withstand high temperatures.

Chimney installation

The chimney must pass through the ceiling in such a way that its hot elements do not come into contact with the wooden structures of the house. A window of the required size is cut in the roof, and the chimney itself is insulated with a protective sheath.

How to bring the firebox through the wall

A stove with a firebox from a dressing room has a whole package of advantages. It heats both the steam room and the dressing room. The steam is light. The steam room itself is not clogged with debris from firewood and from the firebox. There is more free space in the steam room.

The main requirement that must be strictly met is to make sure that heated to high temperatures the surfaces of the elements of the furnace (up to several hundred degrees) did not come into contact with combustible materials in any way when passing through wall. And the partitions between the compartments in an ordinary bath, as a rule, are wooden, that is, combustible. Under the stove itself, you need to put a sheet of refractory material (asbestos or basalt cardboard, for example), on top of which put a sheet of metal. The chimney must be properly routed through the ceiling and roof slabs. Approximately the same requirements for the execution of the passage of the furnace channel through the wall.

A window is cut through the wall. The size of the window should allow the hot channel of the furnace to pass through, lined with bricks with a gap. The width of the window consists of the width of the fuel channel, expansion gaps (1-2 cm on both sides) and a minimum of 25 cm for brickwork. Plus a small gap between brick and wood wall

Putting the stove into operation

A freshly built brick oven cannot be immediately heated to full capacity. First, it is necessary to carry out natural drying for several days with open doors and dampers. Then put a couple of kg of fuel and conduct a test firebox. Then add 1 kg of fuel every day for a couple of weeks.

How to make ventilation in the bath

It is best to have natural ventilation in the bath. You can put the end of a corrugated pipe with a diameter of about 10-15 cm on the floor in one of the corners, and bring its other end to the roof of the bath, about half a meter above the roof ridge. At the top edge of the ventilation pipe, the pressure is less than in the corner of the bath on the floor. In addition, the hot air from the bath itself will be pulled up.

Conclusion

A bath in the country is both a necessity and a great pleasure. In urban areas, this cannot be repeated. And a do-it-yourself bathhouse multiplies this pleasure by the coefficient of pride in your skill. And the whole family will be happy, and friends can be invited.

Hello, thank you for the informative information. Health to you and your loved ones. Sk…

From strong winds, fences sometimes fall if they are installed unreliably. We have our own at Terem-p ...

We bought a summer cottage with a dilapidated country house. They restored it through the tower. AND …

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?

Four days ago I ordered a Revolts heating kit for our dacha. I'm going to pick up tomorrow...

If the apartment is ready, then why doesn’t Buzova broadcast to the whole world about moving and living ...

Like 10m. Enough tape for 1.5m of fence?!

This is most likely an Internet modem like yota. And, I remember, they used both polarizers ...

Wicker fence is a waste of time and money. When we were equipping the site, we bought: up to ...