If a large hole has formed in the metal, you can restore the integrity of the part using welding machine. The result is a homogeneous surface with sufficient strength characteristics. However, not everyone knows how to use welding and has the correct welding consumables available. In some cases, the use of welding equipment is prohibited due to safety requirements. In this case, it is worth figuring out how you can close up a large hole in the metal without welding, ensuring a sufficient level of strength. We invite you to get acquainted with interesting ways. You may want to use one of them.

Read in the article

- 1 We use scotch tape, soda and glue

- 2 How to close a large hole in the metal without welding: we use polyester resin and glass mat

- 3 We use cold welding

We use scotch tape, soda and glue

In the absence or inability to use a welder, you can patch up a hole of significant size using:

- soda;

- glue based on cyanoacrylate;

- scotch tape. It can be of any kind. It is not necessary to take aluminum. The transparent one will quite cope with the task.

We carry out the work in the following sequence given in the table.

| Illustration | Procedure |

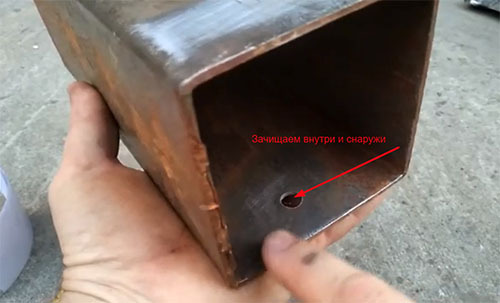

| Preparing the base. We clean the surface with sandpaper. We free from rust not only the surface adjacent to the hole, but also the metal inside the hole. If it is necessary to restore the integrity of the profile pipe, it is worth cleaning the metal from the inside. |

| We tear off a piece of scotch tape. Its area should be sufficient to completely cover the damaged surface. We glue it to the cleaned place on the back side. As a result, the hole should be completely closed. |

| We take the glue prepared in advance. Pour it into the hole. The compound should fill the hole a little more than half. |

| We take baking soda and pour it directly onto the glue. It should completely close the hole and even spill out a little. In the second hand at this time we take the screw. It will be required in the next step. If there is no screw, you can take any other flat metal part, the area of which is less than the area of the hole formed. |

| Using the screw head, we quickly tamp the soda. You should act very quickly and carefully, since the mixture hardens almost instantly. |

| In order for the glue to set as quickly and as strongly as possible, add some more water during the tamping process. At the same time, we do not stop and continue to tamp the composition. |

| Excess mixture, which has hardened on a metal surface, is removed with a file. To obtain an optimal roughness, we additionally use an emery cloth with a suitable grain size. |

Attention! After the above manipulations, a sufficiently strong polymer compound is formed.

A place that once had a hole can be machined with a variety of cutting tools. The above method can also be resorted to when a hole with a larger diameter than required was accidentally drilled initially. After the composition has completely solidified, it is quite possible to drill a hole of the desired size. The polymer compound is designed to withstand this effect. After machining, the surfaces can be painted. This will make it possible to completely hide the defect that was once on the surface.

For those who are skeptical, it is worth noting that in terms of its characteristics, a polymer joint is not inferior to a welded one. It is quite difficult to knock it out and pick it out of the hole. If in doubt, we suggest you verify this personally.

How to close a large hole in the metal without welding: we use polyester resin and glass mat

If the metal is relatively thin, glue, baking soda, and scotch tape will form a polymer bond. However, the hole in the car body is usually repaired by car owners in another way. Naturally, if the welding machine was not at hand. This will require polyester resin and glass mat.

Attention! Instead of glass mat, you can safely use fiberglass. It is more durable, but more expensive.

Having prepared all the materials necessary for the work, we proceed to the direct filling of the hole. This is done in the following sequence shown in the table.

| Illustration | Procedure |

| The area adjacent to the damaged area is brushed to metal. It is necessary to completely remove not only the decorative coating, but also the primer. Using a hammer, the area adjacent to the hole is tapped. This is done around the entire perimeter of the hole to a width of at least 0.5 cm. This will ensure a better and more tight fit of the glass mat to the main surface and exclude removal of the formed joint from a large area during subsequent machining body. |

| Prepare the resin just before installing the patch. The preparation procedure depends on the selected brand. It is worth carefully reading the manufacturer's instructions to add a sufficient amount of hardener. |

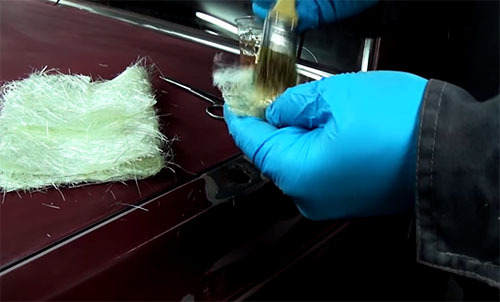

| The prepared mixture is applied to the surface with a brush. The entire area adjacent to the hole should be thoroughly smeared. It is necessary to work with gloves to avoid contact of resin and glass mats with hands. |

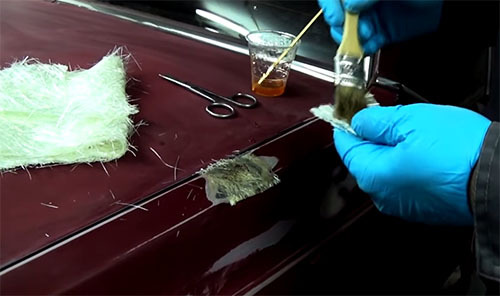

| A patch is cut from the glass mat, the size of which exceeds the area of the hole. To improve the impregnation of the material, the resin is applied to the surface of the glass mat before it is applied to the substrate. After that, we apply the glass mat to the base, ensuring that the hole is completely closed. |

| We apply polyester resin to the material already attached to the surface. The applied composition should be sufficient to completely cover the piece of material and the surrounding area. |

| We prepare a piece of glass mat of the same size. Thoroughly coat with resin. We put it on the previously glued piece of material. Thoroughly coat the second section with resin. If the laid layers are not enough to completely level the surface, the third and subsequent sections are laid. It all depends on how deep the metal was bent in the process of tapping the base with a hammer at the beginning of the process. After that, we leave the patch to dry for a while. To speed up the process, we use a hairdryer. If drops of the composition fall on the adjacent surface, we erase them without letting dry. |

| We remove the excess amount of hardened material from the surface with a grinder. Not all material is cut. A certain amount is left. If passed over the surface, the embedded material should cling to the fingers. |

| We grind the surface. It is advisable to use a special tool. If there is no wheel with a suitable grain size, we grind the base with ordinary sandpaper. |

| Degrease the restored surface, prime, paint. |

We use cold welding

If for some reason fusion welding is not available, we use cold welding.

For this:

- The foundation is being prepared. The metal adjacent to the damaged area is carefully but carefully cleaned with sandpaper.

- Degrease the prepared surface. You can use a rag soaked in solvent or gasoline.

- The composition is being prepared. The procedure for preparing cold welding is detailed on the package. To do this, the composition is squeezed out of the tube, and then thoroughly kneaded in the hands to ensure sufficient plasticity. In the process of the exerted influence, the material will slightly heat up, which is a sure sign of reaching the required consistency.

- The composition neatly and quickly enough closes the hole and the area adjacent to it. Due to the strong adhesion of the composition, small portions of the material should be attached. If it hardens before leveling, it will become unusable.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

"Cold welding is often tough in a limited time."

We hope that the methods we have proposed will help to cope with the situation that has arisen. Which option seems preferable to you, write in the comments. If you have any questions, the HouseChief editors are ready to answer them. Maybe you have your own know-how of sealing holes in metal without welding? Share with our readers. If the article was interesting, rate it. We also offer you to watch the video, in which the author, using a personal example, shows how he, without welding and rivets, repaired a hole in the bottom of the car.